Adaptive abrasive slurry jet mining system and method

A technology of abrasive slurry jet and mining method, which is applied in the field of water jet system, can solve problems that are difficult to overcome, cannot cope with thin coal seam mining, small body, etc., and achieve the effects of reducing tool wear, wide practicability, and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

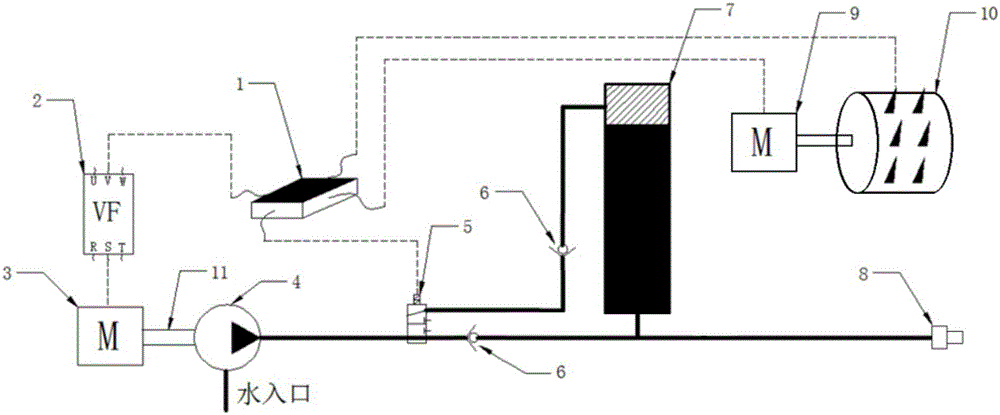

[0017] Such as figure 1 As shown, the adaptive abrasive slurry jet mining system of the present invention, the adaptive abrasive slurry jet system includes a single-chip microcomputer 1, a frequency converter 2, a motor 3, a water pump 4, a solenoid valve 5, a one-way valve 6, an abrasive tank 7, and a nozzle 8. Drive motor 9 and drum 10; the coal mining drum device formed by drive motor 9 and drum 10 is connected to single-chip microcomputer 1, and the model of said single-chip microcomputer is STC12C5A60S2, and single-chip microcomputer 1 is connected with abrasive slurry mixing water spraying device, and said material The mixing water spray device includes a motor 3 connected to the single-chip microcomputer 1 through a frequency converter 2, the motor 3 is connected to a water pump 4 through a coupling 11, the water outlet of the water pump 4 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com