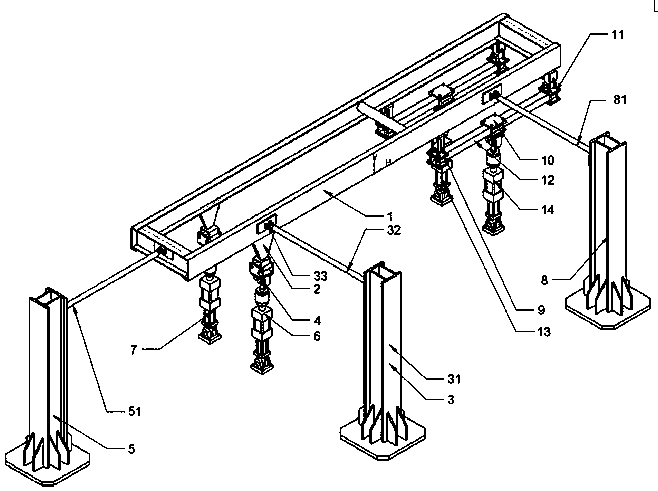

Vehicle frame assembly torsion fatigue loading test stand and test method

A torsional fatigue and loading test technology, which is applied in vehicle suspension/shock absorbing mechanism testing, mechanical component testing, machine/structural component testing, etc., can solve inaccurate torsional performance testing and inaccurate road load relationship of vehicle frame assembly Clarify issues such as frame freedom and over-constraints to improve the significance of the test and facilitate lightweight verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

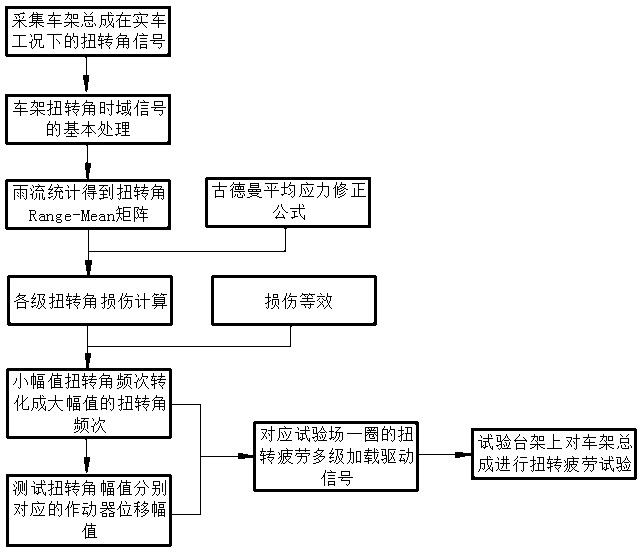

Method used

Image

Examples

Embodiment 1

[0059] The following is an example of converting the torsion signal of the 1# commercial vehicle frame into a load spectrum.

[0060] 1. Rainflow Statistics

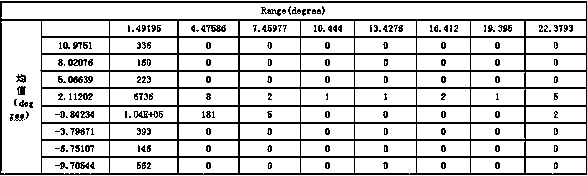

[0061] The frame torsion angle signal is counted, Range is divided into 8 levels, and the 1# commercial vehicle characteristic 3-way frame torsion angle matrix statistics are shown in the following table:

[0062] Table 1. Statistical table of torsion angle of 1# commercial vehicle characteristics 3-way frame

[0063]

[0064] 2. Use the Miner fatigue cumulative damage theory to calculate the relative damage of the above rainflow matrix, and use the Goodman (Goodman) average stress correction formula to correct the damage corresponding to each level of load.

[0065] Miner fatigue cumulative damage theory formula is as follows:

[0066]

[0067] In the above formula, D is the total damage, is the i-th degree of damage, is the actual number of cycles under the i-th stress level, is the life under the i-th ...

Embodiment 2

[0080] The following is an example of converting the torsion signal of the 2# commercial vehicle frame into a load spectrum.

[0081] 1. Rainflow Statistics

[0082] Table 1. Statistical table of torsion angle of 2# commercial vehicle characteristics 3-way frame

[0083]

[0084] 2. Use the above rainflow matrix to calculate relative damage, and use Goodman's average stress correction formula to correct the damage corresponding to all levels of load.

[0085] Table 2. Statistical table of relative damage after 3-way correction of 2# commercial vehicle characteristics

[0086]

[0087] 3. Relative damage equivalent control test cycle times

[0088] Table 3. 2# commercial vehicle characteristic 3-way 4-level torsion angle amplitude and cycle count statistical table

[0089]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com