Shield machine cutter wear simulation testing device and method for upper-soft lower-hard stratum

A shield machine tool and simulation test technology, applied in the field of shield machine detection, can solve the problems of increasing construction cost, high risk, delaying construction fluency and construction period, etc., to reduce construction cost, improve construction progress and efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical content of the present invention will be further described below, but it is not intended to limit the essence of the present invention.

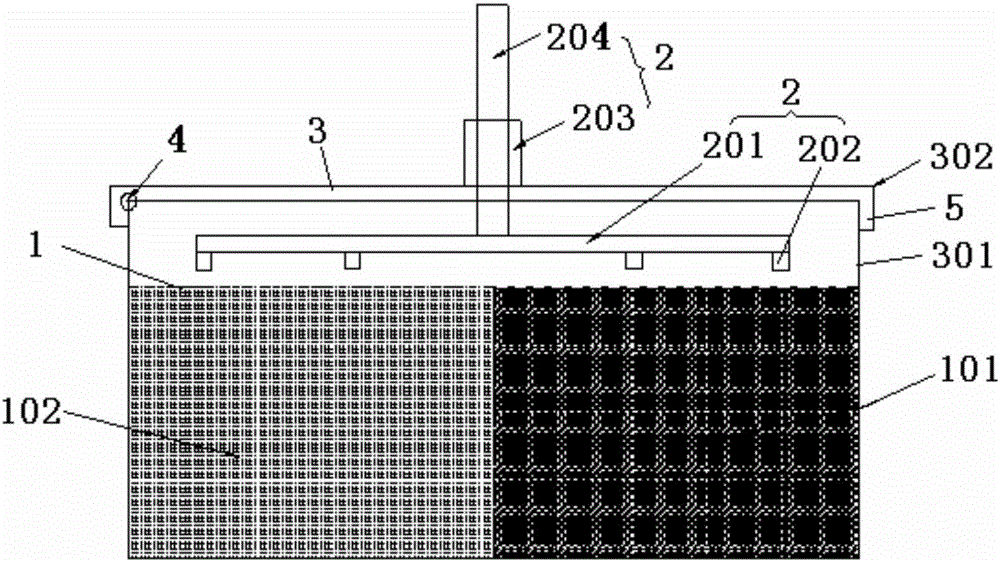

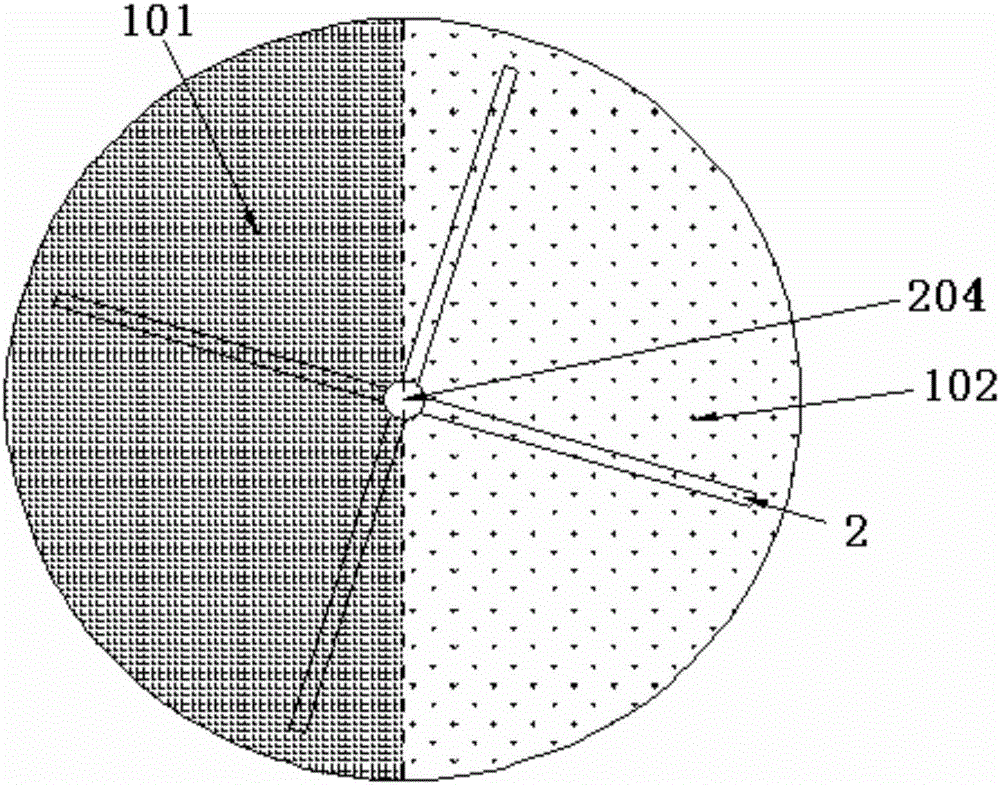

[0023] figure 1 It is one of the structural schematic diagrams of the shield machine tool wear simulation test equipment for upper soft and lower hard formations according to the embodiment of the present invention; figure 2 It is the second structural schematic diagram of the shield machine tool wear simulation test equipment for the upper soft and lower hard formations according to the embodiment of the present invention.

[0024] Such as figure 1 and figure 2 As shown, the shield machine tool wear simulation test equipment for the upper soft and lower hard formations of this embodiment includes a simulated soil 1 for simulating the soil state of the upper soft and lower hard formations on-site investigation and a shield machine for simulating The shield cutterhead simulation device 2 is partly rotated and propell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com