Longitudinal-transverse type core wound rail sampling and fracture analysis method

An analysis method, a vertical and horizontal technology, applied in the field of sampling and fracture analysis of vertical and horizontal nuclear damage rails, can solve the problems of no relevant literature on the sampling method and fracture analysis method of vertical and horizontal nuclear damage rails, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The steps of the method of the present invention are as follows:

[0028] Step S1: Detect the position of the transverse fatigue crack inside the rail head of the vertical and horizontal nuclear damage rail.

[0029] Use the ultrasonic flaw detection method to determine the position of the transverse fatigue crack inside the rail head of the nuclear damaged rail, and record the position.

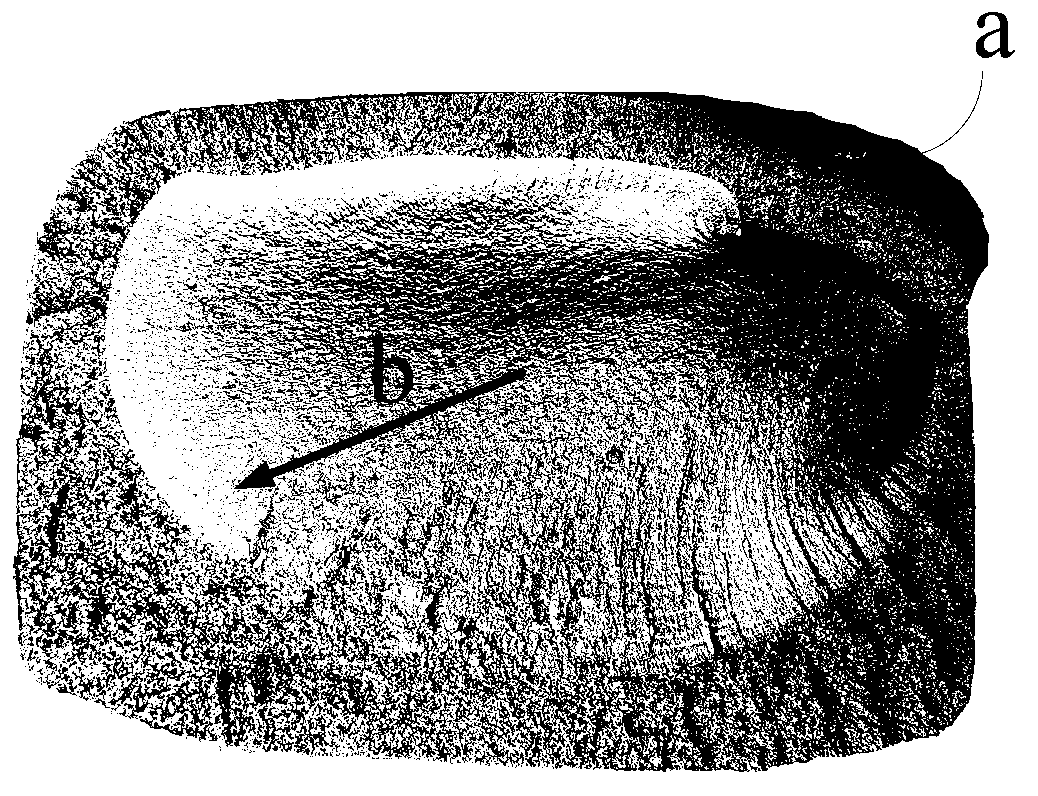

[0030] Step S2: Press open the transverse fatigue cracks inside the rail head to expose the transverse fatigue fracture of nuclear damage, observe the macroscopic morphology of the transverse fatigue fracture and determine the type of nuclear damage.

[0031] Press open the transverse fatigue cracks inside the rail head by machining to expose the nuclear transverse fatigue fracture, observe the fatigue source of the transverse fatigue fracture (that is, the minimum radius of the fatigue arc) and the dispersion direction of the radial stripes perpendicular to the fatigue arc. Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com