Rotating and bending corrosion fatigue testing device

An experimental device and corrosion fatigue technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, test wear resistance, etc., can solve the problems that the data cannot be used as the basis for engineering design, and cannot truly reflect the working state, etc., to achieve structural Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

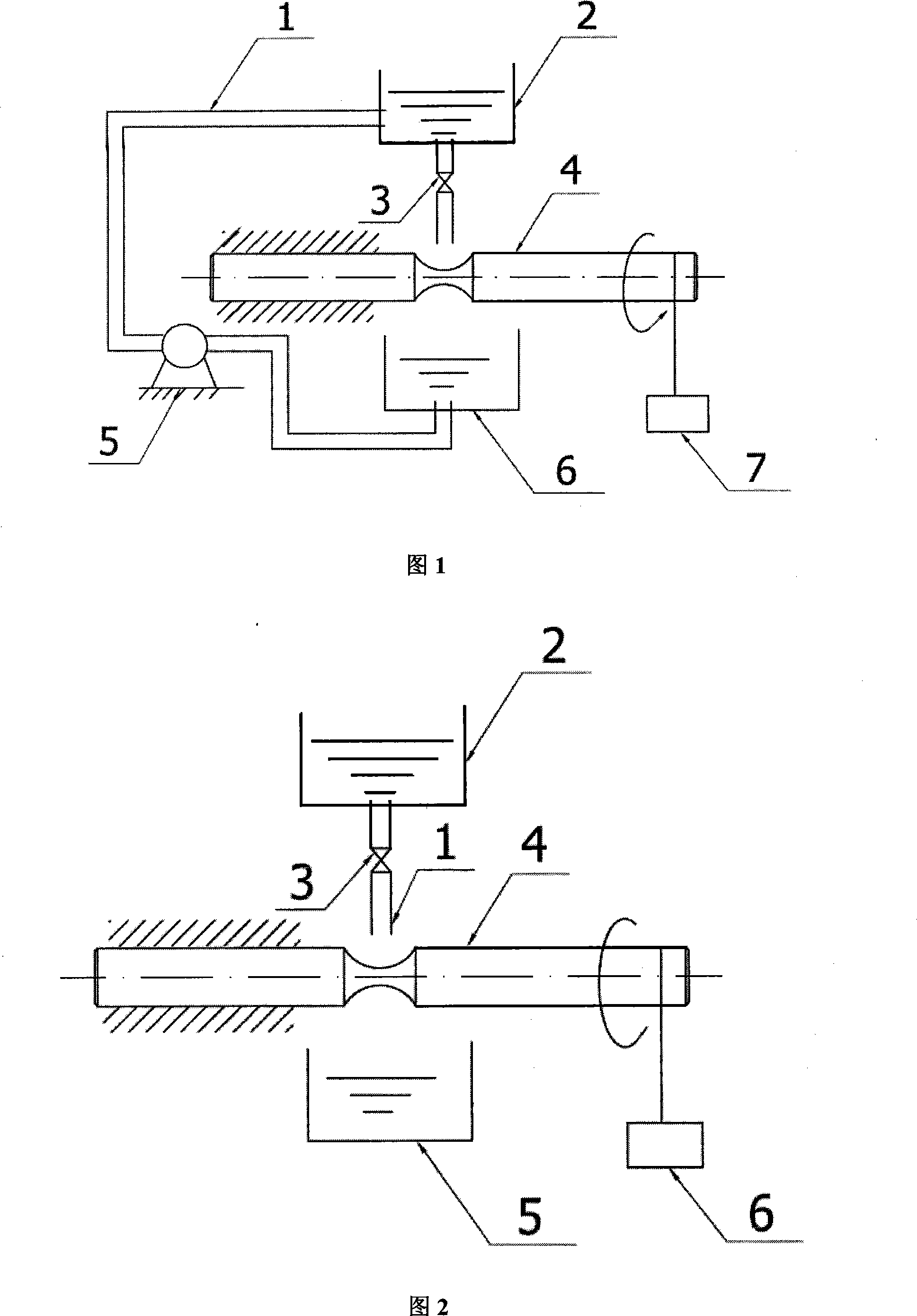

Embodiment 1

[0016] The device shown in Figure 1 includes a corrosive liquid supply system composed of a liquid storage tank 2, a valve 3, an infusion pump 5, a pipeline 1, and a recovery tank 6, and a rotating fatigue test device 8, wherein the rotating fatigue test device 8 adopts an existing The experimental device that has, this experimental device is equipped with loading weight 7 by itself. The test piece 4 is mounted on the rotating fatigue test device 8, the liquid storage tank 2 and the corrosive liquid output port of the corrosive liquid supply system are set above the test piece 4, and the recovery tank 6 is set under the test piece 4.

[0017] During the experiment, the rotating fatigue test device 8 drives the test piece 4 to rotate, and uses the loading weight 7 to apply a bending load to it. At the same time, the corrosive test solution drips on the surface of the test piece 4 through the pipeline under the action of gravity, so that the test solution Continuously dripping o...

Embodiment 2

[0020] FIG. 2 is a schematic diagram of the second embodiment of the present invention, and the settings of the infusion pipeline 1 and the valve 3 are the same as those in the first embodiment. However, in this embodiment, after the test solution drops into the recovery tank 5, it is not recycled and stored directly. It is suitable for testing the corrosion fatigue performance of materials in highly volatile media.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com