Crankshaft bend fatigue test system and method

A bending fatigue and test system technology, applied in the field of machinery, can solve the problems of poor authenticity and accuracy of test results and analysis results, lack of test organization and management methods, intelligence, and low level of automation, so as to reduce human participation, Ease of test operation and reduction of manpower burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below according to the accompanying drawings.

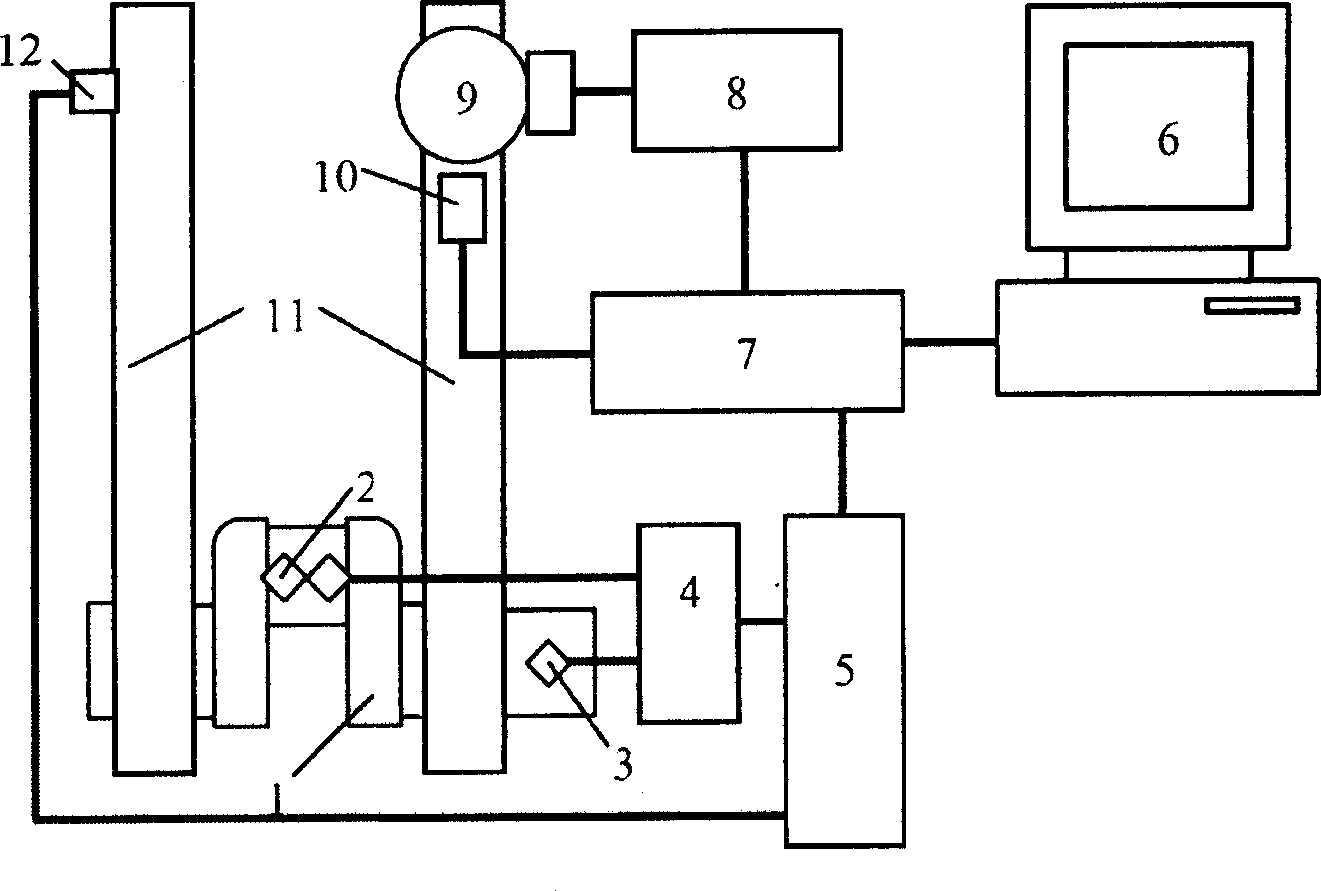

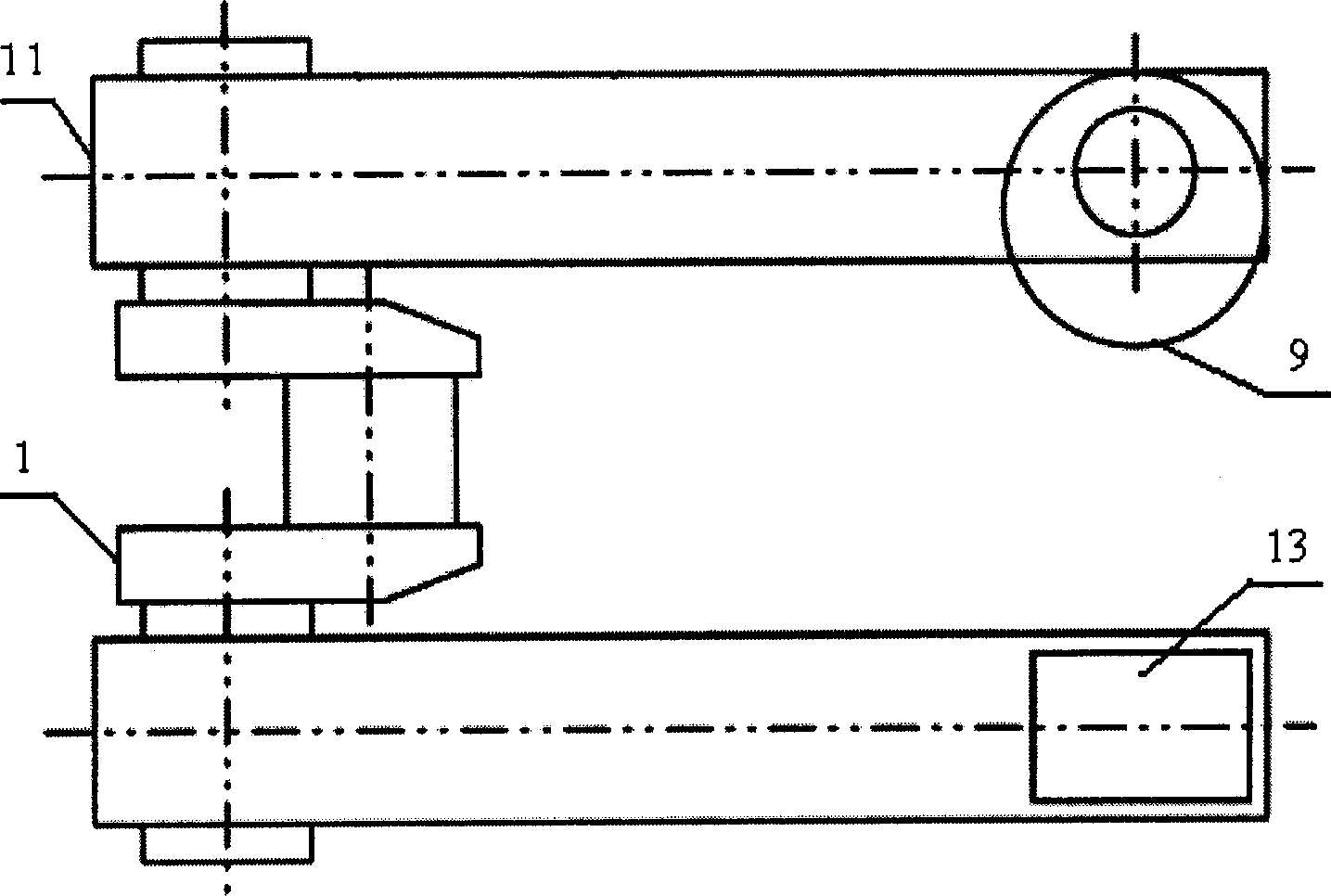

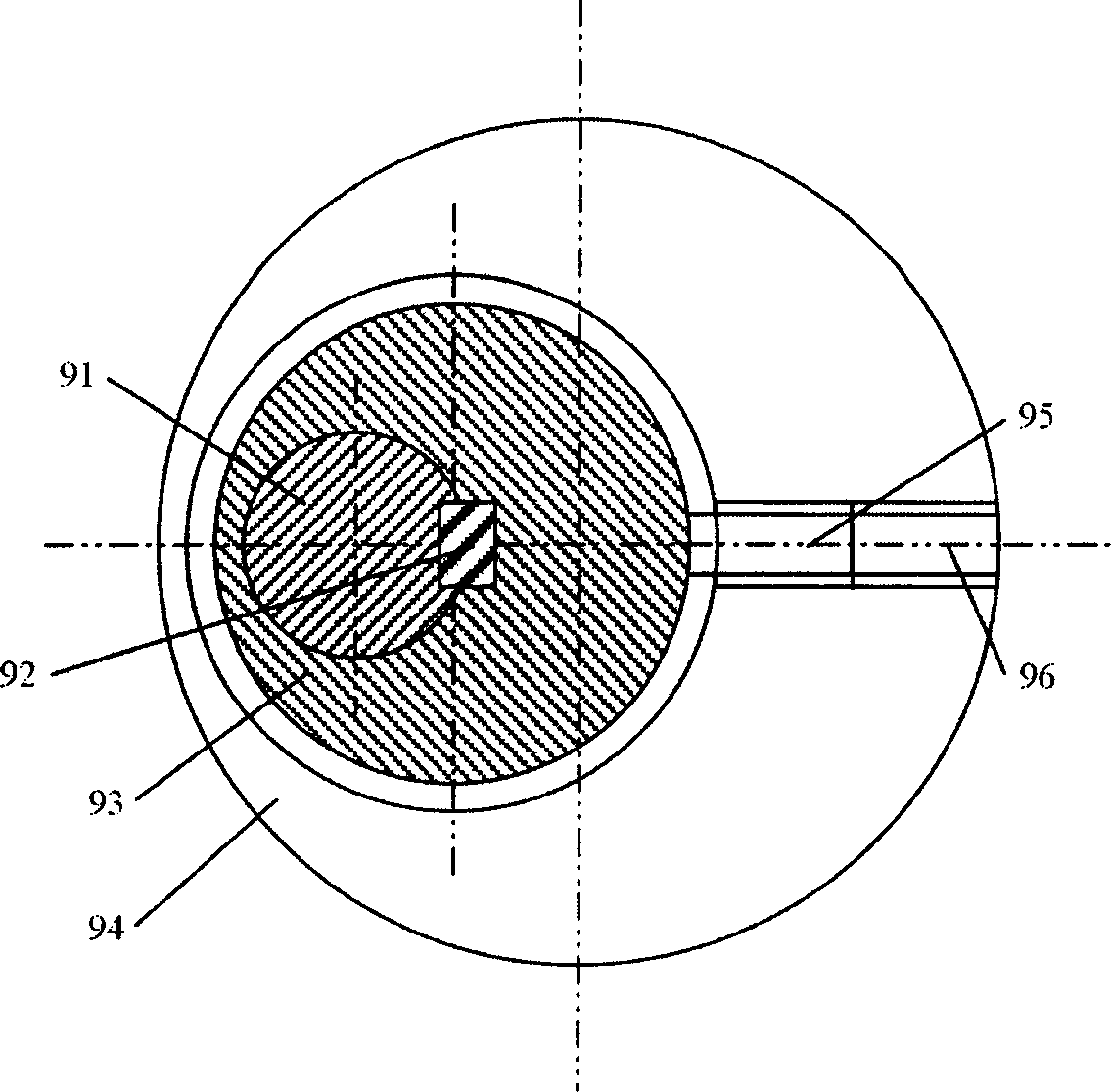

[0022] Figure 1~3 The detailed structure of the crankshaft bending fatigue test system of the present invention is shown. The present invention adopts a horizontal high-speed resonant platform with convenient operation and a loading mechanism with adjustable swing arm inertia and excitation torque; a computer with strong data management and calculation processing capabilities and a long-term stable operation capability and power-off The upper and lower units composed of programmable controllers with protection capabilities constitute the core of the system's measurement and control.

[0023] Such as figure 1 As shown, the crankshaft 1 and the swing arm 11 form a resonance platform. The strain gauge 2 is pasted on the rounded corner of the crankshaft 1, the compensation strain gauge 3 is pasted on the crankshaft 1, both the strain gauge 2 and the compensation strain gaug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com