Reciprocating torsion durability test device and test method

A testing device, a durable technology, applied in the direction of measuring device, using repeated force/pulsation force to test the strength of materials, instruments, etc., can solve the problem that product defects cannot be detected, and achieve the elimination of invalid external force interference, stable spindle speed, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

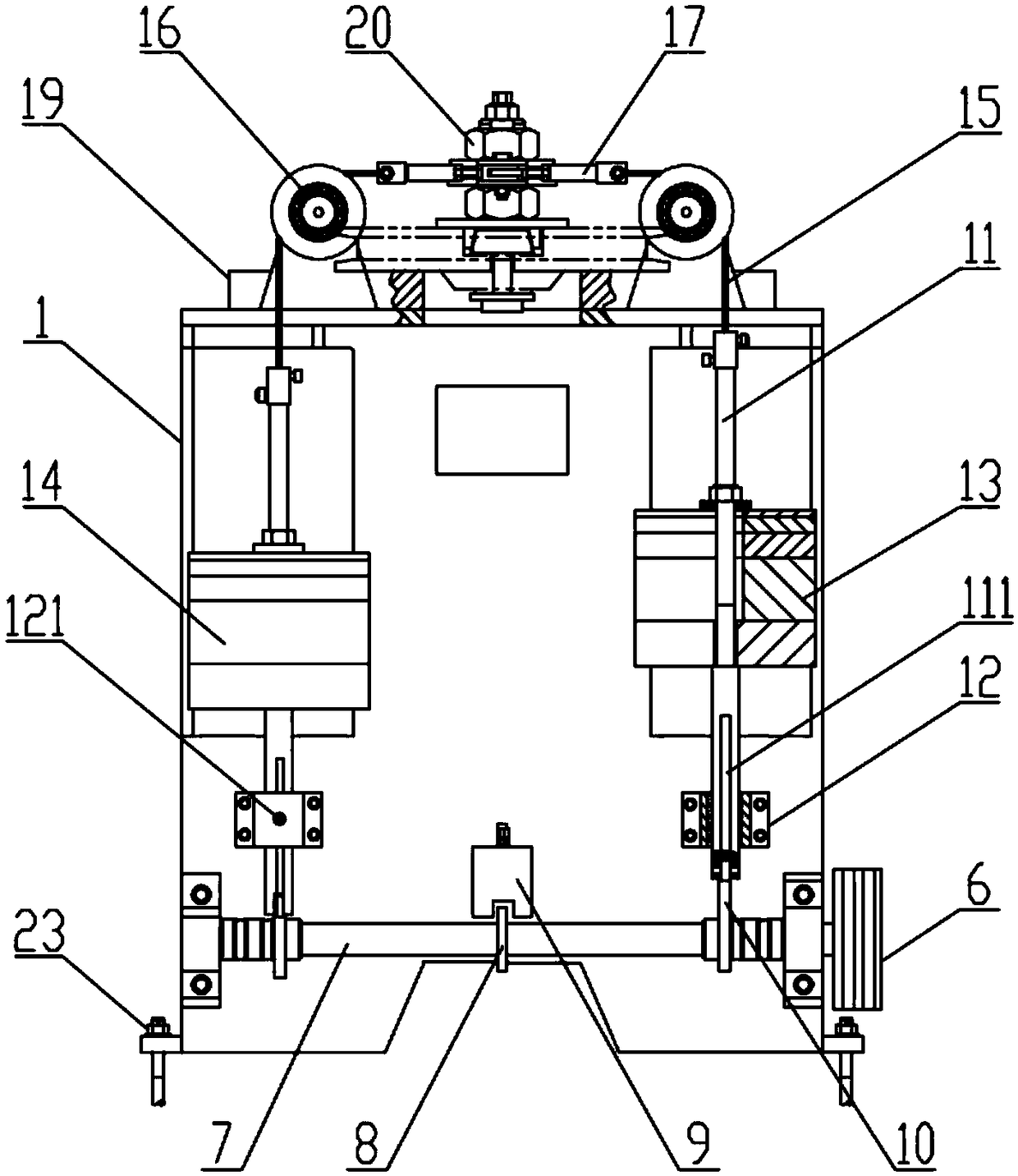

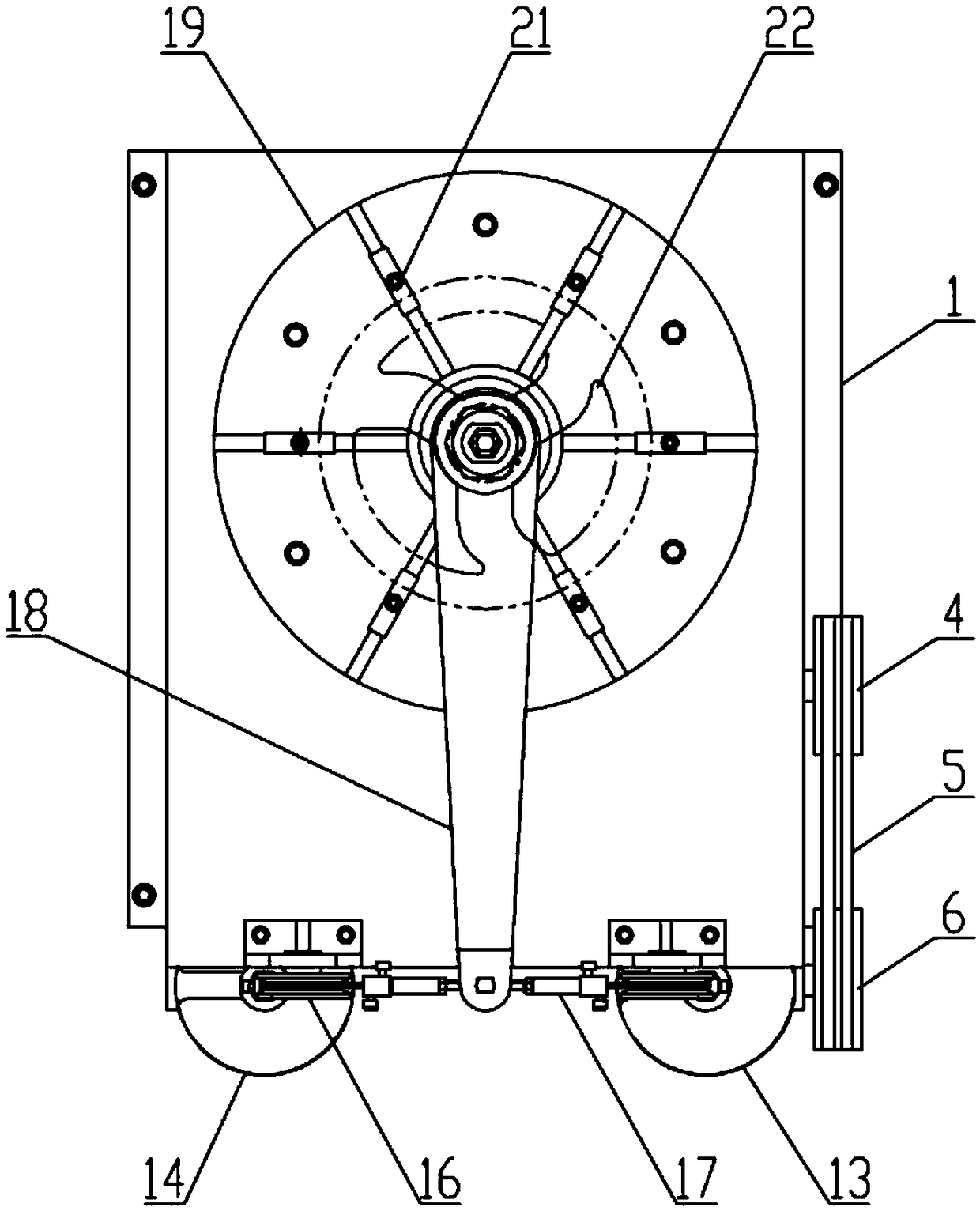

[0052] A reciprocating torsion durability test device, such as figure 1 , 2 , 3, including a box body 1, the box body 1 is fixed on the workbench or the ground by anchor screws 23, and also includes a fixed table 19, a tensioning mechanism 20, a swing rod 18, a pulley mechanism 16, and a falling device , a cam mechanism and a power unit, the fixed table 19 is arranged on the top of the box body 1 for fixing the workpiece 22 to be measured; One end is inserted into the shaft hole of the core of the workpiece 22 to be tested and tightened, and the other end is vertically connected to the swing rod 18; the pulley mechanism 16 is symmetrically arranged on the top of the front side of the box body 1; The upper end of the falling device is connected by a flexible rope 15, and the flexible rope 15 is wound on the pulley mechanism 16, and the falling device falls under gravity to tighten the flexible rope 15; The mechanism 20 is fixedly connected, and the other end is fixedly connec...

Embodiment 2

[0064] A kind of to-and-fro torsional endurance testing device of the present embodiment, the basic structure is the same as that of embodiment 1, the differences and improvements are as follows: figure 1 , 2 As shown, the falling device includes a connecting rod 11, a guide sleeve 12 and a gravity weight, the gravity weight is detachably connected to the connecting rod 11, and the guide sleeve 12 is fixed on the front of the box body 1. side, and slide on the connecting rod 11, so that the connecting rod 11 can slide up and down along the guide sleeve 12; in this embodiment, the gravity weight is sleeved on the connecting rod 11, And fixed by nuts, it is convenient to disassemble and replace the gravity weight, and then adjust the test torque; it can be understood that the gravity weight and the connecting rod 11 can also be connected in other detachable ways.

[0065] Such as figure 1 As shown, the cam mechanism includes a driven wheel 6, a main shaft 7 and two cams 10, th...

Embodiment 3

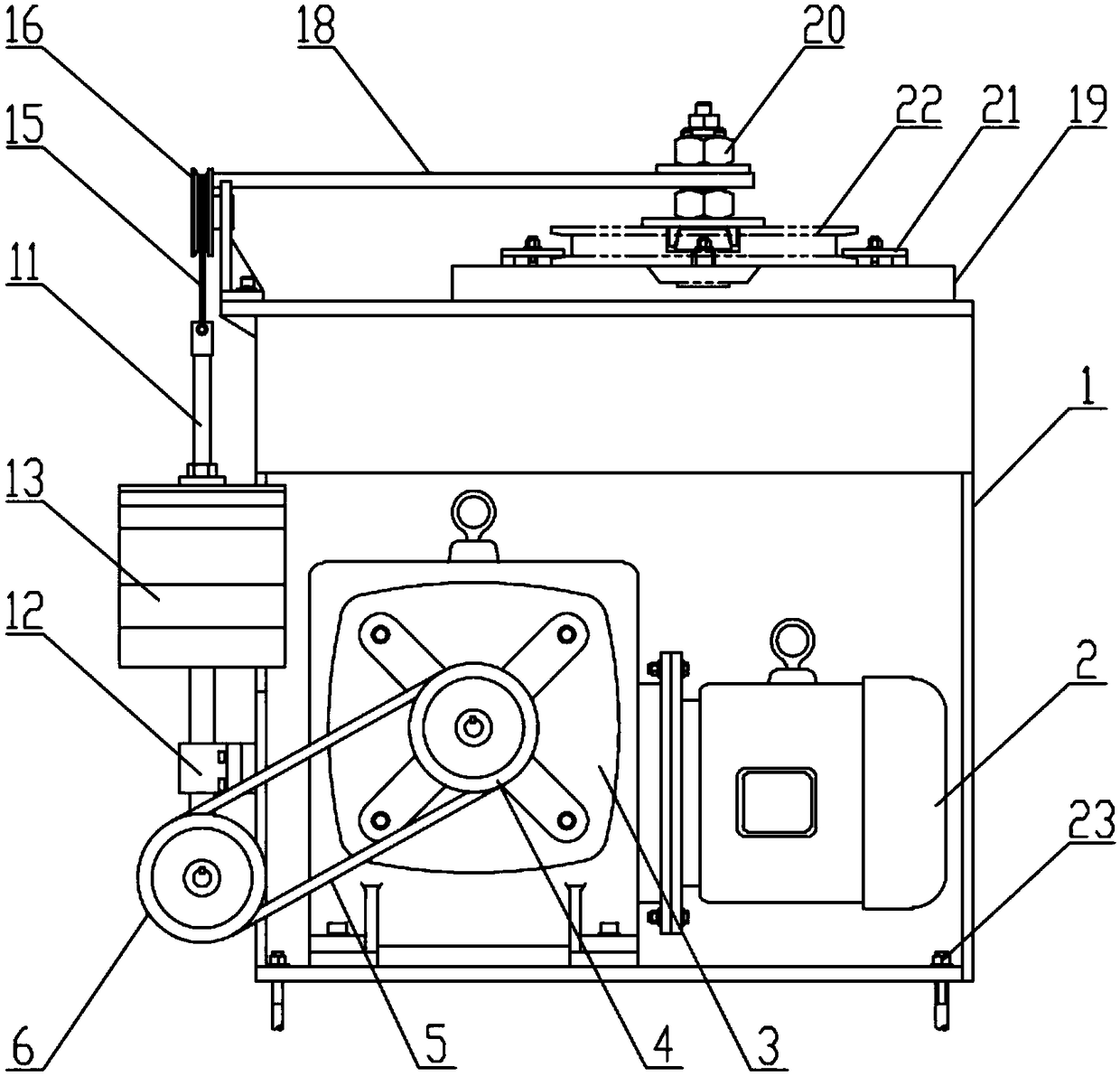

[0070] A kind of to-and-fro torsion durability testing device of the present embodiment, the basic structure is the same as embodiment 2, the differences and improvements are as follows: figure 2 As shown, the power device includes a motor 2 , a transmission 3 , and a driving wheel 4 that are matched and connected in sequence, and the driving wheel 4 is connected to the driven wheel 6 through a transmission belt 5 . During operation, after the motor 2 is started, the rotating speed is too fast, and after being decelerated by the transmission 3, it is output by the driving wheel 4, and then transmitted to the driven wheel 6 through the transmission belt 5. In this embodiment, the motor 2 is a steplessly variable speed motor with an adjustable speed, thereby being able to adjust the alternating speed of the torsional force, so as to save the detection time to the greatest extent and improve the detection efficiency while meeting the test requirements.

[0071] In the reciprocat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com