Fatigue crack three-dimensional expansion comparative analysis method for off-line CT detection condition

A technology for fatigue crack detection and detection conditions, which is applied in the direction of testing material strength by applying stable bending force and testing material strength by applying repetitive force/pulsation force, and can solve problems such as inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

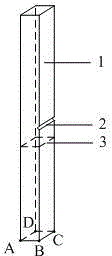

[0020] Such as figure 1 As shown, the fatigue crack growth three-point bending fatigue sample 1 is processed by mechanical processing method, and the sample size is 60mm (length) × 5mm (width) × 5mm (height). A V-shaped notch 2 with a length of 5 mm × width of 1 mm × depth of 0.5 mm is processed by the spark method. The surface is polished with fine sandpaper, and the smoothness reaches above 7.

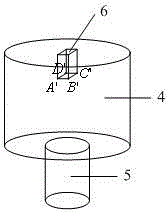

[0021] Such as figure 2 As shown, the CT scanning positioning device includes a disc 4 with a diameter of 40 mm, a disc 5 with a diameter of 20 mm, and a square hole 6 with a flat bottom. The center position of the upper surface of , the size is 5mm (length) × 5mm (width) × 10mm (depth), and the CT scanning positioning device is fixed at the center of the CT rotating table.

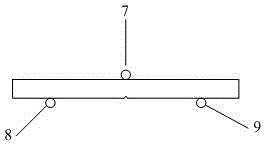

[0022] The three-point bending fatigue test was carried out on the three-point ben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com