Device and method for multi-axis fretting fatigue test of steel wire

A technology of fretting fatigue and testing equipment, which is applied in the direction of measuring equipment, using stable tension/pressure testing material strength, instruments, etc., can solve the multi-axis fretting fatigue damage evolution and fracture mechanism that are not suitable for slender flexible body steel wires and other problems, to achieve the effect of avoiding sudden drop of contact load, wide practicability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

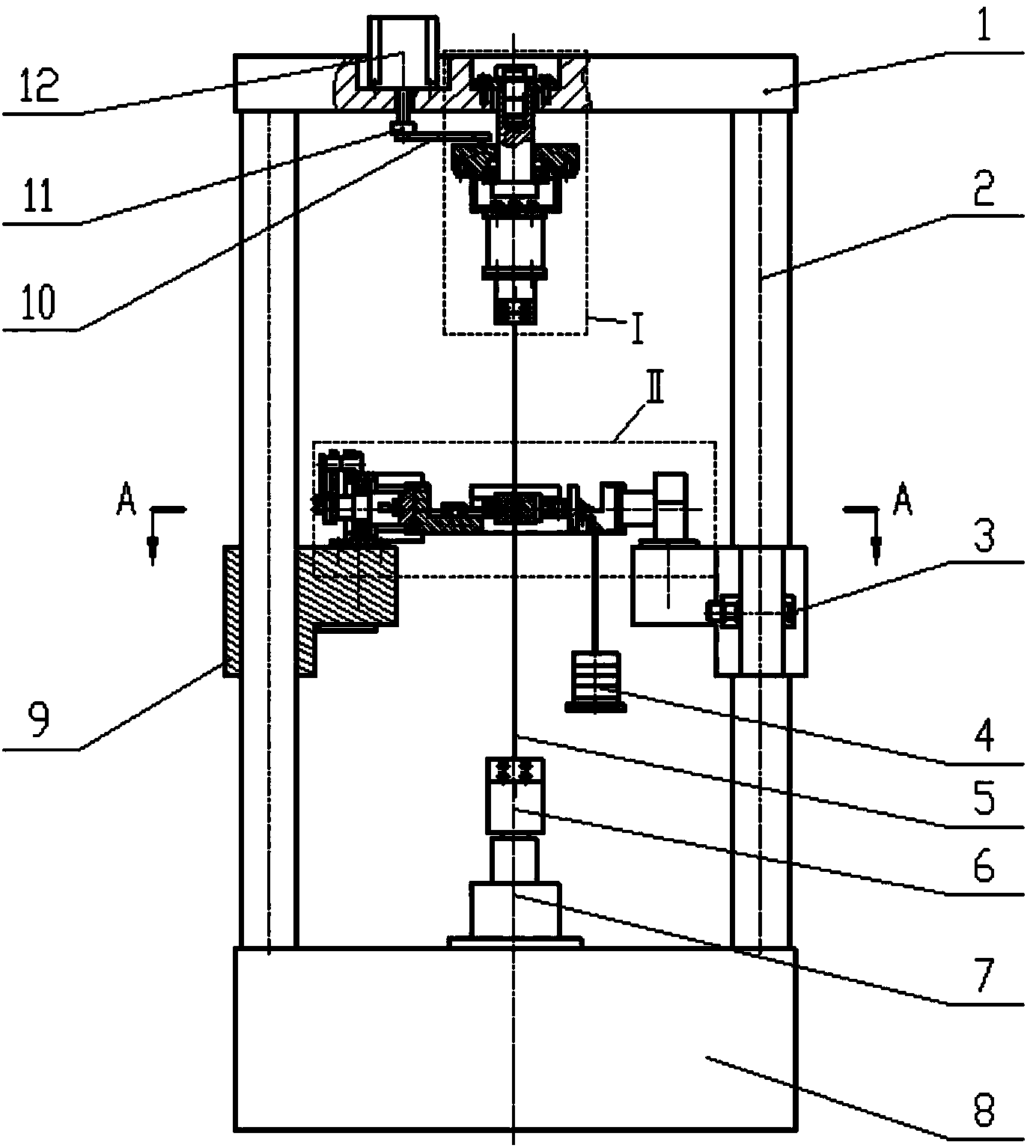

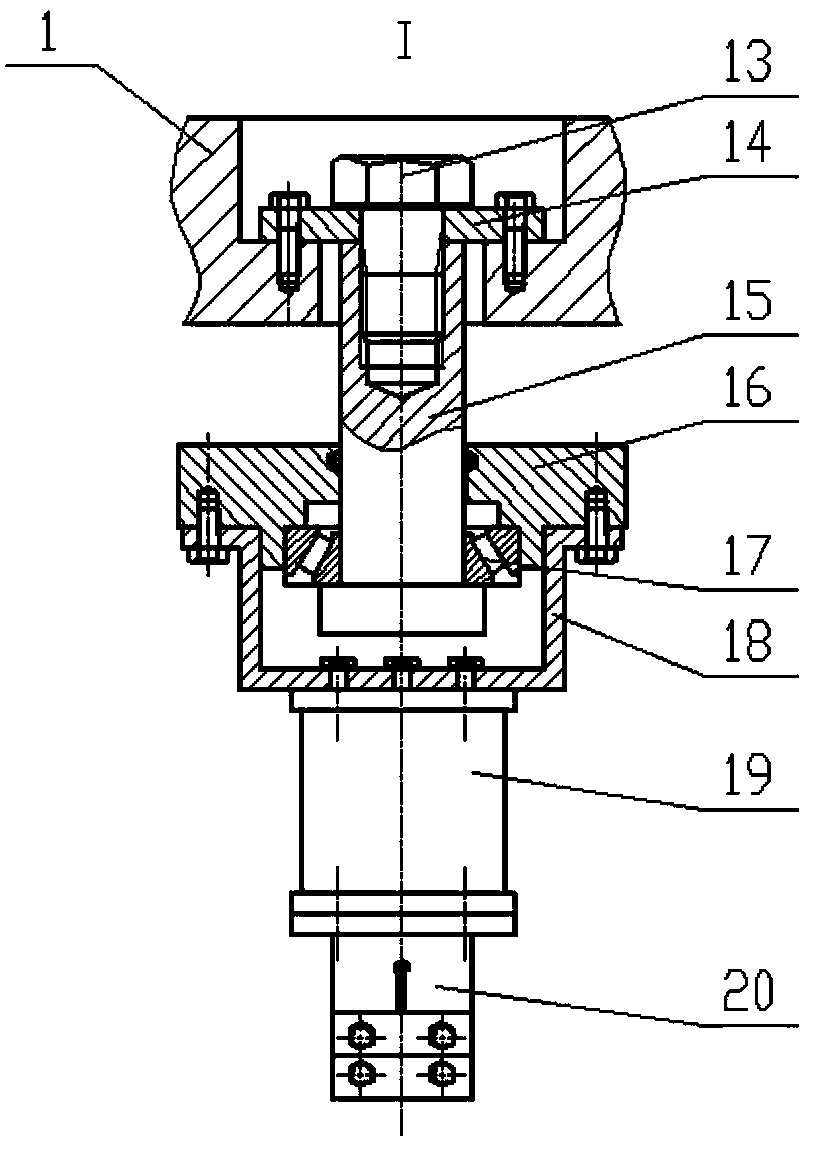

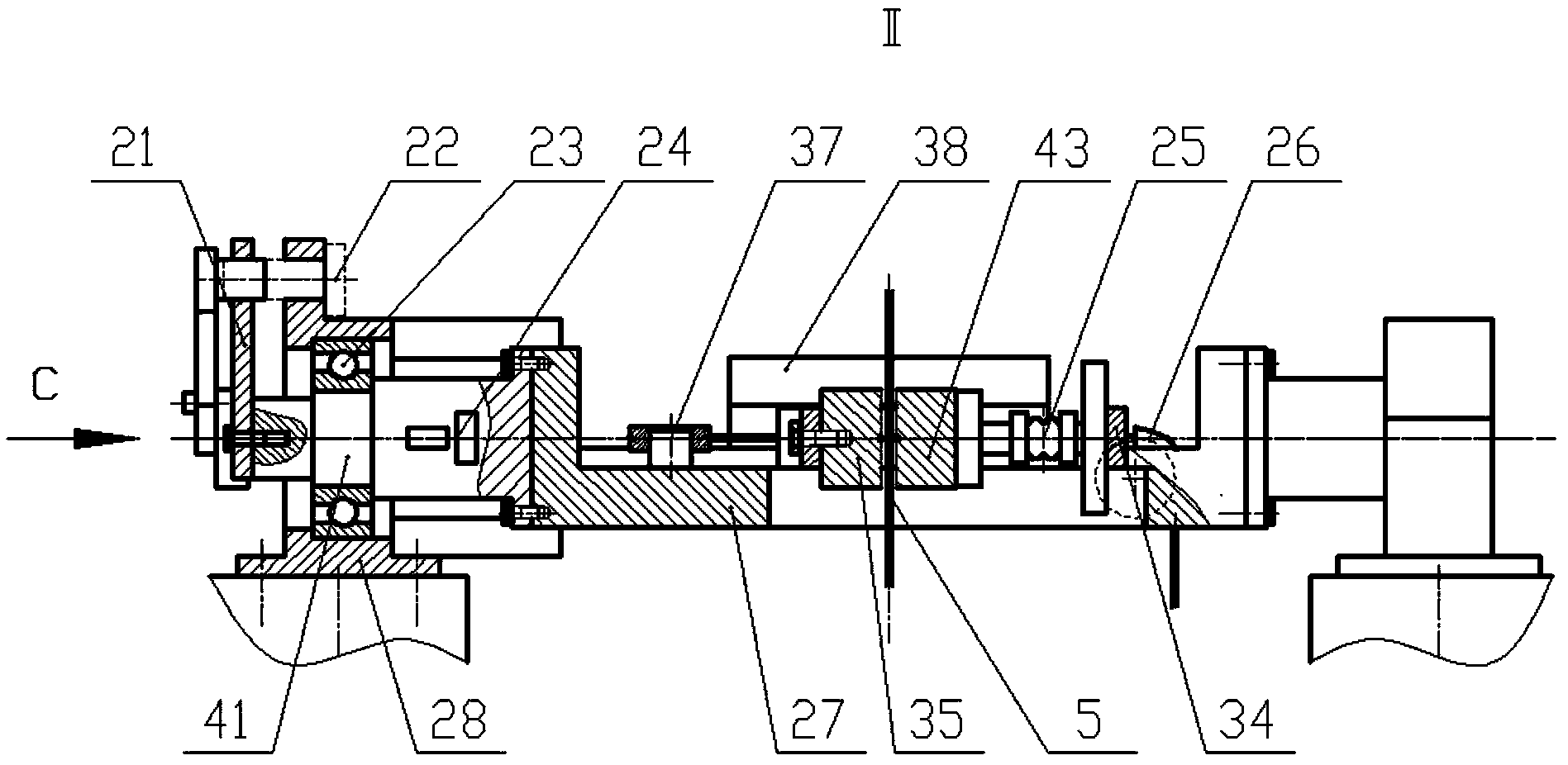

[0042] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0043] Such as Figure 1-6 As shown, the steel wire multi-axis fretting fatigue test device of the present invention is mainly composed of a base frame, a tension-torsion fatigue system, a swing loading system, a fatigue steel wire 5, and a state monitoring system;

[0044] Described pedestal comprises base 8, the support column 2 that is symmetrically arranged on base 8, the bearing beam 1 that is arranged on the top of support column 2, the support clamp block 9 that places support column 2 middle parts; Described support clamp block 9 is The split-type block with circular arc holes is fixed to the middle of the support column 2 by the bolt 3, and the support clamp 9 on the side near the fatigue steel wire 5 has a semi-cylindrical boss with a fixed bearing support 28;

[0045] The tension-torsion fatigue system includes a support system arranged on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com