Cutting tool wear measurement method based on vibration spectrum and neural network

A tool wear and neural network technology, applied in the direction of measuring/indicating equipment, manufacturing tools, metal processing machinery parts, etc., can solve the problems of low detection accuracy and complex detection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

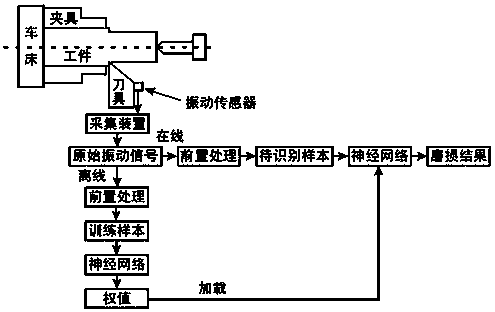

[0023] like figure 1 As shown, the tool wear detection method based on vibration spectrum and neural network of the present invention includes the following steps.

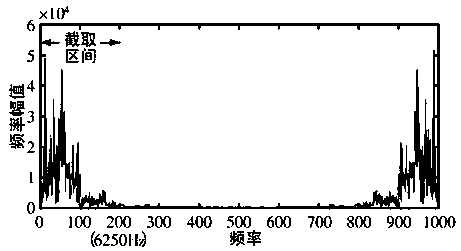

[0024] Step 001. Connect the vibration sensor to the tool handle of the turning tool near the tool head. The supporting equipment for the vibration sensor also includes a signal conditioner and a data acquisition card. The data acquisition card collects the original vibration signal and transmits the signal to the computer. The effective frequency band of the vibration signal during metal cutting generally does not exceed 8000Hz. When collecting the vibration signal, the collection frequency is set to 31250Hz to ensure the smooth collection of useful information.

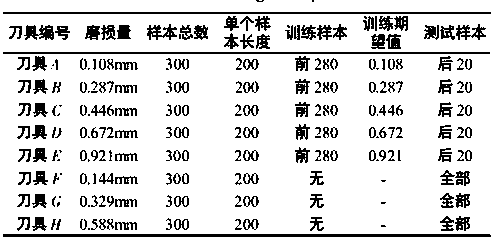

[0025] Step 002. Use the same 8 turning tools for actual cutting, and use the average value of the width of the wear zone in a certain range on the 1 / 2 of the flank as the tool bluntness standard, and obtain the wear amount of 0.108mm (A) and 0.287mm ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com