Test method for simulating working mechanism of drilling rig for gas drilling

A technology of gas drilling and test method, which is applied in the direction of testing wear resistance, testing machinability, etc., which can solve the problem of inability to test the fatigue life of drilling tools, restrict the large-scale application of gas drilling technology, and simulate the erosion and wear of drilling tools at the same time and other problems, to achieve the effect of quick start, light weight and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The concrete implementation steps of the present invention are described below in conjunction with accompanying drawing:

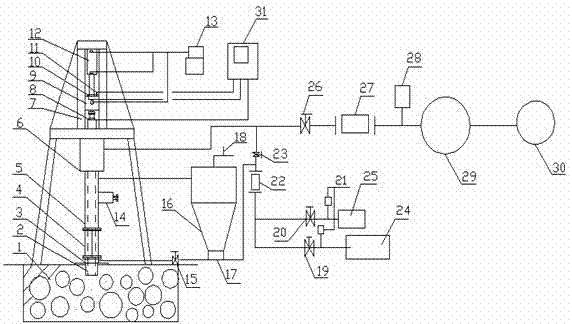

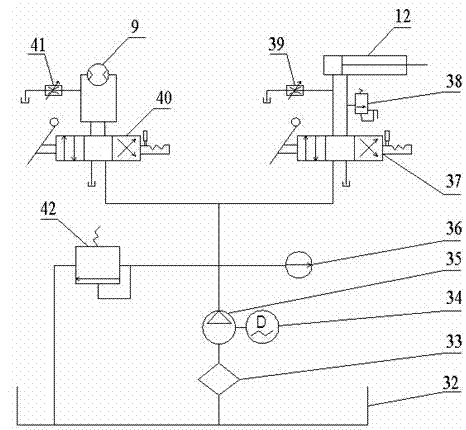

[0016] Such as figure 1 , figure 2 , image 3 As shown, the present invention is a kind of test method for simulating the working mechanism of gas drilling tools, including gas drilling tools erosion wear test method, gas drilling tool stress test method and gas drilling tool fatigue fracture test method.

[0017] The gas drilling drilling tool erosion wear test method adopts the following steps: ① before the test, the test derrick 7 is fixed on the cement foundation 1, and the weight of the drilling tool 2 in the test section before the test is weighed; ② the large fan 24 is turned on, and the small fan 25 and air compressor 29, through the pressure transmitter 21, flow sensor 22, pressure transmitter 28, and flow transmitter 27 to control the air pressure and air volume required for the test, and record the time when the fan is turned on at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com