Processing method of high-strength bolts

A technology of high-strength bolts and processing methods, applied in the field of bolt processing, can solve problems such as breakage or cracks, easy rust and corrosion, and formation of accident sources, so as to achieve the effect of improving strength, not easy to break, and meeting the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

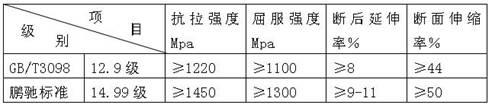

[0032] The processing method of high-strength bolts can manufacture 14.9 and 12.9 grade bolts. First of all, in the selection of materials, it is necessary to ensure the realization of the tensile strength, hardness value, yield strength, elongation and shrinkage that must be achieved by high-strength bolts, and achieve various indicators through non-cutting cold extrusion processing, 12.9 / 14.9 high strength The processing steps of bolts are as follows:

[0033] 1. Material selection

[0034] The material is selected as the plate element material, with SCM440 and SCM435 to produce 12.9-grade bolts, and 42CrMoVNb to produce 14.99-grade high-strength bolts.

[0035] Selecting a correct and suitable material is the prerequisite for measuring the comprehensive mechanical properties of high-strength fasteners. In order to improve the tensile strength, hardness, yield strength, elongation after fracture, and reduction of area of high-strength bolts, this method adopts Baosteel SC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com