Dynamic torsional fatigue mechanical property test device in tensile preload

A torsional fatigue and testing device technology, applied in measuring devices, using stable tension/pressure to test material strength, scientific instruments, etc., can solve problems such as difficulty in ensuring the reliability of components, and achieve strong practical value, simple structure, easy to use. effect achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

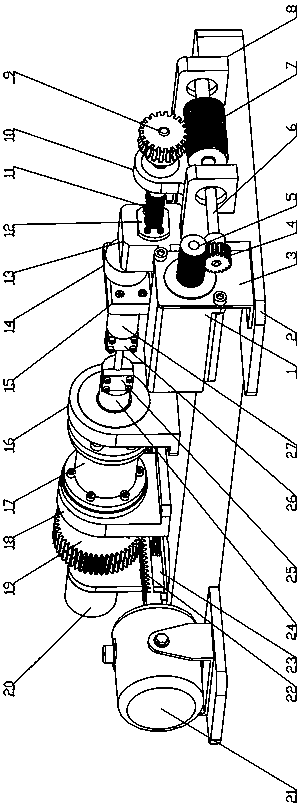

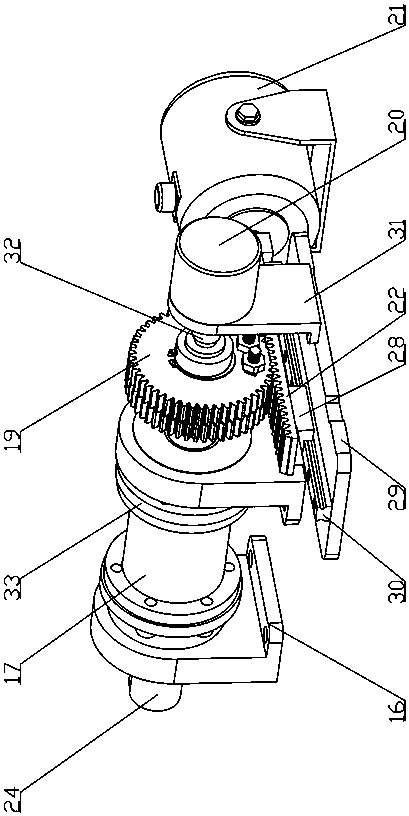

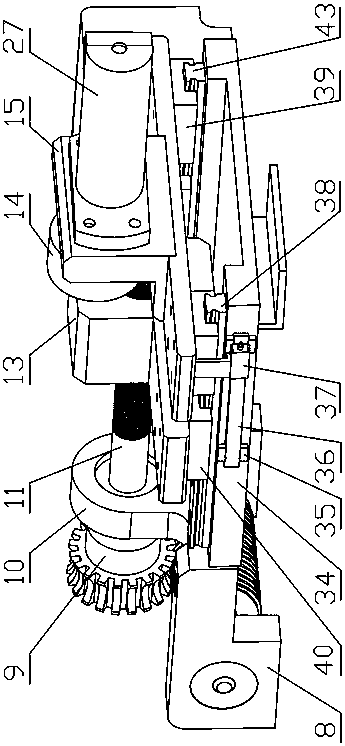

[0021] see Figure 1 to Figure 5 As shown, the test device for dynamic torsional fatigue mechanical properties under tensile preload of the present invention adopts a horizontal arrangement, including a tension unit, a torsional fatigue unit, a force signal and displacement signal detection unit, and a specimen clamping unit. The tension unit and the torsional fatigue unit are respectively arranged on both sides of the specimen 42, and are on the same axis as the specimen 42; the tension unit, the torsional fatigue unit, the force signal and displacement signal detection unit and the specimen holding unit are all installed On the bottom plate 2; a large space is reserved in the central area of the device, and the magnetic field and thermal field loading can be placed between the tensile unit and the torsional fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com