Steel with underrelaxation and hydrogen corrosion resistance for high-speed railway prestressed pull rod and production method thereof

A technology of prestressed tie rods and high-speed railways, applied in the production of prestressed tie rods for ballastless track slabs of high-speed railways with a speed of 350 km/h, and in the field of billet continuous casting medium-carbon and high-silicon micro-alloyed quenched and tempered prestressed tie rods , can solve the problems of high-carbon steel wire rod not meeting the index requirements, affecting the fatigue performance of the steel wire, and prone to cracks on the surface, and achieve the effects of stable comprehensive mechanical properties, good hardenability, and good fluidity of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

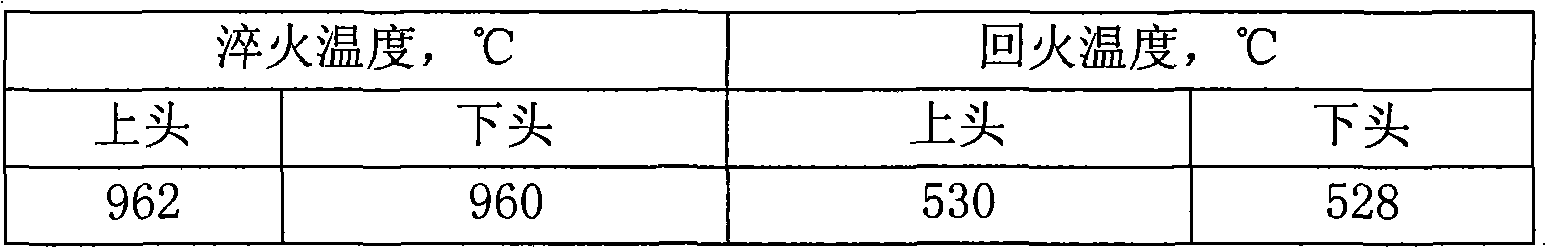

[0026] Embodiment 1: furnace number 9B03010

[0027] For converter smelting, the amount of raw material molten iron added is 75 tons, steelmaking pig iron is 11.5 tons, steel scrap is 4.5 tons, the working oxygen pressure of oxygen supply is 7kg / cm2, the oxygen supply time is 17 minutes and 35 seconds; the consolidated pellets are 806kg. The amount of lime added is 4824kg, lightly burned dolomite is 1664kg; Austrian ore is 1761kg; end point carbon: 0.27%, phosphorus: 0.013%; tapping temperature is 1613°C.

[0028] Deoxidation alloying, silicon calcium barium 250kg, silicon manganese 500kg, ferrosilicon 1550kg, carbon ferrochrome 500kg.

[0029] For LF refining furnace, the flow rate of argon gas in the early stage is 510Nl / min, the flow rate in the middle stage is 300Nl / min, and the flow rate of argon gas in the later stage is 50Nl / min.

[0030] 5# caster, tundish temperature 1515°C, crystallizer water volume 1657L / min, casting speed 1.75 / min.

[0031] Tundish smelting compo...

Embodiment 2

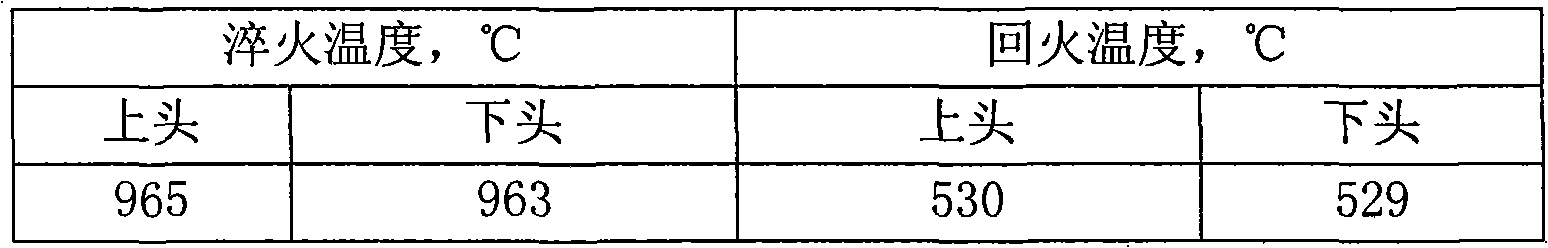

[0039] Embodiment 2: furnace number 9A03157

[0040] Converter smelting, raw material molten iron added 74 tons, steelmaking pig iron 10.9 tons, scrap steel 4.7 tons, oxygen supply working oxygen pressure 7.5kg / cm2, oxygen supply time 16 minutes 33 seconds; consolidated pellets 1306kg. The amount of lime added is 4424kg, lightly burned dolomite is 1854kg; Austrian ore is 1488kg; endpoint carbon: 0.22%, phosphorus: 0.013%; tapping temperature is 1613°C.

[0041] Deoxidation alloying, silicon calcium barium 250kg, silicon manganese 500kg, ferrosilicon 1550kg, carbon ferrochrome 500kg.

[0042]For LF refining furnace, the flow rate of argon gas in the early stage is 490Nl / min, the flow rate in the middle stage is 330Nl / min, the flow rate of argon gas in the later stage is 50Nl / min, the synthetic slag is added 600kg, the submerged arc slag is 300kg, and the outbound oxygen activity is 17ppm.

[0043] 5# caster, tundish temperature 1508°C, crystallizer water volume 1659L / min, cast...

Embodiment 3

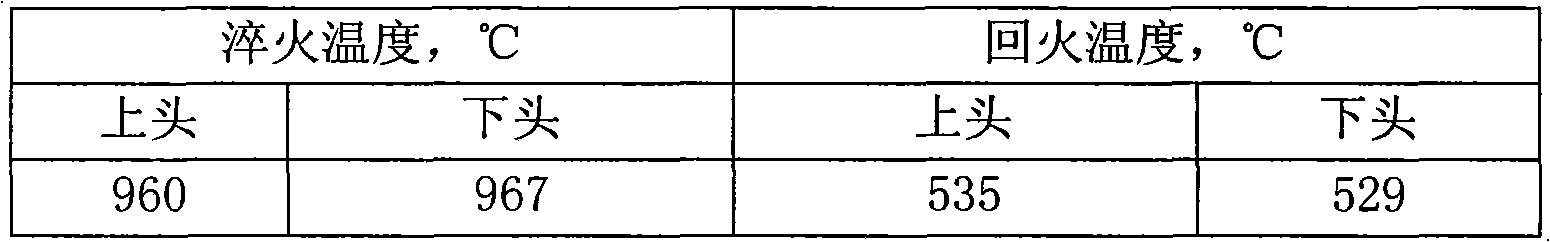

[0053] Embodiment 3: furnace number 9A03158

[0054] For converter smelting, the amount of raw material molten iron added is 73.5 tons, steelmaking pig iron is 11.2 tons, steel scrap is 4.8 tons, the working oxygen pressure of oxygen supply is 7kg / cm2, the oxygen supply time is 14 minutes and 23 seconds; the consolidated pellets are 666kg. The amount of lime added is 4824kg, lightly burned dolomite is 1664kg; Austrian ore is 1162kg; endpoint carbon: 0.30%, phosphorus: 0.01%; tapping temperature is 1613°C.

[0055] Deoxidation alloying, silicon calcium barium 250kg, silicon manganese 500kg, ferrosilicon 1550kg, carbon ferrochrome 500kg.

[0056] For LF refining furnace, the flow rate of argon gas in the early stage is 460Nl / min, the flow rate in the middle stage is 330Nl / min, and the flow rate of argon gas in the later stage is 50Nl / min.

[0057] 5# caster, tundish temperature 1519℃, crystallizer water volume 1657L / min, casting speed 1.75 / min.

[0058] Tundish smelting compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com