Four-point bending fatigue test clamp

A technology of fatigue test and four-point bending, applied in measuring devices, instruments, scientific instruments, etc., can solve problems that are difficult to meet the needs of engineering practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

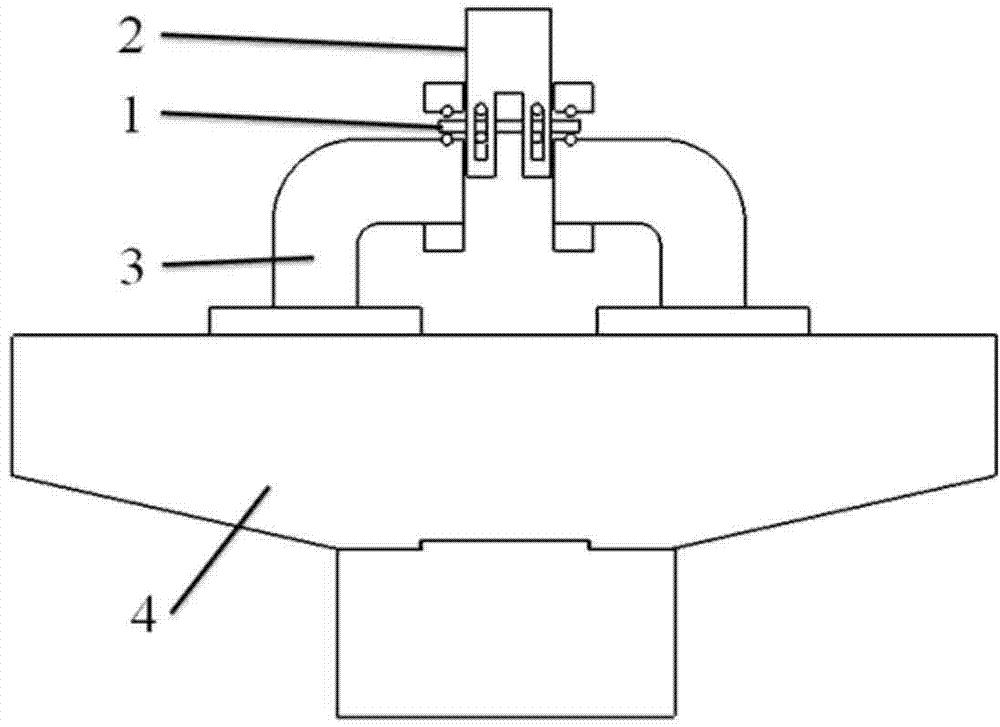

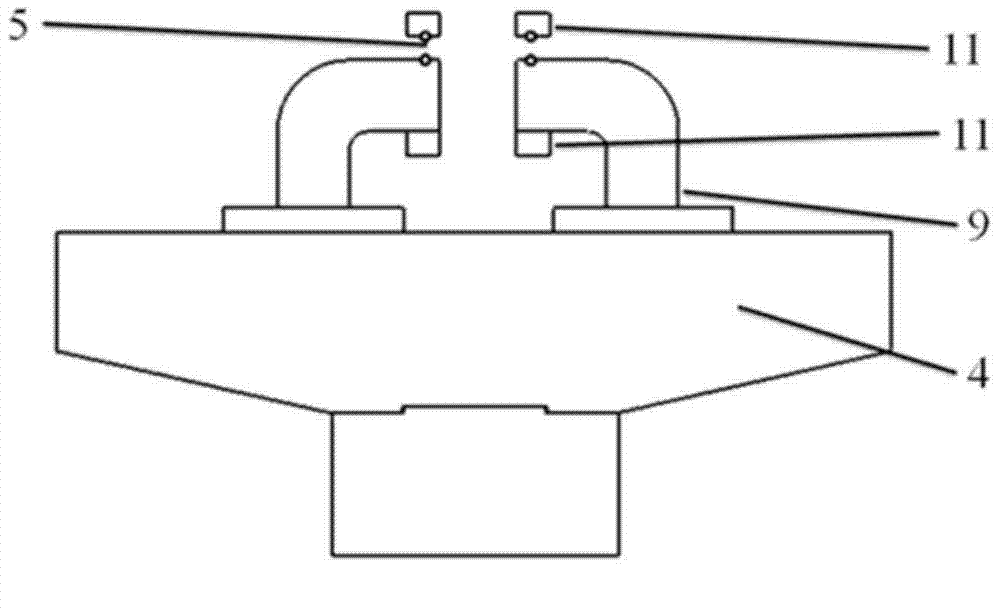

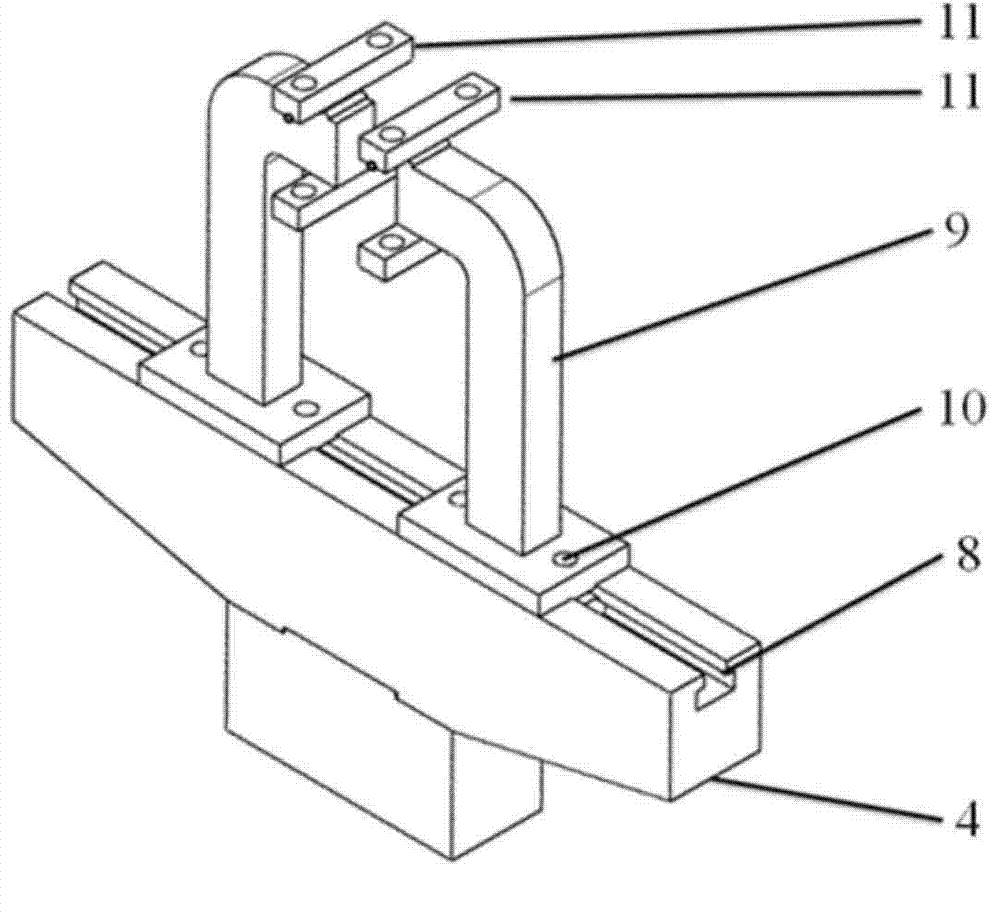

[0018] This embodiment is a four-point bending fatigue test fixture.

[0019] refer to Figure 1 to Figure 6 , the four-point bending fatigue test fixture consists of loading part 2, supporting part 3, base 4, pressure roller 5, specimen locking bolt hole 6, reinforcement plate 7, guide rail 8, supporting arm 9, supporting arm locking bolt hole 10, The specimen fastening device 11 is composed of the supporting part 3 and the loading part 2 respectively fixedly installed on the fatigue testing machine, the loading part 2 is installed on the middle upper part of the supporting part 3, and is coaxially fixedly installed with the supporting part 3; the supporting part 3 is used for Supporting the specimen 1 includes compression support and tension support; the loading part 2 applies pressure load and tension load to the specimen 1.

[0020] The base 4 of the support member 3 is provided with a guide rail 8 in the axial direction, and the guide rail 8 is a convex groove structure;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com