Torsion device used for large horizontal tail shaft torsion fatigue test

A technology of horizontal tail shaft and power device, applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problem of narrow selectivity and achieve the effect of low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

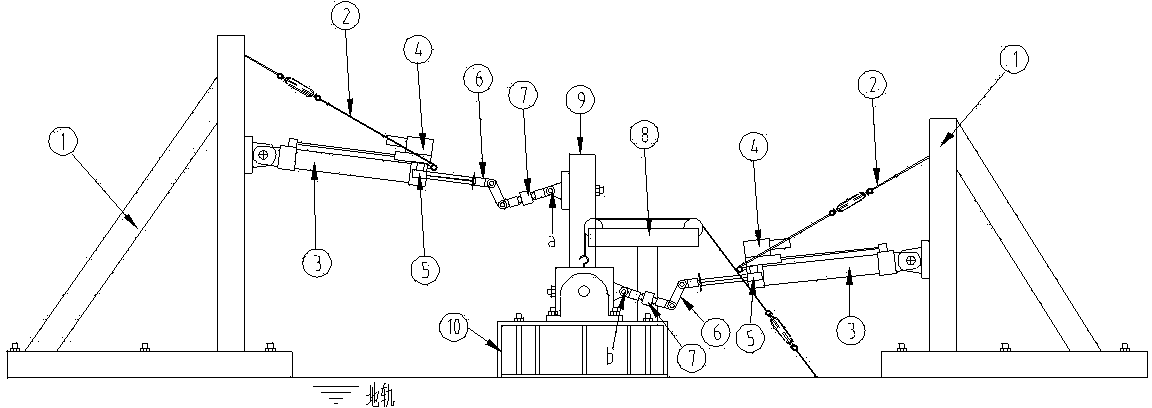

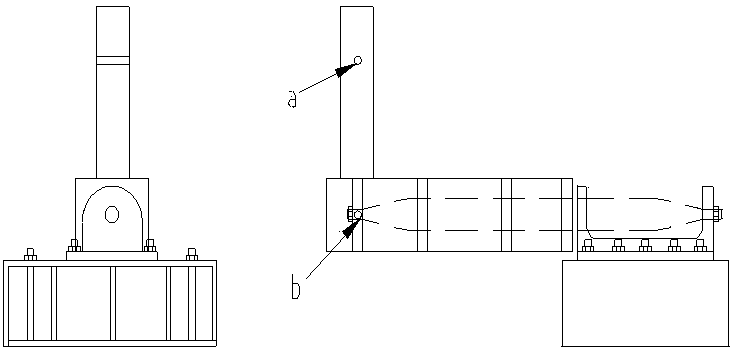

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the present invention is mainly made up of power unit, mechanical transmission device and control system. The power unit is a hydraulic system, which is composed of a hydraulic pump station and pipelines, and the working pressure is selected as 17MPa. The control system is a two-channel coordinated loading system, and the loading waveform is a triangular wave. The mechanical transmission device consists of a load-bearing column (1), a steel wire rope (2), a hydraulic cylinder (3), a servo valve (4), a displacement sensor (5), a connecting rod device (6), a force sensor (7), and a load-bearing device ( 8), test piece fixing device (9), and base (10).

[0013] According to the requirements of the test program, the angle of the hydraulic cylinder (3) is adjusted through the steel wire rope (2). After adjustment, the connecting rod devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com