Rubber diaphragm antifatigue test device

A testing device and rubber diaphragm technology, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc. problems, to achieve the effect of high test efficiency, smooth reciprocating operation, and reduced impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

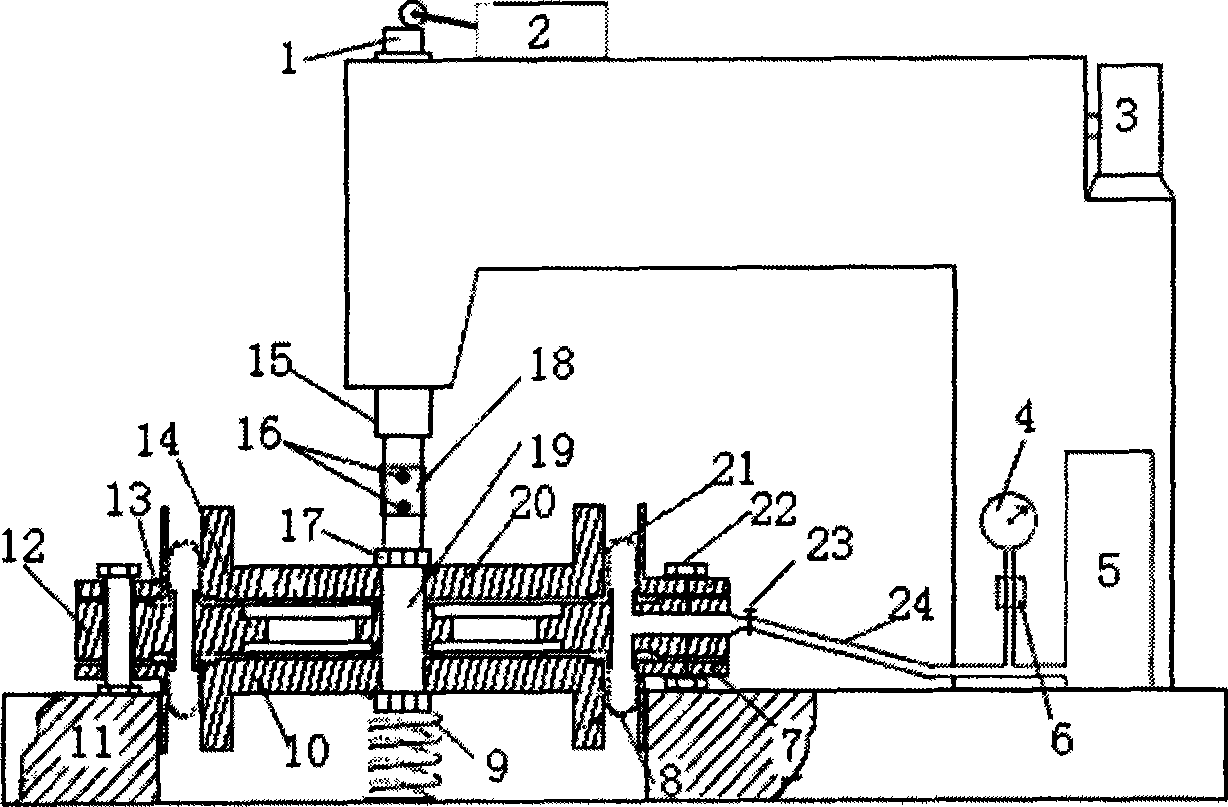

[0021] Embodiment 1: A test device suitable for a DN25 balance diaphragm.

[0022] Motor 3 is a mechanical clutch motor, voltage: 380V three-phase; current: 0.9A; power: 370W; speed: 2850r / min; counter 2 is a mechanical counter; air pump 5 is a manual air compressor.

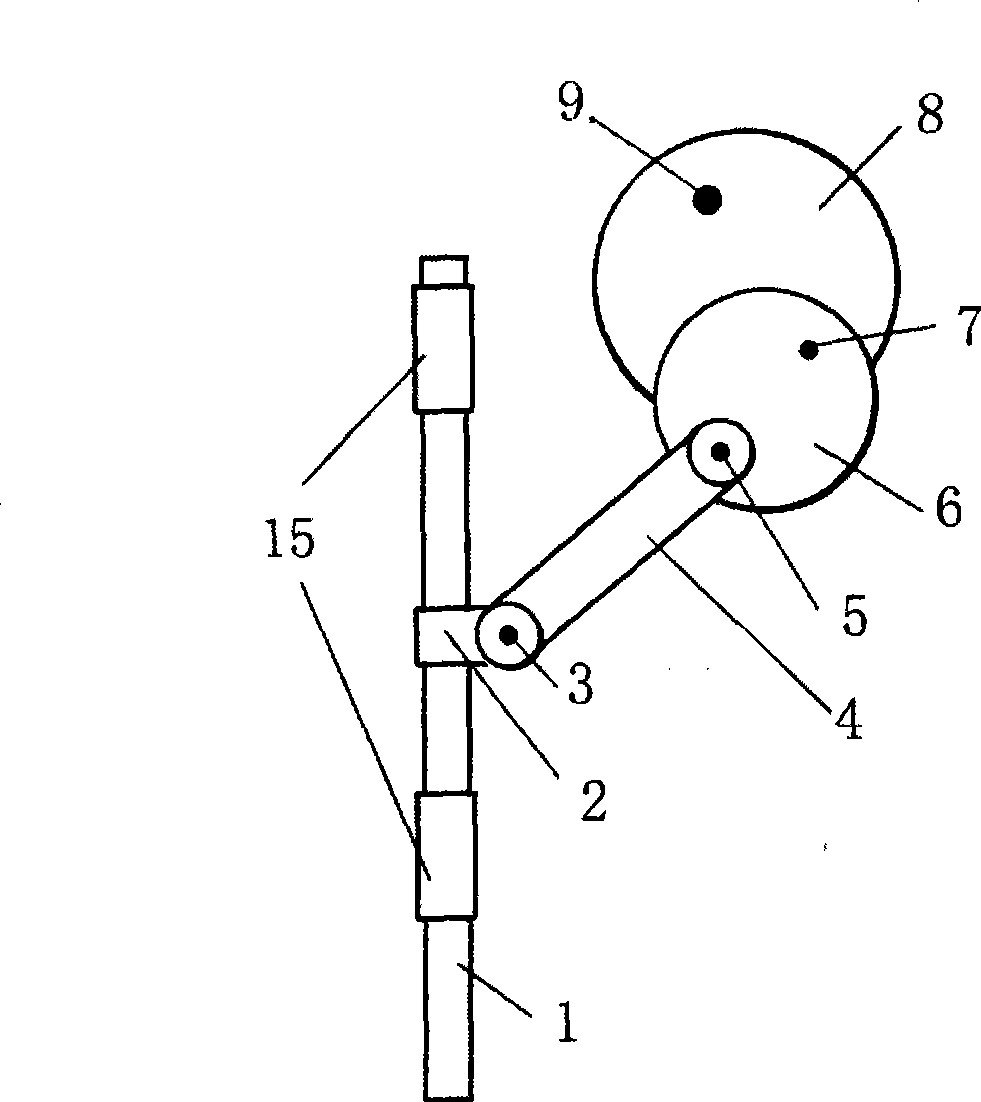

[0023] Two eccentric wheels are designed in the device of this embodiment, and the size of the stroke needs to be adjusted according to the shape of the diaphragm and the actual stroke. For adjustment needs, once the stroke is determined, the secondary eccentric wheel and the primary eccentric shaft are fixed with screws. The primary eccentricity is 50mm, the secondary eccentricity is 46mm, and the adjustment range of the total eccentricity is generally 4-96mm. The reciprocating stroke is twice the total eccentricity.

[0024] The working stroke of the diaphragm DN25 is 18mm, and the set air pressure is 0.4Mpa. After adjusting the total eccentricity of the primary and secondary eccentric wheels to 9mm, tighten ...

Embodiment 2

[0026] Embodiment 2: A test device suitable for the main adjustment diaphragm of a NORVAL / G DVGW voltage regulator.

[0027] The motor is a DC variable frequency speed regulating motor, voltage: 380V three-phase; current: 1A; power: 300W; speed: 1750r / min; the counter is a photoelectric counter; the air pump is an electric air compressor.

[0028] Two eccentric wheels are designed in the device of this embodiment, and the size of the stroke needs to be adjusted according to the shape of the diaphragm and the actual stroke. For adjustment needs, once the stroke is determined, the secondary eccentric wheel and the primary eccentric shaft are fixed with screws. The primary eccentricity is 50mm, the secondary eccentricity is 46mm, and the adjustment range of the total eccentricity is generally 4-96mm. The reciprocating stroke is twice the total eccentricity.

[0029] The diameter of the diaphragm is 630mm, the reciprocating stroke is 80mm, the air pressure is 0.12Mpa, adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com