Heavy-duty car frame bending torsion fatigue test bench device and method thereof

A fatigue test, heavy-duty vehicle technology, applied in the direction of measuring device, vehicle test, mechanical parts test, etc., can solve the problems of inability to simulate dynamic load state, increase test cost, high price of hydraulic loading device, etc., to achieve vertical The effect of uniform load distribution and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

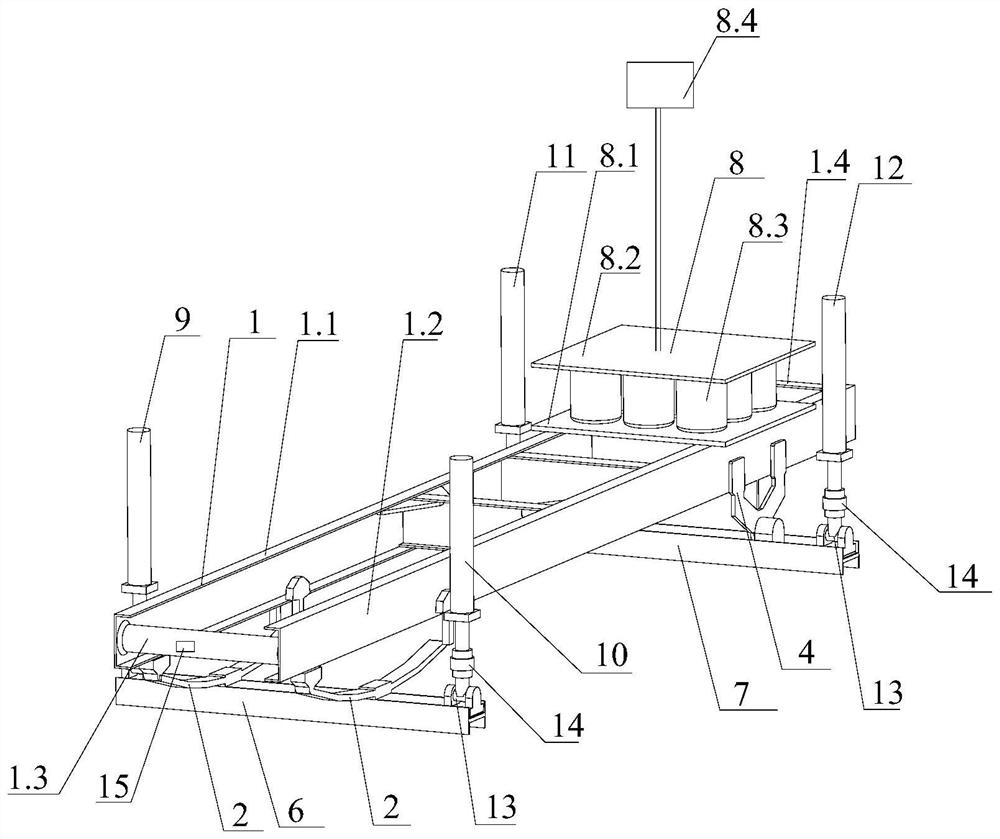

[0025] combine figure 1 As shown, the heavy-duty vehicle frame bending-torsion fatigue test bench device designed for the frame structure of the tractor includes a frame assembly 1, a front suspension assembly 2, a rear suspension assembly 4, a front axle 6, and a rear axle 7. A set of airbag loading unit 8, first torsion cylinder 9, second torsion cylinder 10, third torsion cylinder 11, fourth torsion cylinder 12, four ball joints 13, four force sensors 14, two angle sensors 15 ;

[0026] Vehicle frame assembly 1 comprises left longitudinal beam 1.1, right longitudinal beam 1.2, front end cross beam 1.3 and rear end cross beam 1.4, angle sensor 15 is installed on front end cross beam 1.3 and rear end cross beam 1.4, front suspension assembly 2 is installed on vehicle frame assembly As the front end of 1, the rear suspension assembly 4 is installed at the rear end of the vehicle frame assembly 1, the middle part of the front axle 6 is connected with the front suspension asse...

Embodiment 2

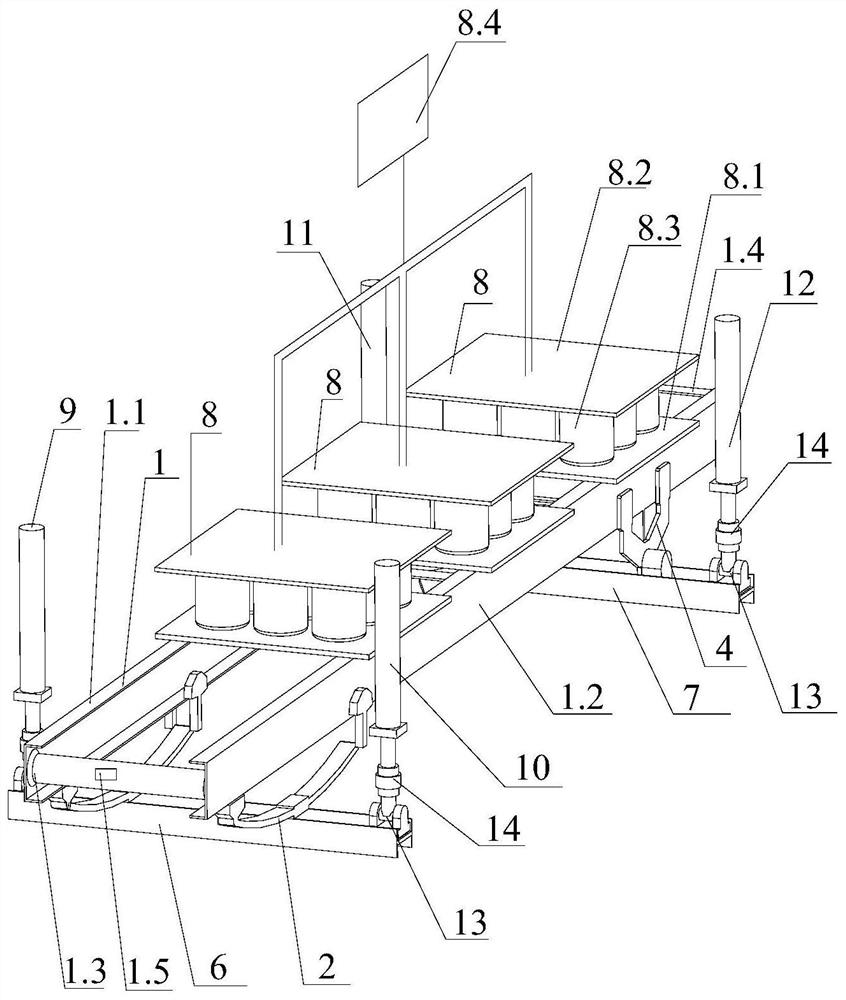

[0038] to combine figure 2 As shown, for the heavy-duty vehicle frame bending-torsion fatigue test bench device designed for the frame structure of the truck, since the load position and size of the truck are different from those of the tractor, the heavy-duty vehicle frame of embodiment 2 is bent Compared with the embodiment, the torsional fatigue test bench device has only done the adjustment of the airbag loading unit 8, such as figure 2 As shown, there are three sets of airbag loading units 8 in this embodiment along the length direction of the cargo area of the vehicle frame. The structure of each set of airbag loading units 8 is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com