Multi-axial fatigue fracture test equipment for bridge expansion joint material and implementation method of multi-axial fatigue fracture test equipment

An expansion joint material, fatigue failure technology, applied in the direction of using a stable bending force to test the material strength, using a stable tension/pressure test to test the material strength, etc., can solve the problem that the fatigue life and the actual fatigue life curve cannot be well overlapped , can not guide design production, deviation and other issues well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

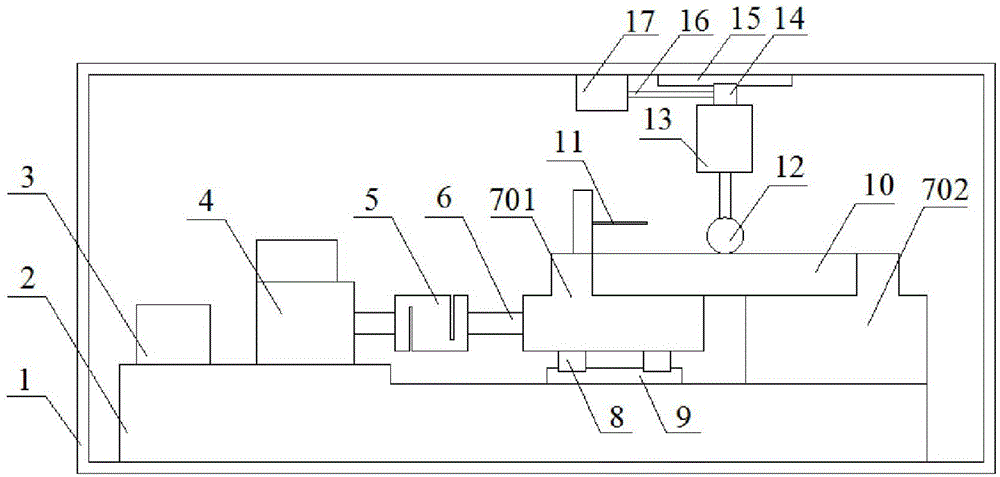

[0016] see figure 1 , the present invention provides a bridge expansion joint material multiaxial fatigue failure test equipment, including an outer frame 1, a base 2, a computer 3, an electric cylinder 4, a pressure sensor 5, a transmission shaft 6, a mobile concrete member 701, a fixed concrete member 702, Slider A8, base guide rail 9, expansion joint material 10, temperature sensor 11, solid rubber ball 12, pneumatic booster 13, slider B14, top guide rail 15, lead screw 16, motor 17; electric cylinder 4 is placed on the base The two ends of the transmission shaft 6 are respectively connected with the pressure sensor 5 and the mobile concrete member 701. The electric cylinder 4, the pressure sensor 5 and the transmission shaft 6 constitute the transmission device; the base rail 9 is fixed on the base 2, The slider A8 is fixedly connected with the mobile concrete member 701, and placed on the base guide rail 9 to realize the horizontal movement of the mobile concrete member;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com