Resonance bending fatigue test machine for railway sleepers and application of resonance bending fatigue test machine

A bending fatigue and testing machine technology, applied in the field of testing machines, can solve the problems of cumbersome test operation, high cost, low efficiency, etc., and achieve the effects of cumbersome operation, ensuring accuracy, and convenient loading and unloading of test pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

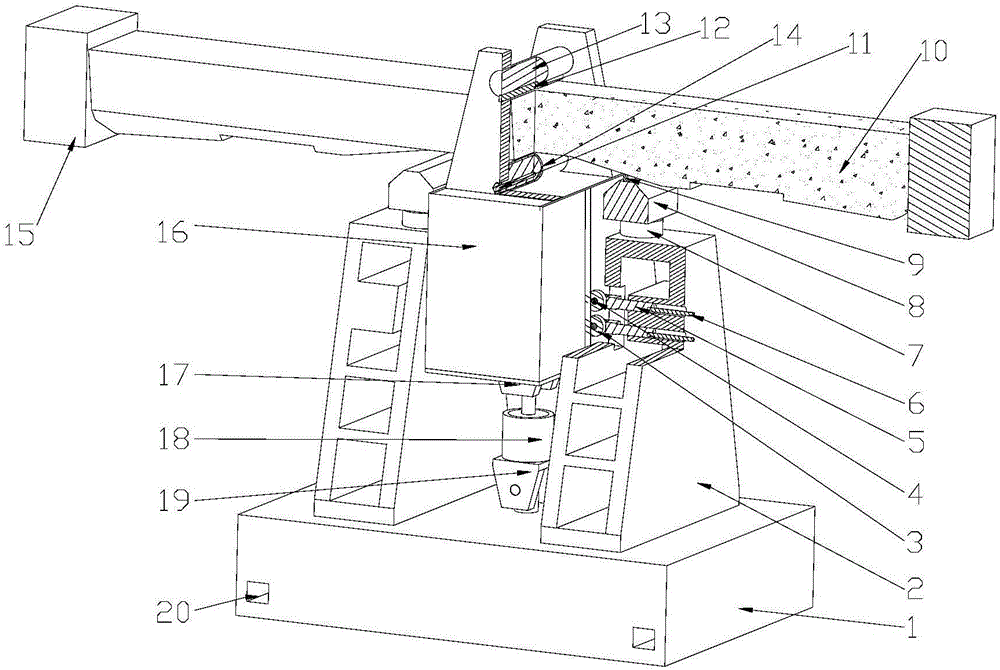

[0041] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

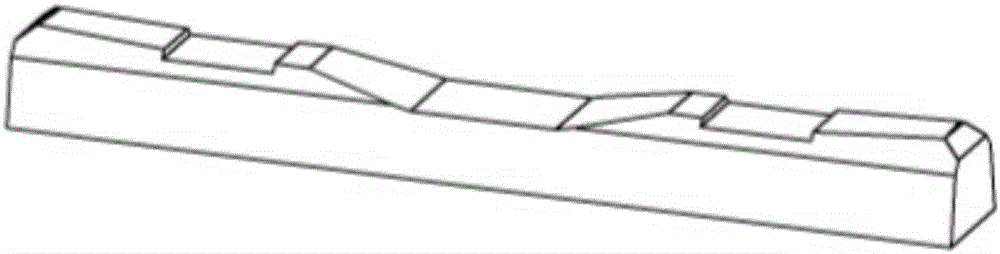

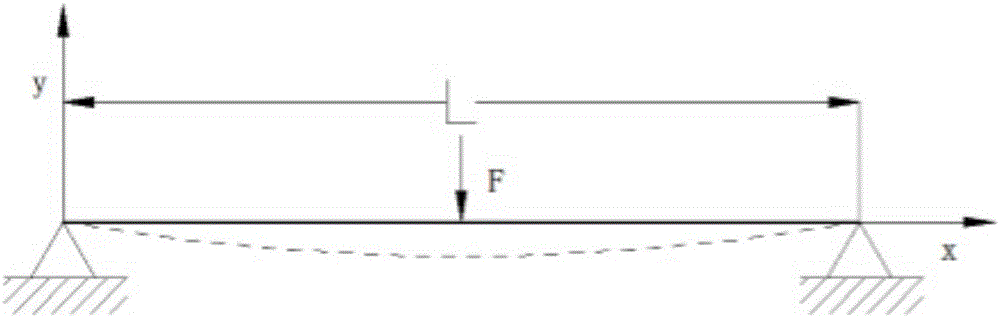

[0042]The invention proposes a railway sleeper fatigue test technology and device based on the theory of beam bending vibration mechanics and the resonance principle. It takes the beam-type specimen as the core, takes the simply supported form of the beam as the constraint condition, and applies a pulsating alternating excitation force to the specimen by using a special inertial vibrator and a constant force application device, so that the calculated and processed The specimen generates and maintains a resonance state, and completes the pulsation fatigue test at the fastest possible speed with the minimum energy input and the highest efficiency. The amplitude, frequency and constant force of the resonance are controlled by the controller according to the test stress level and detected by the detection device.

[0043] The technical principle of the inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com