Air spring torsion fatigue test method and device for track traffic

An air spring, rail transit technology, applied in measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problem of not being able to fully and truly simulate the actual force and deformation state of air springs, and the accuracy of test results. Low problems, to achieve the effect of easy maintenance, stable operation and simple control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

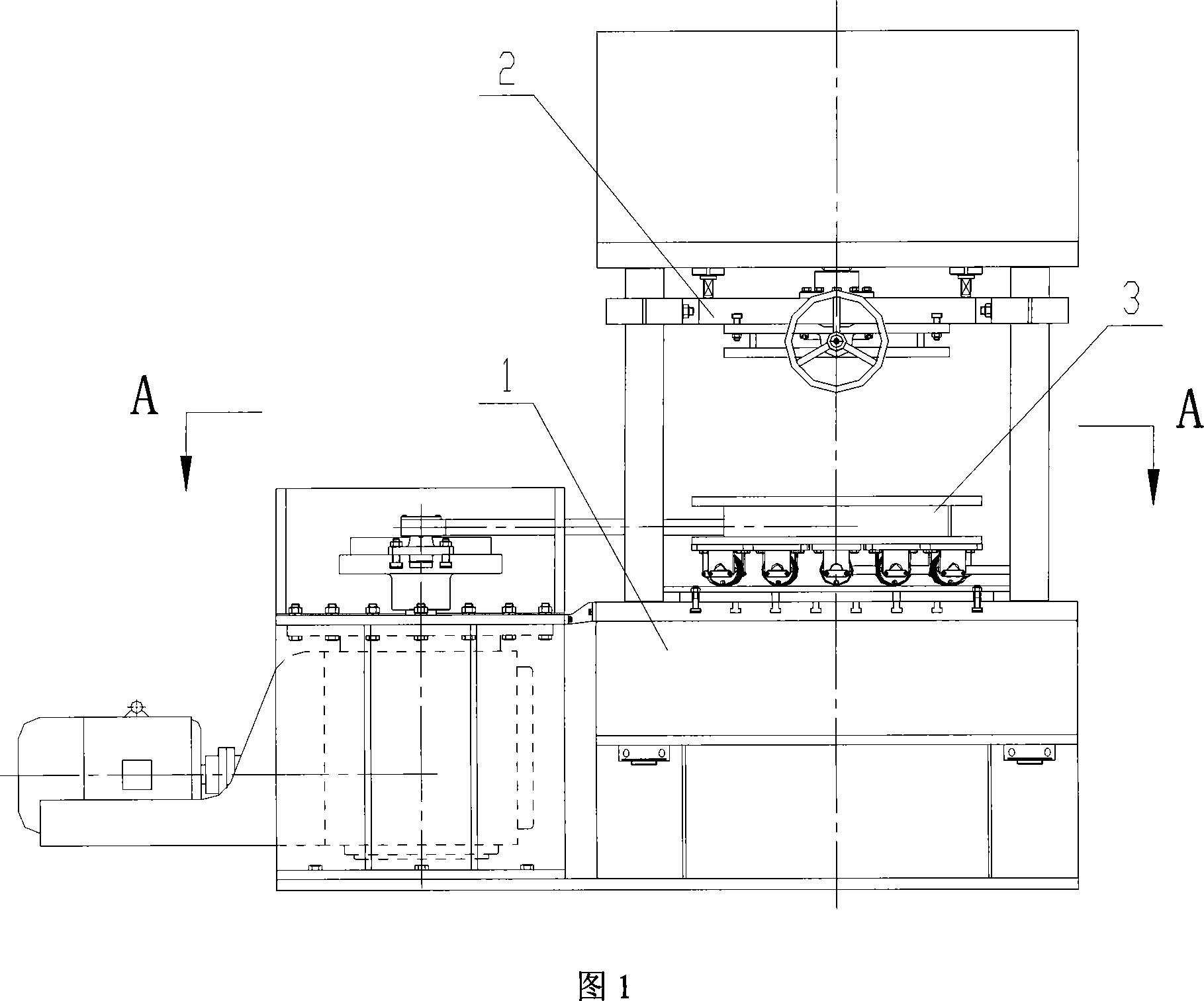

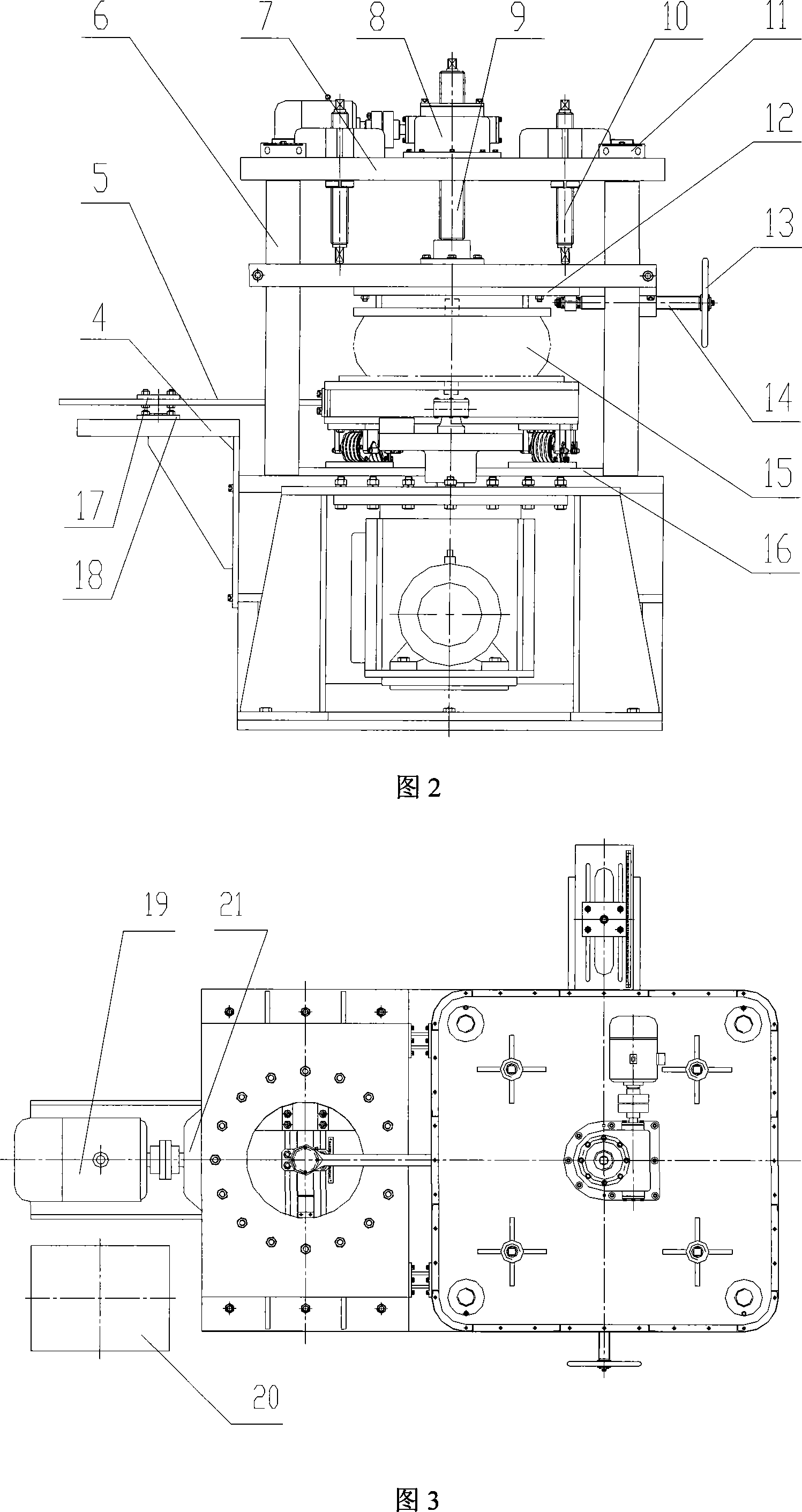

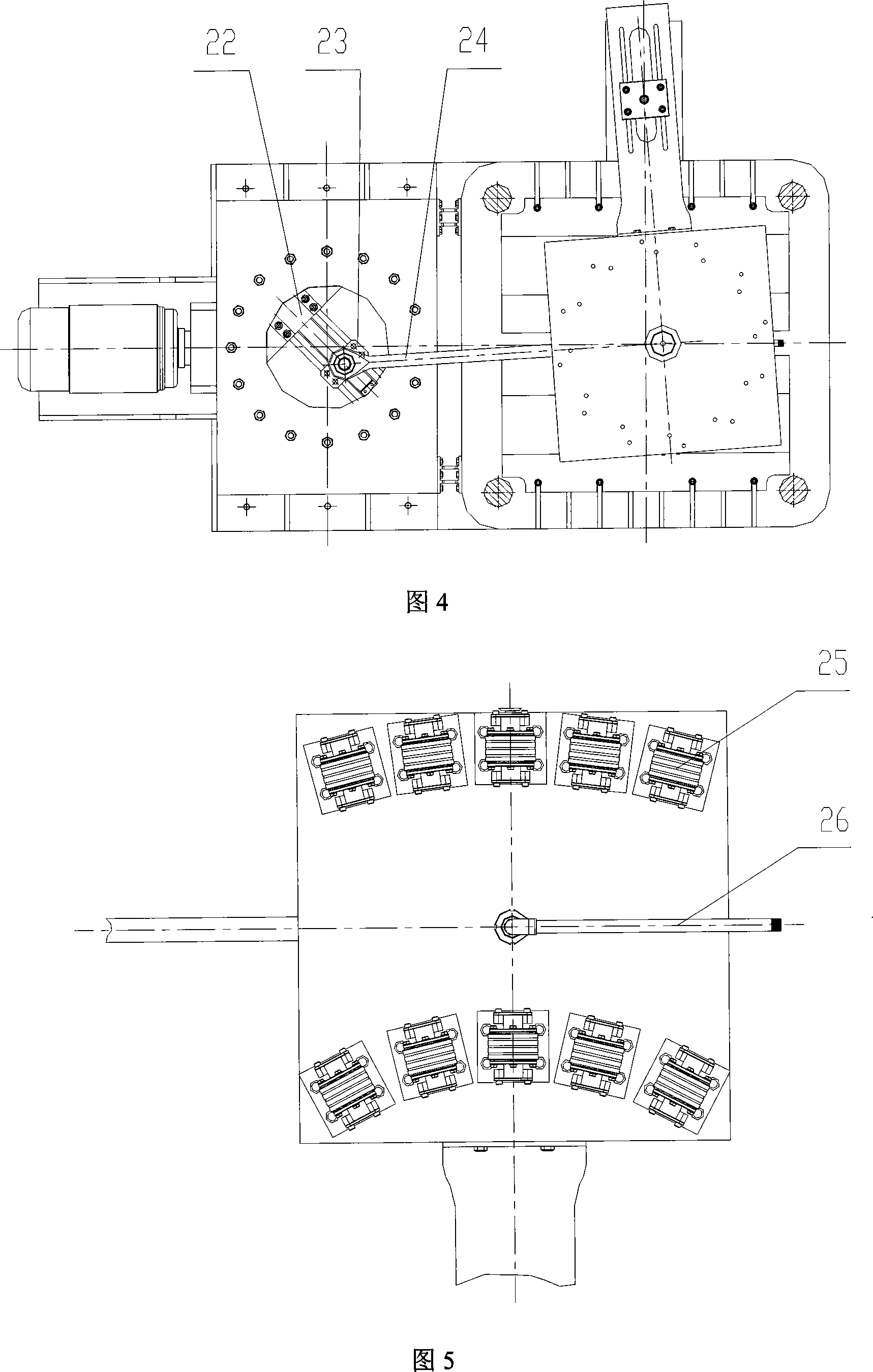

[0015] As can be seen from the accompanying drawings, the present invention is an air spring torsion fatigue test device for rail transit. The test method of this device is to simulate the torsion of the actual working state of the air spring through a vertical, lateral and torsional multi-dimensional loading system. stress test. The vertical, transverse and torsional multi-dimensional loading system includes at least one set of vertical loading system, one set of lateral loading system and one set of torsional loading system. The air spring is loaded vertically by the vertical loading system, the air spring is loaded laterally by the lateral loading system, and the torsional loading system is used torsionally load the air spring, and combined to form a multi-dimensional composite of vertical, lateral, and arc swings for the air spring Functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com