Method and device for monitoring the wear of sliding electrical contacts of a rotating commutator for an automotive vehicle

A technology of triboelectric contact and current commutator, which is applied in the direction of rotary collector, electronic commutation motor control, control purpose model/simulation, etc. It can solve wear and tear, loss of electrical contact, stop of vehicle network power supply, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

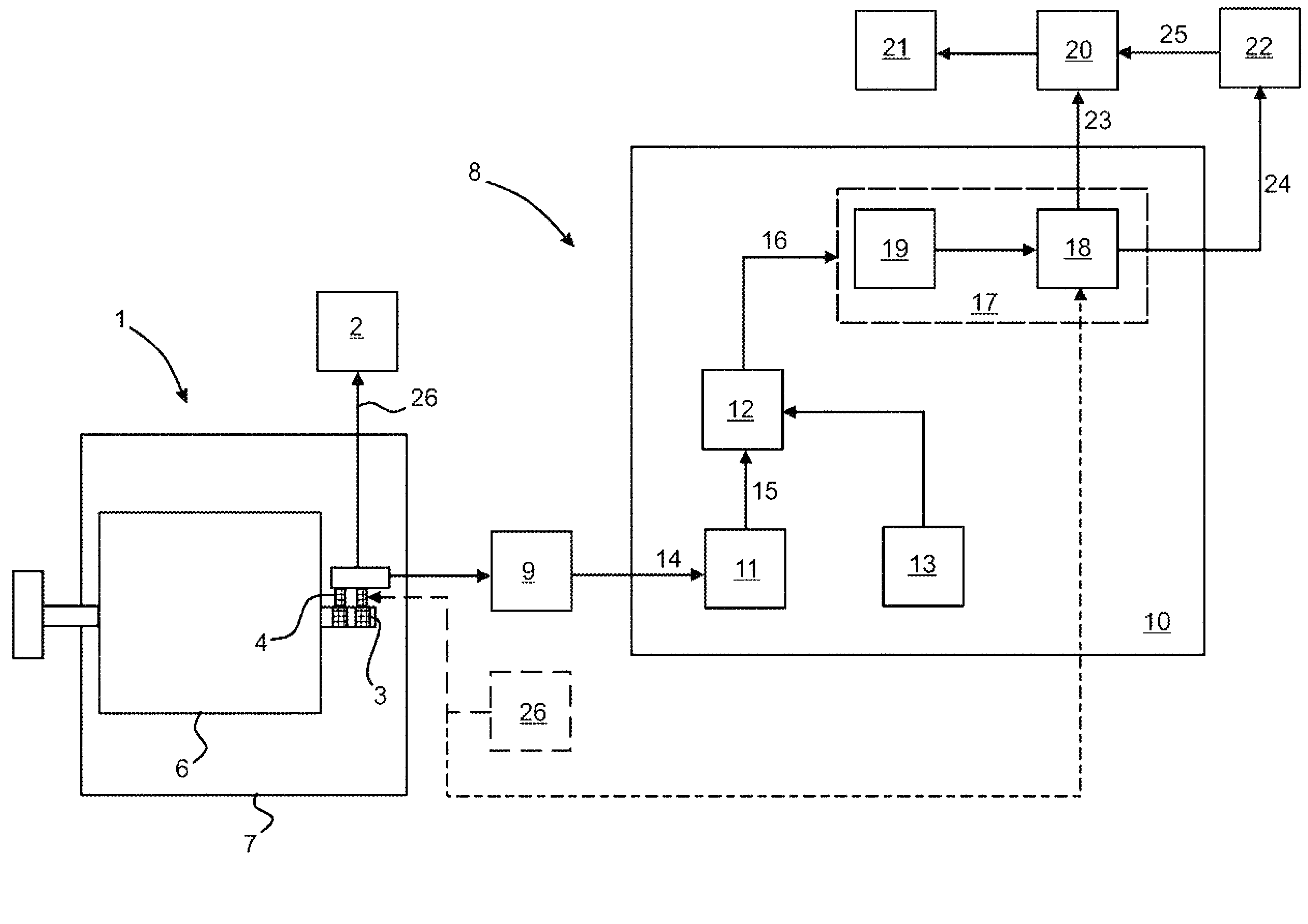

[0024] In the only figure, a generator electric machine 1 is mounted on a motor vehicle for supplying equipment 2 of this vehicle, in particular a rechargeable energy store and via an on-board vehicle associated with the electric machine and / or the rechargeable energy store Mains powered accessories. The electric machine 1 is equipped with a rotating current commutator 3 comprising triboelectric contacts 4 (eg brushes etc.) cooperating with corresponding traces 5 in order to electrically connect the rotor 6 to the power supply of the equipment 2 of the vehicle Loop 26. In order to prevent the significant wear of the triboelectric contact 4 from adversely affecting the equipment of the vehicle, the motor 1, especially the rotating current commutator 3, and the monitoring device for monitoring the wear of the triboelectric contact 4 by analyzing the current generated by the motor 1 8 related.

[0025] More particularly, information about the current generated by the motor 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com