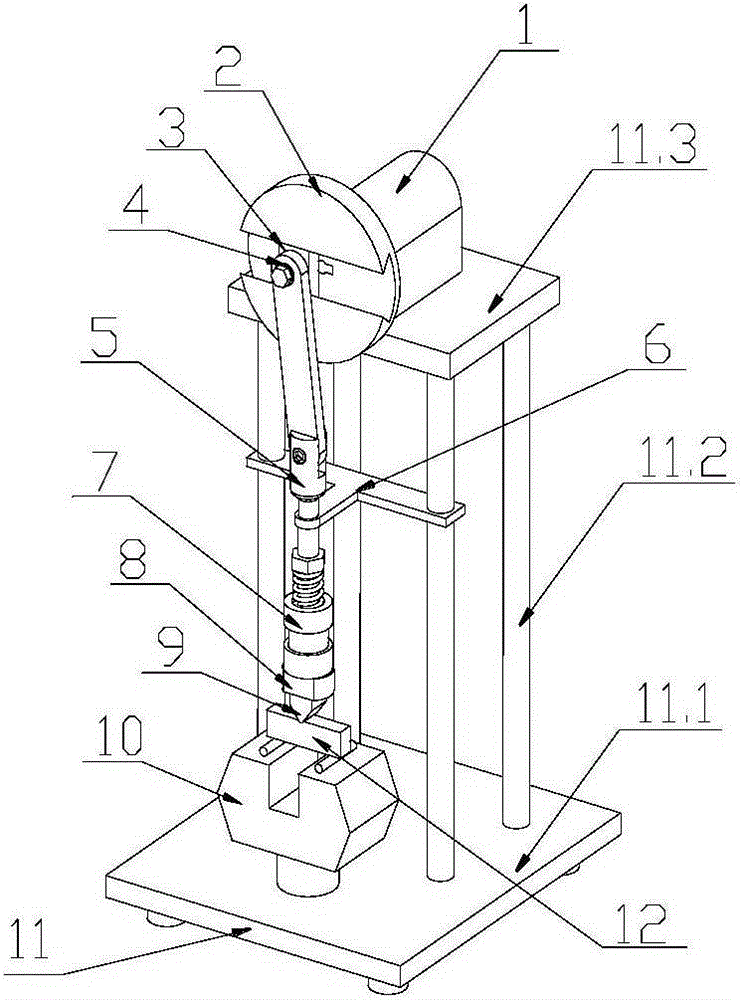

Three-point bending fatigue testing machine

A fatigue testing machine, three-point bending technology, applied in the direction of testing the strength of materials by applying a stable bending force, to achieve the effect of simple structure, low cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

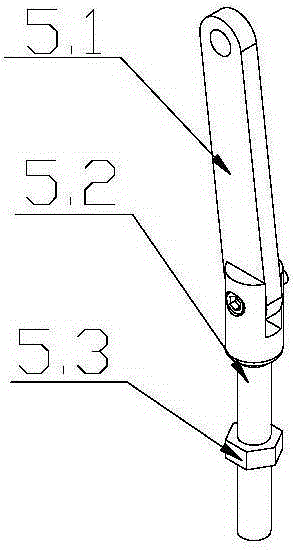

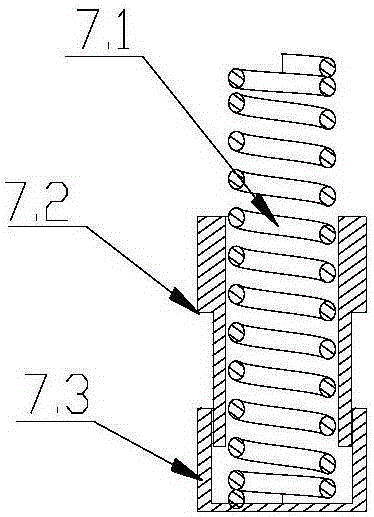

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] The invention relates to the technical field of detection equipment, and is mainly applicable to the three-point bending fatigue performance detection of a sample, in particular to the three-point bending fatigue performance detection of a higher frequency (30-300 Hz) loading mode with adjustable loading conditions.

[0014] The purpose of the present invention is to provide a three-point bending fatigue testing machine for the deficiencies of the existing three-point bending fatigue testing technology, which solves the problems of the current three-point bending fatigue testing, such as excessive volume, high price, complex equipment structure, and inability to At the same time, adjust the loading amplitude and pre-stress. A three-point bending fatigue testing machine of the present invention is simple in structure and low in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com