Method for predicting remaining useful life of steel box girder bridge top plate-longitudinal rib welding detail

A technology for steel box girders and details, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, measuring devices, instruments, etc., can solve problems such as fatigue crack development that cannot be considered in welding details, and achieve overcoming subjectivity and blindness and implementability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

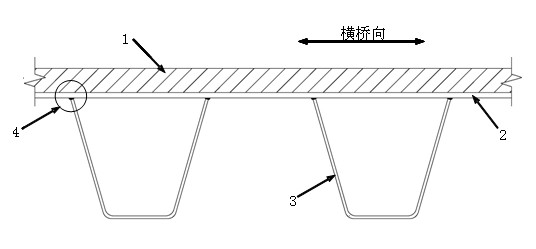

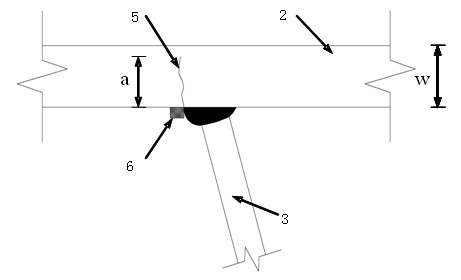

[0024] 1 pair figure 1 For the steel box girder bridge roof-longitudinal rib welding detail 4 shown, the fatigue crack 5 is detected by ultrasonic non-destructive testing technology, the location of the welding detail where fatigue cracking occurs is determined, and the expansion depth a of the fatigue crack 5 in the roof is measured, Such as figure 2 shown;

[0025] 2) The fatigue life of the roof-longitudinal rib welding detail 4 is affected by the stress in the transverse bridge direction of the roof. For this reason, a strain sensor 6 is installed on the roof 2 at the welding detail where fatigue cracking occurs (such as figure 2 shown), obtain the cross-bridge direction strain data of one month t (t=30) days;

[0026] 3) Taking 1 day as the calculation interval, use the rainflow counting method (a widely used fatigue stress data analysis metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com