Image-based on-line detection and compensation system and method for cutting tools

A compensation method and tool technology, applied in the field of tool processing, can solve problems such as implementation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described below in conjunction with the accompanying drawings. It should be understood that the following examples are illustrative only and not limiting.

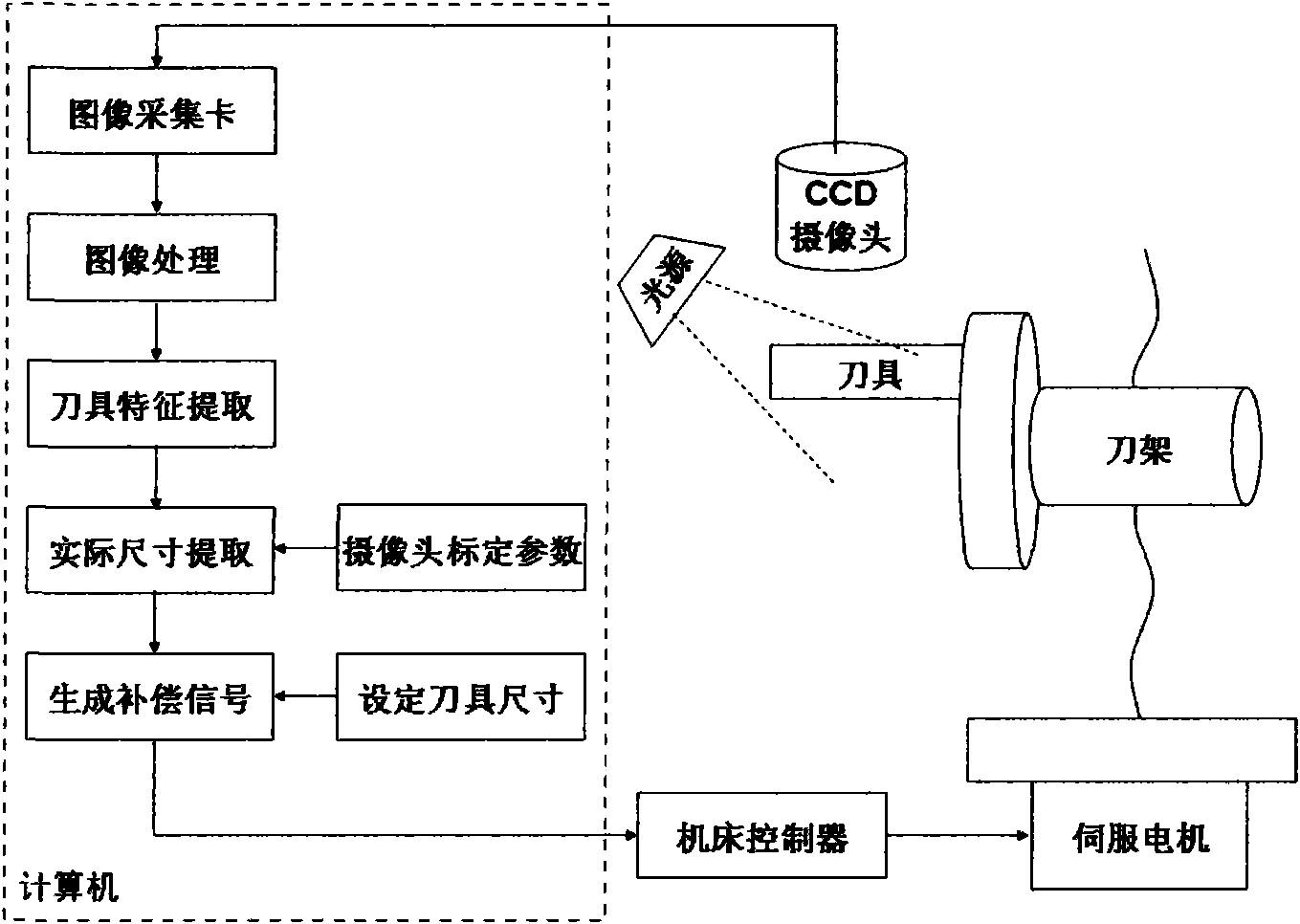

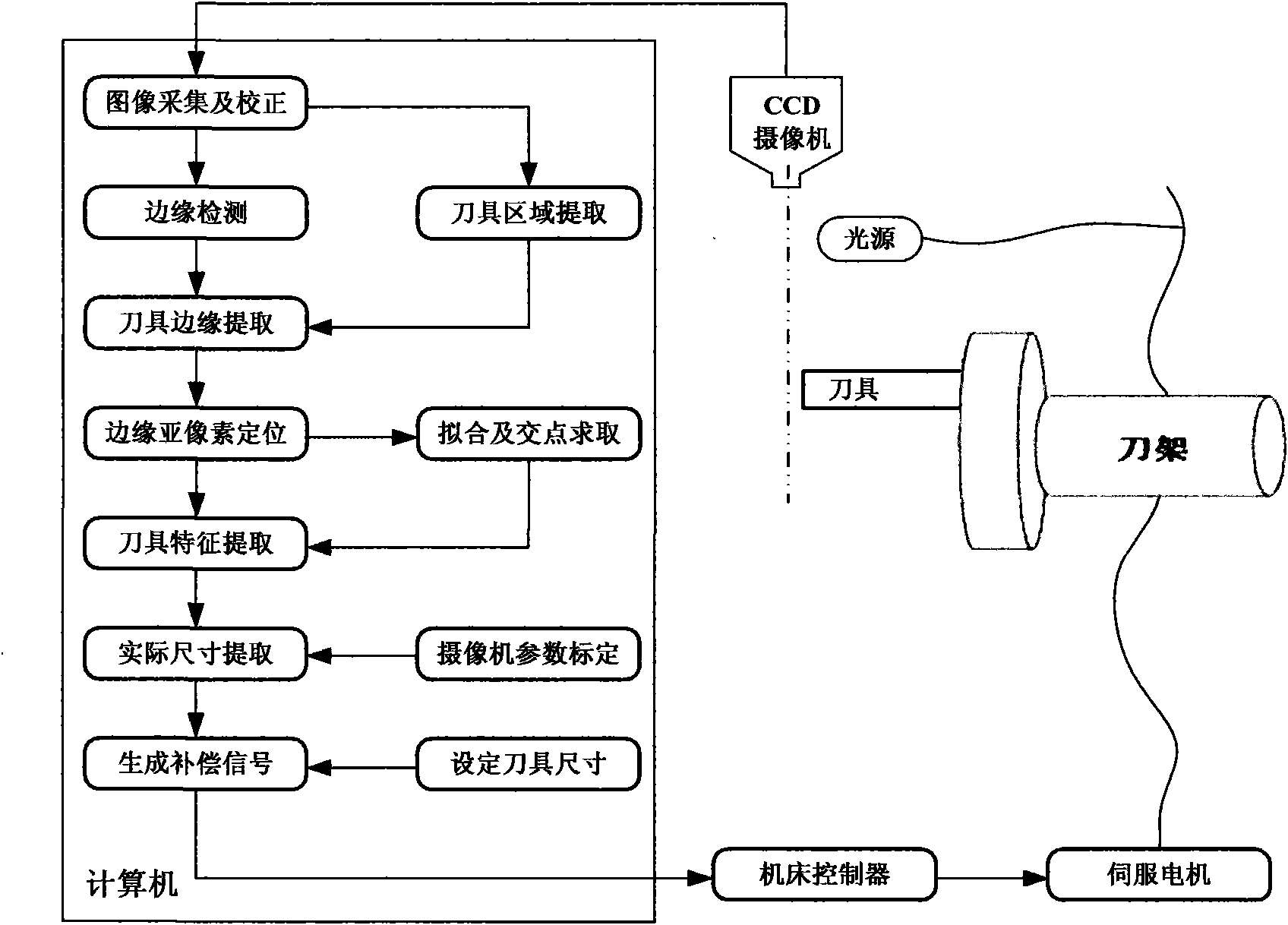

[0017] refer to Figure 1-6 , to illustrate the system and method for online tool image detection and compensation of the present invention.

[0018] The working process of the online detection and compensation system of the present invention is as follows:

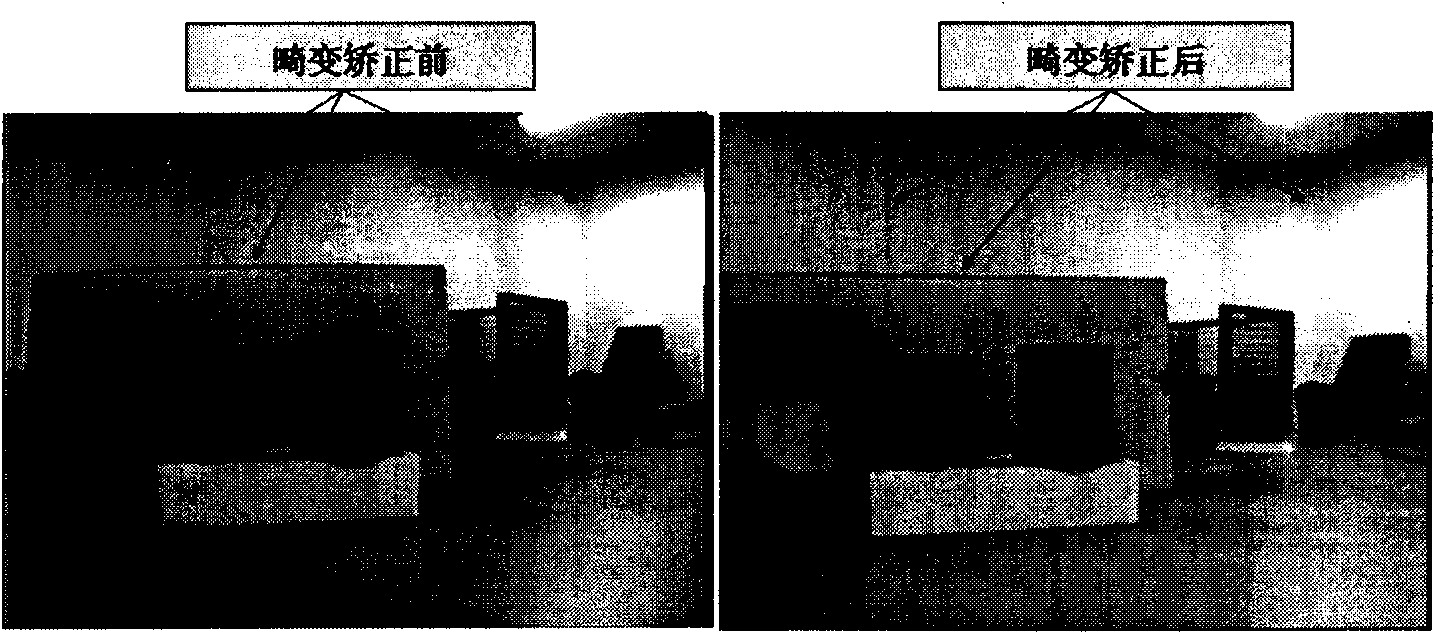

[0019] (1) An imaging device is arranged, and an image of a tool installed on a machine tool is captured by the imaging device. Before the tool processing on the lathe starts, the CCD camera is used to obtain the current shape image of the tool at a given position with the cooperation of the auxiliary light source. Preferably, the camera is periodically collected in the process of acquiring the image of the tool shape, for example, a preset processing time can be set, and when the tool cuts for a certain long time, the image of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com