Acoustic surface wave high-order nonlinear parameter representation method for bending fatigue state of metal plate

A bending fatigue, metal plate technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of undiscovered third-order nonlinear ultrasonic detection and characterization of the fatigue state of metal materials to predict the fatigue life of metal components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

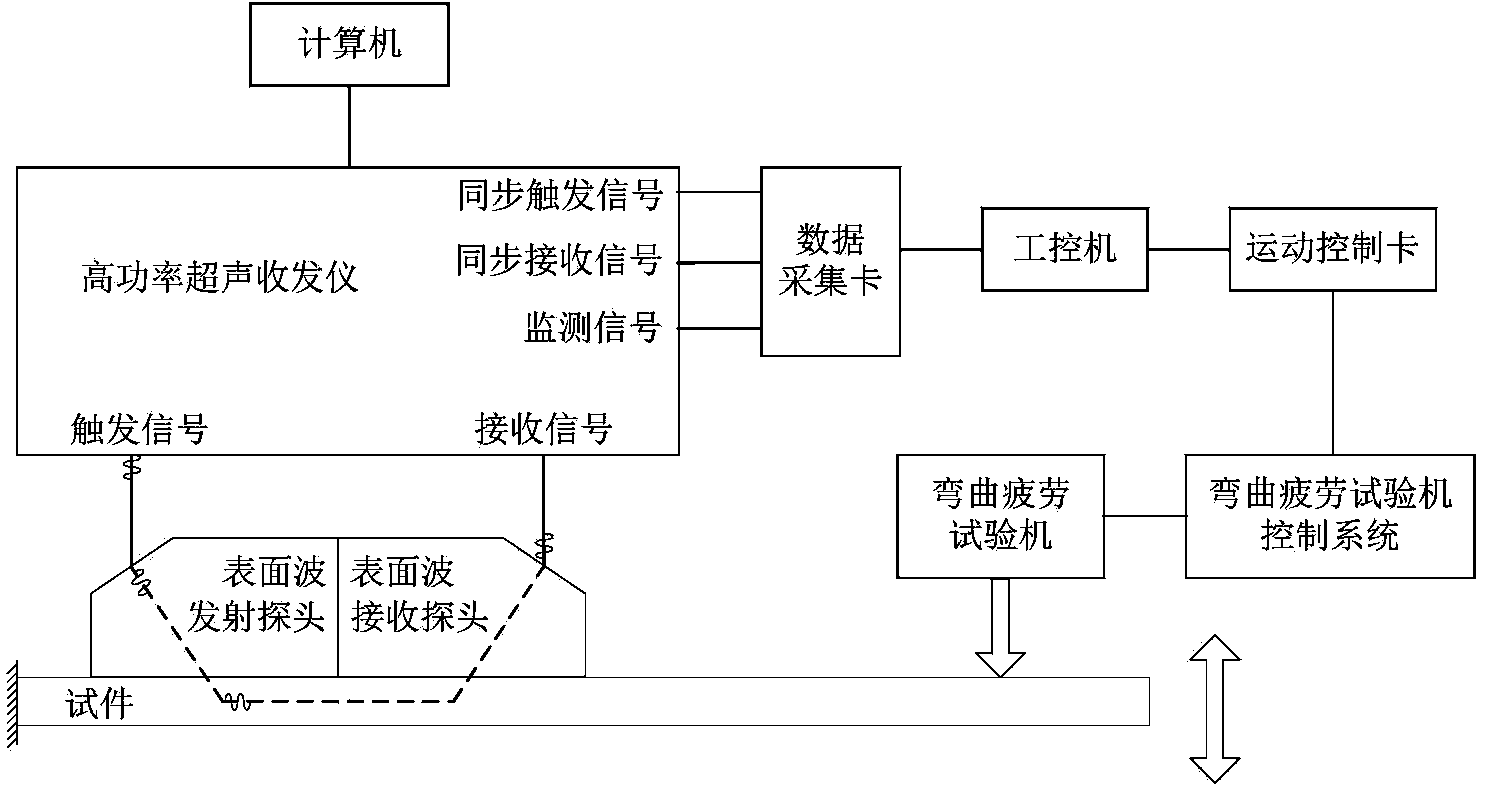

[0008] figure 1 It is a schematic diagram of the test device for the bending fatigue nonlinear ultrasonic testing system of metal plates, and each part is: metal plate fatigue test device, metal plate, ultrasonic transducer, high-power ultrasonic transceiver, computer, industrial computer, data acquisition card, motion control card Wait. Determine the cycle number, frequency and amplitude of the excitation signal according to the thickness of the metal sheet to be tested. Install the sheet metal on figure 1 On the metal plate fatigue bending test device, the transducer is installed on figure 1 Transducer position, connected to nonlinear ultrasonic testing system.

[0009] When considering a one-dimensional longitudinal wave propagating through a nonlinear medium, in the case of small strains, its equation of motion can be written as:

[0010] ρ ∂ 2 u ∂ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com