Device and method for testing tension and torsion coupling performance of flexible tube cable structure

A duct cable and flexible technology, which is applied in the field of testing and testing devices under the coupling conditions of tension and torsion, can solve the problems of prone to errors, complicated testing operations, and lack of ideal testing solutions and testing equipment. Convenience, coupled effects with precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

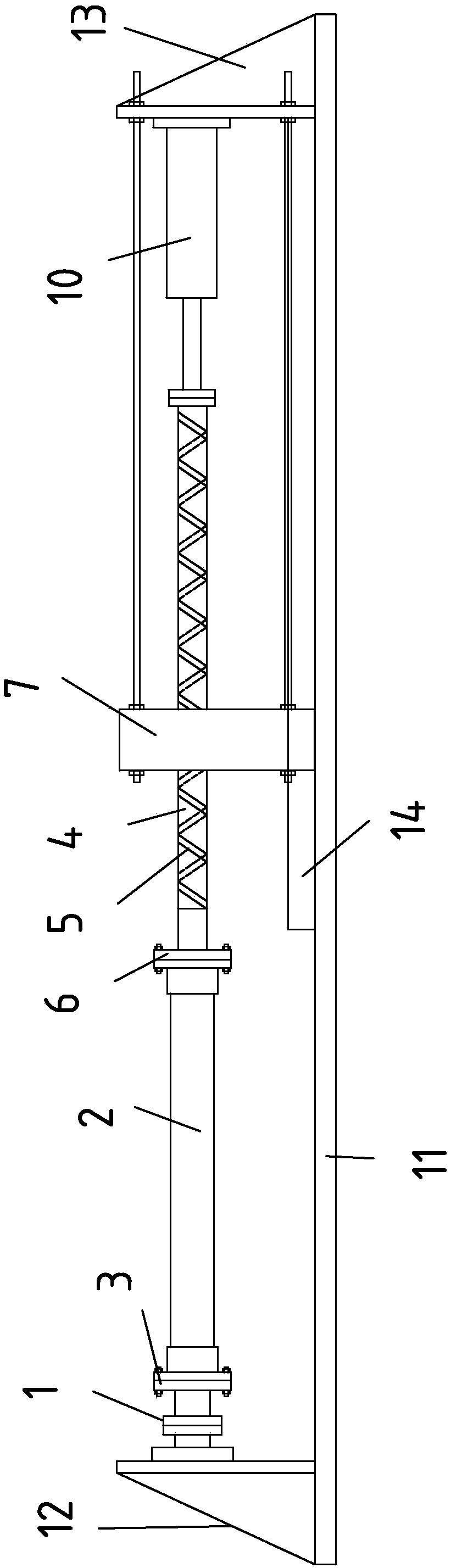

[0027] Such as Figure 1-Figure 3 As shown, a device for testing the tensile and torsion coupling performance of a flexible umbilical cable structure includes:

[0028] Torque limiter 1, one end of which is fixed, and the other end is provided with a first umbilical joint 3 for connecting one end of flexible umbilical cable 2;

[0029] The twisted screw rod 4 has a spiral protrusion 5 on its outer wall, and one end thereof is provided with a second umbilical joint 6 for connecting the other end of the flexible umbilical cable 2;

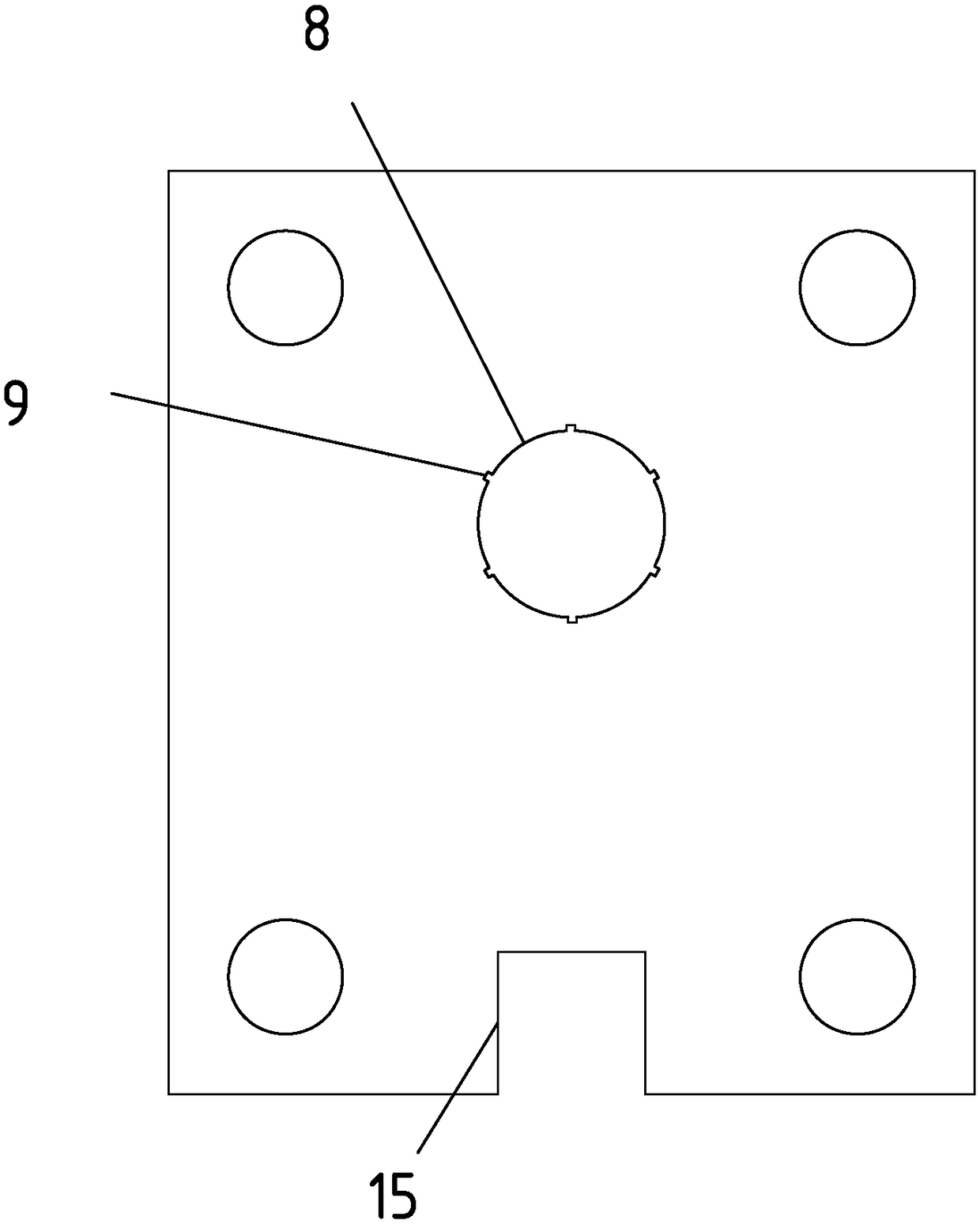

[0030] The spiral baffle 7 has a through hole 8 through which the twisted screw rod 4 passes, and the through hole 8 is provided with a spiral groove 9 engaged with the spiral protrusion 5;

[0031] And a tension actuator 10 for driving the twisted screw rod 4 to screw feed relative to the through hole 8 .

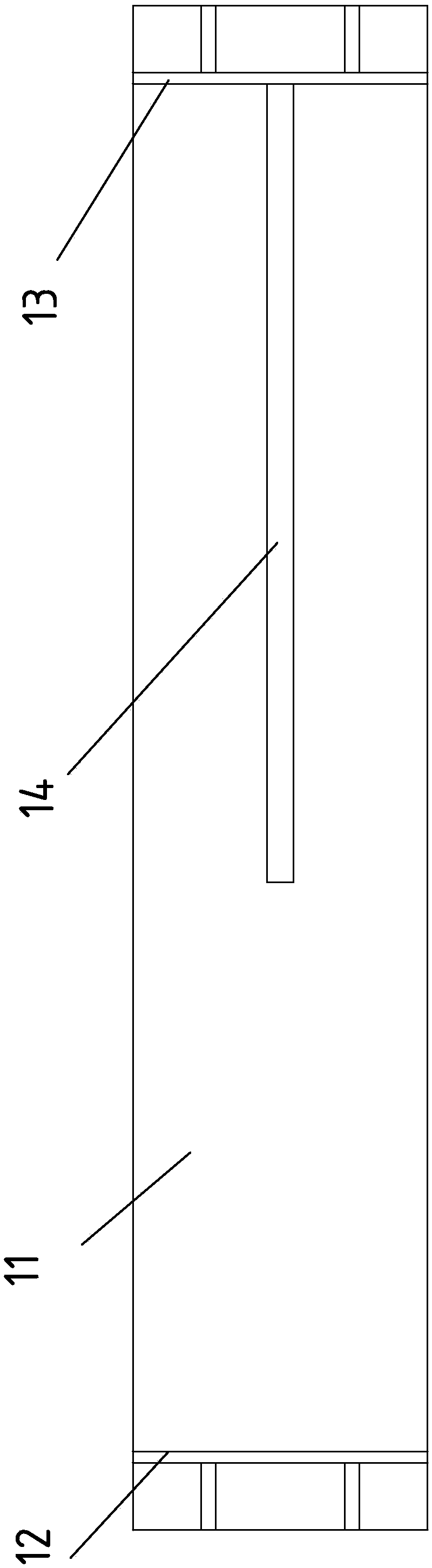

[0032] Also includes a base 11, the two ends of the base 11 are respectively provided with a first triangle reaction frame 12 and a second tri...

Embodiment 2

[0034] A method for testing the tensile and torsion coupling performance of a flexible umbilical cable structure using the device for testing the tensile torsion coupling performance of a flexible umbilical cable structure described in Example 1. The two ends of the flexible umbilical cable sample cable 2 are respectively connected to the first tube The cable joint 3 is connected to the second pipe joint 6;

[0035] The flexible pipe cable sample cable 2 is a typical steel pipe composite umbilical cable sample cable, with a length of 2m and an outer diameter of 8 inches;

[0036] Adjusting the torque limit of the torque limiter 1, the torque limit of the torque limiter 1 is set to the design maximum torque value of the typical steel pipe composite umbilical cable;

[0037] The tension actuator 10 exerts tension and rotation on the flexible umbilical cable 2 through the torsion screw rod 4 .

Embodiment 3

[0039] A method for testing the tensile and torsion coupling performance of a flexible umbilical cable structure using the device for testing the tensile torsion coupling performance of a flexible umbilical cable structure described in Example 1. The two ends of the flexible umbilical cable sample cable 2 are respectively connected to the first tube The cable joint 3 is connected to the second pipe joint 6;

[0040] The flexible pipe cable sample cable 2 is a marine flexible riser sample pipe with a length of 2m and an outer diameter of 12 inches;

[0041] Adjust the torque limit value of the torque limiter 1, the torque limit value of the torque limiter 1 is set to the design maximum torque value of the marine flexible riser sample pipe;

[0042] The tension actuator 10 exerts tension and rotation on the flexible umbilical cable 2 through the torsion screw rod 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com