Torque measurement apparatus and method for miniature tension-torsion fatigue testing machine

A fatigue testing machine and torque measurement technology, used in measuring devices, force/torque/work measuring instruments, and testing the strength of materials by applying a stable torsion force. Fatigue testing machines and high-precision torque sensors are difficult to use in micron-meter-level test torque measurement, and cannot meet measurement error requirements, so as to prevent axial overload damage, high accuracy, and axial overload protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

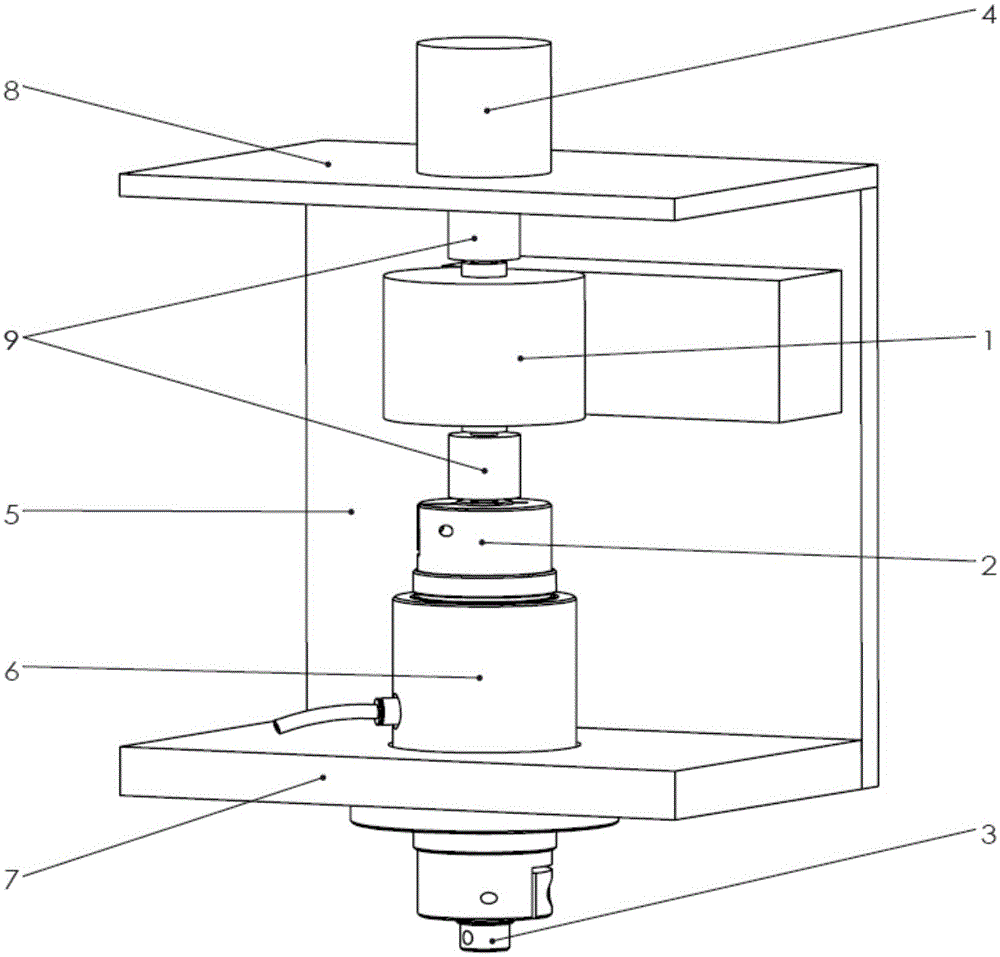

[0023] Such as figure 1 As shown in the figure, a torque measurement device for a miniature tension and torsion fatigue testing machine is applied in the torque measurement actuation unit, mainly including a high-precision dynamic torque sensor Interface T11 (1), which is installed on the high-precision torque sensor to measure the air at the end of the shaft. Thrust bearing OAVTB32i13 (2), bearing main shaft (3), DC motor (4) installed on the drive shaft end of the torque sensor to provide torsional action, and respectively connected to the motor output shaft-torque sensor drive shaft and torque sensor measurement shaft-bearing Single-segment slit-type flexible coupling (9) for the main shaft.

[0024] The torque sensor (1) is fixed on the torque sensor fixing plate (5) by side screws. The outer periphery of the air thrust bearing (2) is fixed to the single-side flange sleeve type bearing fixing part (6) through an O-ring or glue, and the bearing fixing part (6) is fastened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com