Multi-objective optimization design method for wheel

A multi-objective optimization and design method technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as limited optimization space, lack of parametric modeling, and automatic optimization design without joint call of performance calculation software , to achieve the effect of improving the optimization effect and optimizing the design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0064] Specific implementation mode 1. Combination Figure 1 to Figure 40 Illustrate this embodiment, the wheel multi-objective optimal design method, comprises the following steps:

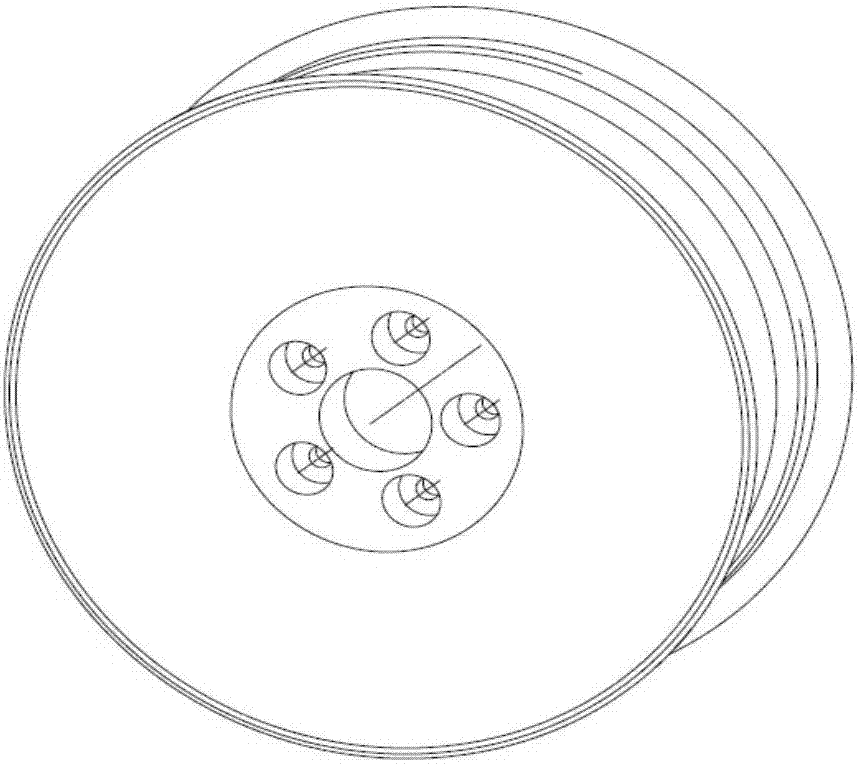

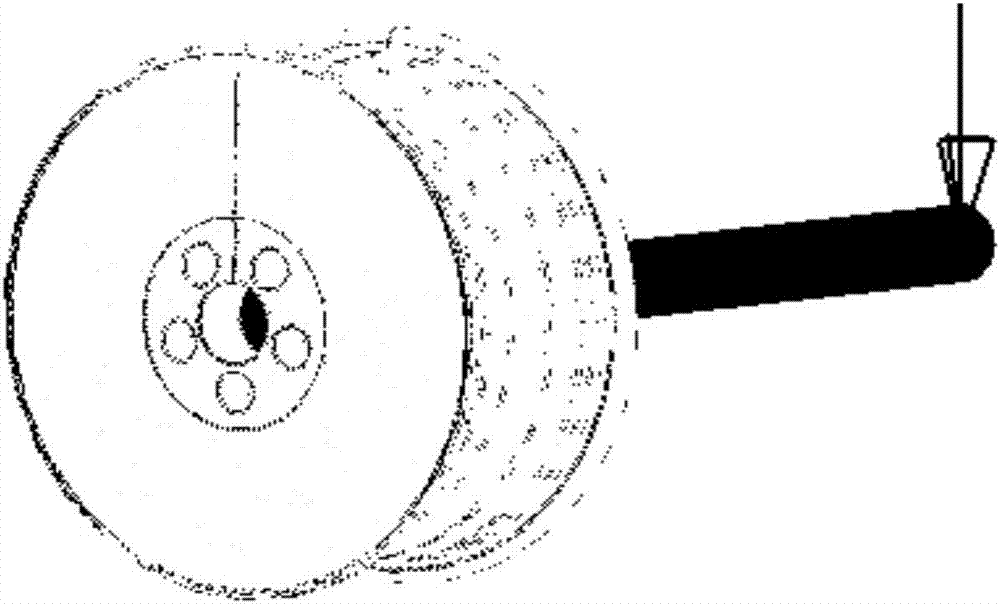

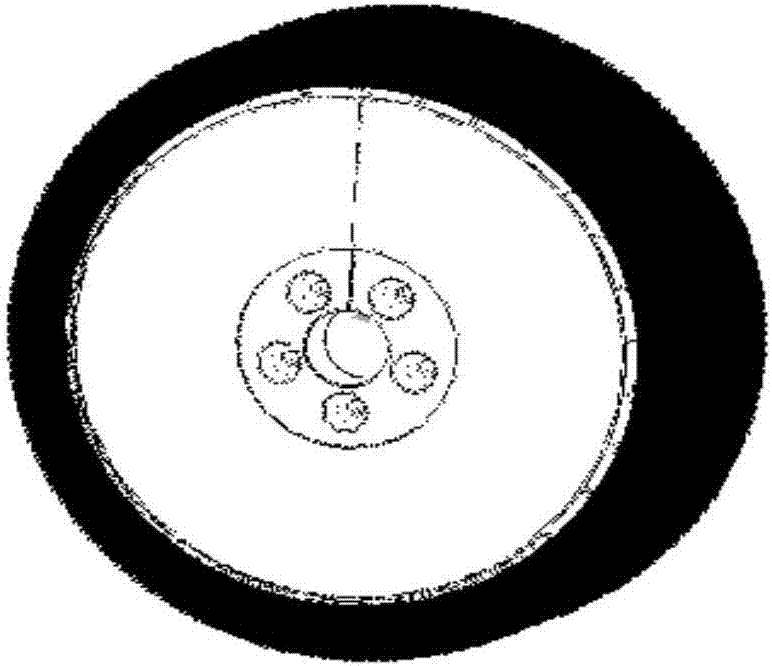

[0065] 1. Taking a certain type of wheel as the research object, establish a conceptual design model of the wheel in the 3D modeling software, such as figure 1 . According to the "Performance Requirements and Test Methods of Passenger Car Wheels" (GB / T 5334-2005), the wheel topology optimization based on the dynamic bending fatigue test and the dynamic radial fatigue test under the two working conditions were respectively established in the finite element preprocessing software model, respectively figure 2 and image 3 . Set the constraint conditions and objective function in the Optistruct software, add the minimum size constraint, the symmetry constraint of the rotating parts and the wheel processing constraint to the two topology optimization models respectively, and then perform topology...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com