Friction-loss and vibration analog experimental equipment for main motion components of IC engine

A technology for simulating testing and moving parts, which is applied in the direction of internal combustion engine testing and testing of wear resistance, etc., can solve the problems of high cost, complex structure, long test period, etc., and achieve the effect of high test efficiency, low cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

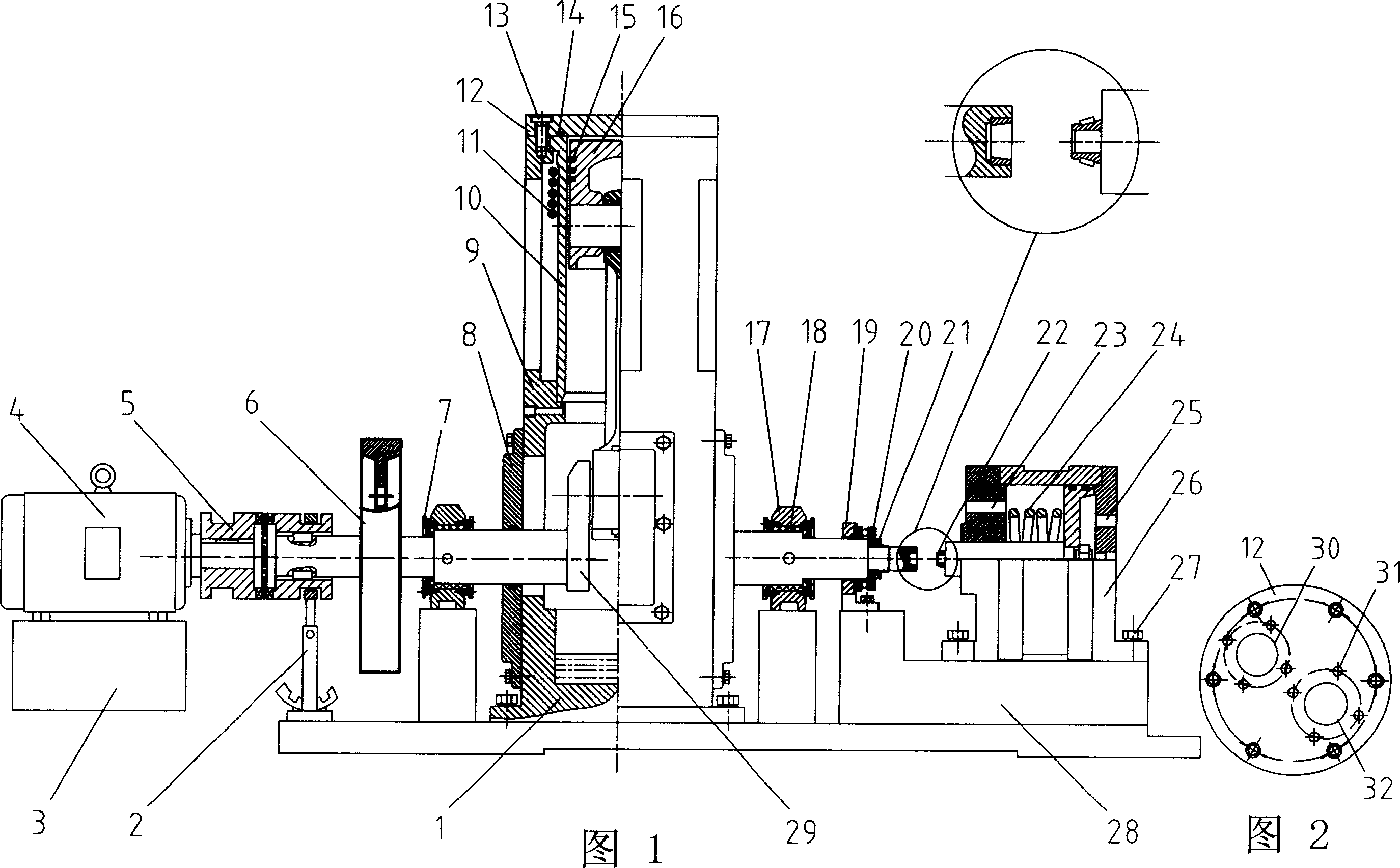

[0015] The invention relates to a friction and wear and vibration simulation test machine (hereinafter referred to as the test machine) used for main moving parts of an internal combustion engine (including cylinder liners, piston rings, crankshafts, bearings, etc.). It simulates the surface wear and vibration of the main moving parts in the actual working environment, so as to study the friction and wear mechanism of the main moving parts of the internal combustion engine under different working conditions, and can comprehensively evaluate the materials of the main moving parts by changing the test parameters and comparative tests related performance.

[0016] The structure of the testing machine is shown in Figure 1 and Figure 2: including the driving part and the simulation test part.

[0017] 1. Drive part:

[0018] A main drive mechanism is provided, which is composed of a cylinder 10, a piston ring 15, a piston 16, a crankshaft 29, and an exhaust port 30 and an air inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com