Water-liquid nitrogen alternate fatigue fracturing and heat collection rate improving method for hot dry rock

A technology of hot dry rock and liquid nitrogen, which is applied to collectors, mining fluids, and earthwork drilling and mining using groundwater as a working fluid. It can solve problems such as clogging of cracks and cracks, and achieve avoidance of danger, high cost, and low temperature. , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

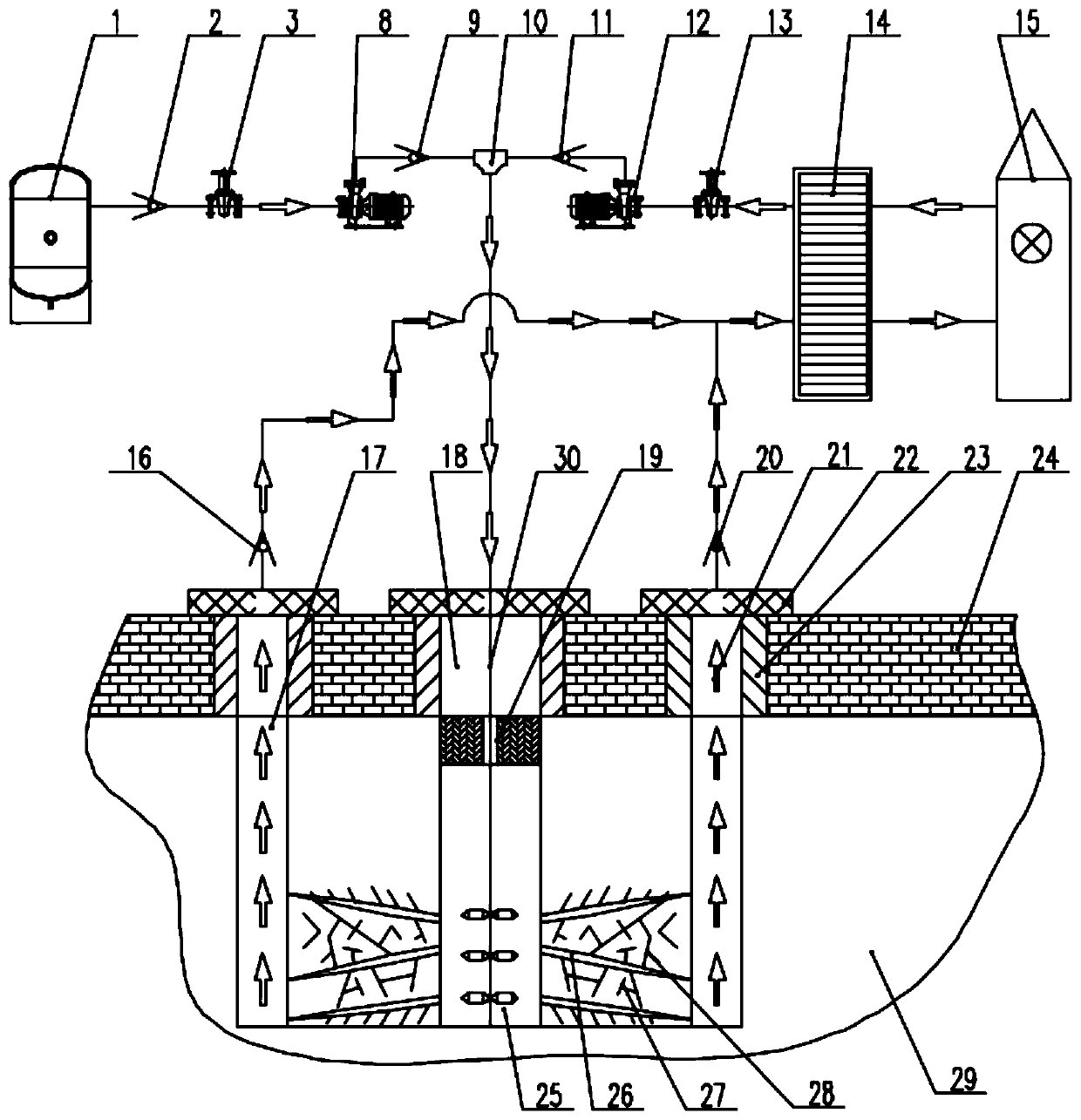

[0023] Such as figure 1 As shown, in the determined hot dry rock geothermal development area, adopting the method of the present invention intends to take geothermal energy in the dry hot rock layer at a depth of 3000m. Firstly, drilling equipment is used to construct the rock formations to build injection well 18, production well A17 and production well B21, so that the horizontal distance between injection well 18, production well A17 and production well B21 is 1000m-1500m respectively. Then use the method of the present invention to artificially create fractures in the hot dry rock formation, so that a huge fracture zone is formed between the injection well 18, the production well A17, and the production well B21. After the fracture is completed, a large amount of normal temperature or low temperature water is injected into the injection well 18 to fully exchange heat with the hot dry rock in the fracture zone, and then high temperature water or steam above 200°C is obtaine...

Embodiment 2

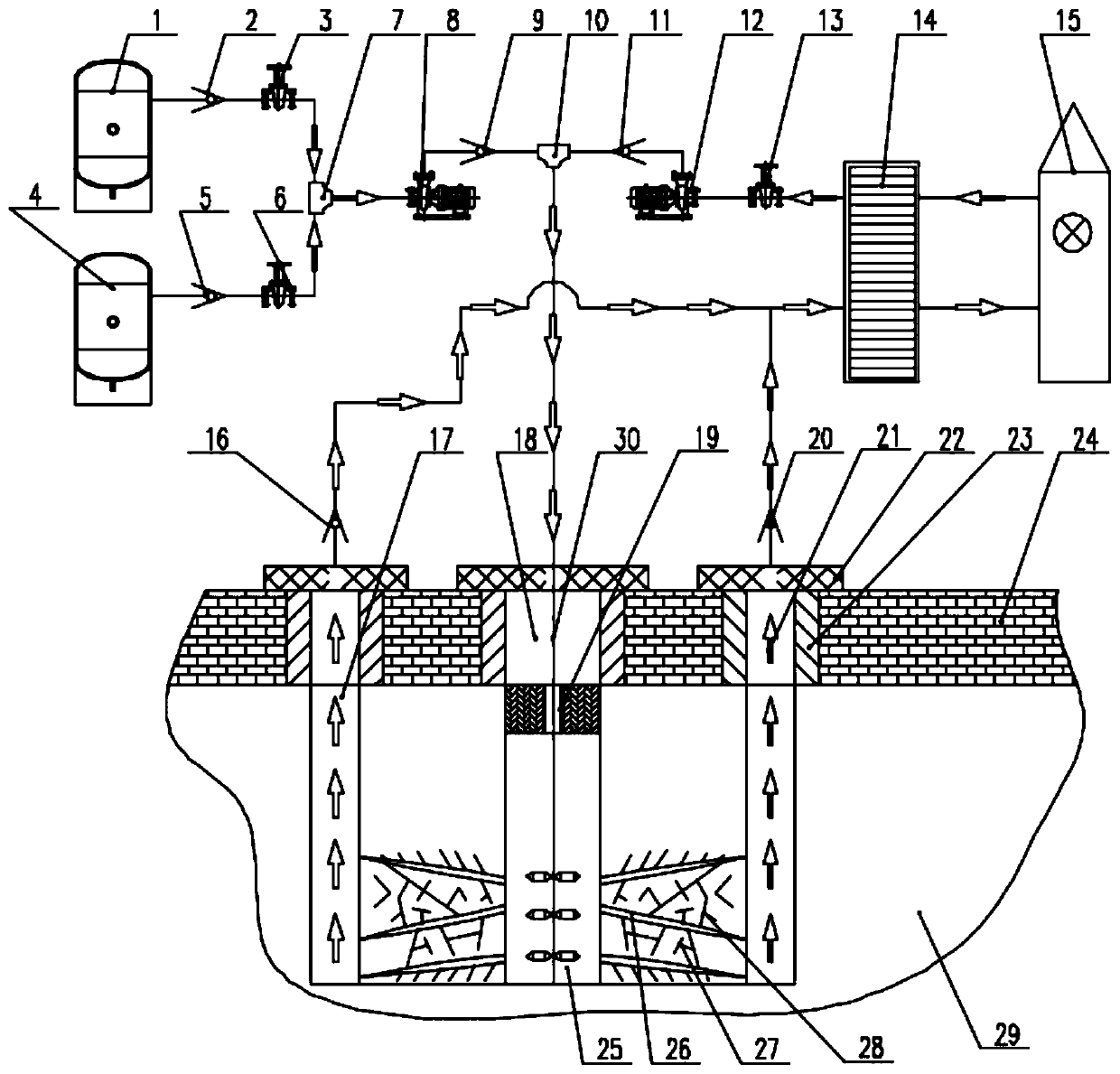

[0037] Such as figure 2 As shown, different from Example 1, the liquid nitrogen fracturing system also includes a liquid nitrogen tank B4, a gate valve B6 and a tee A7, and the outlet of the liquid nitrogen tank A1 passes through an inlet of the gate valve A3 and the tee A7 The outlet of the liquid nitrogen tank B4 is connected to the other inlet of the three-way A7 through the gate valve B6, and the outlet of the three-way A7 is connected to the inlet of the liquid nitrogen booster pump 8; the liquid nitrogen tank B4 is connected to the gate valve B6 A one-way valve B5 is provided on the connecting pipeline between them.

[0038] After the liquid nitrogen in the liquid nitrogen tank A1 is injected, switch the three-way A7, open the one-way valve B5 and the gate valve B6, and use the liquid nitrogen tank B to provide liquid nitrogen to ensure uninterrupted fracturing work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com