UV (ultraviolet) solidified bonding magnet and preparation method thereof

A technology of bonding magnets and curing resins, applied to magnetic objects, magnetic materials, permanent magnets, etc., can solve problems such as physical health damage and environmental pollution of operators, and achieve the effects of cheap equipment, good treatment effect and little environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

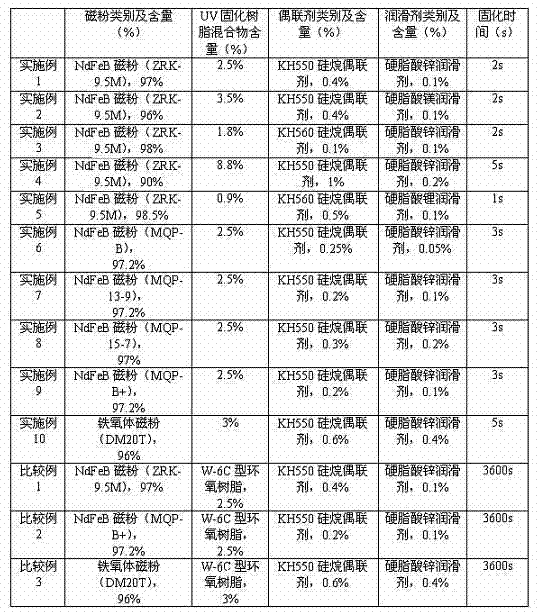

[0063] A UV curable bonded magnet, its raw material formula includes: 97% domestic bonded NdFeB magnetic powder (brand ZRK-9.5M); 2.5% UV curable resin mixture; 0.4% KH550 silane coupling agent; 0.1% zinc stearate lubricant.

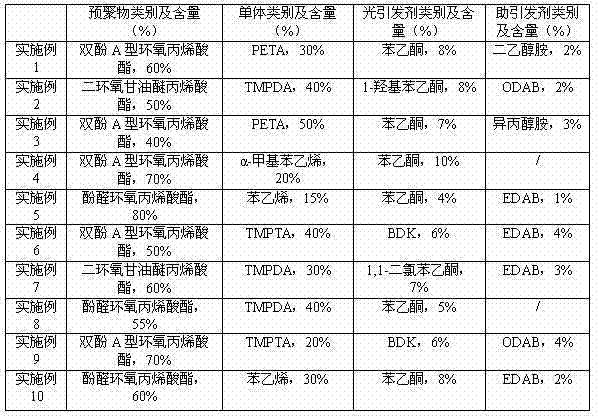

[0064] The above-mentioned UV curable resin mixture comprises by weight percentage: 60% bisphenol A type epoxy acrylate prepolymer; 30% PETA monomer that can be polymerized with the above-mentioned prepolymer component; 8% acetophenone Photoinitiator; 2% diethanolamine co-initiator.

[0065] Prepare as follows:

[0066] (1) Add the domestic bonded NdFeB magnetic powder into the ethanol solution of KH550 silane coupling agent, let it stand for a period of time until it evaporates to dryness, and bake it in an oven at 70°C for 1 hour;

[0067] (2) The above-mentioned magnetic powder and UV curable resin mixture are mixed in acetone solvent, then dried and granulated to make a mixed magnetic powder;

[0068] (3) The mixed rubber magnetic powder is matche...

Embodiment 2~ Embodiment 10

[0073] The method for preparing UV-cured bonded magnets in Examples 2 to 10 is the same as in Example 1, except that the UV-cured bonded magnet raw material components and the composition of the UV-cured resin mixture are different. The detailed components are shown in Table 1 and Table 2 shows.

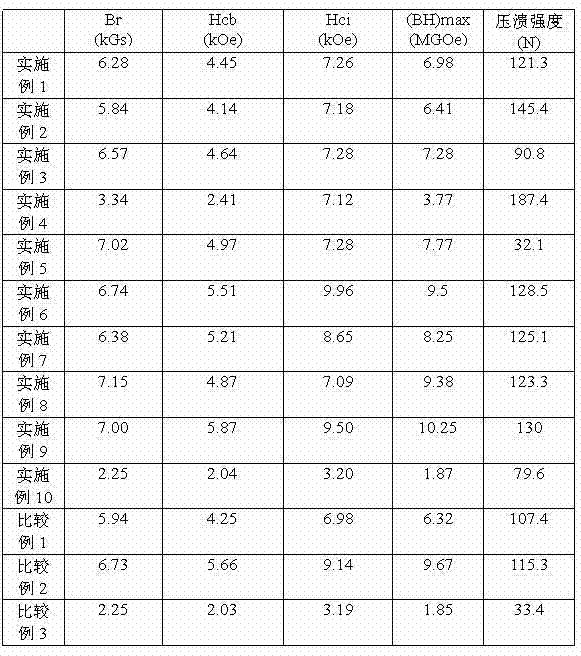

[0074] The performance results of the bonded magnets, such as magnetic properties and crush strength, are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com