Rock-fill object density measure system

A test system and rockfill body technology, applied in the field of rockfill dam density testing, can solve the problems of test result error, large cost, time-consuming, etc., and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

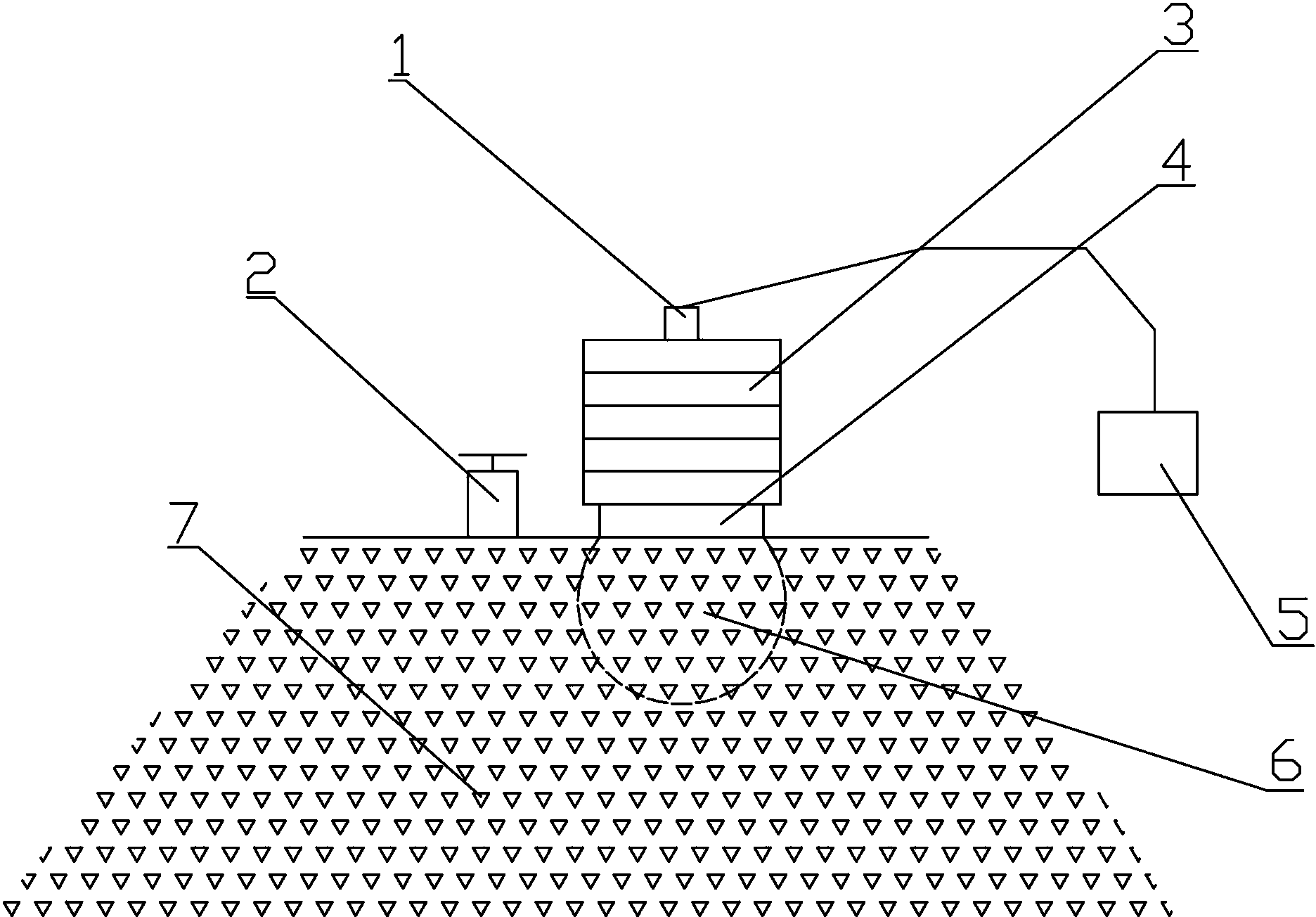

[0038] Such as figure 1 Among them, a kind of rockfill body density test system, it comprises:

[0039] The bearing plate 4 placed on the surface of the rockfill body 7;

[0040] The counterweight 3 stacked on the pressure bearing plate 4;

[0041] An exciting hammer 2 for providing an exciting force located on one side of the pressure bearing plate 4;

[0042] The geophone 1 installed on the upper surface of the counterweight 3;

[0043] The wave detector 1 is electrically connected with the vibration frequency tester 5 .

[0044] Preferably, the pressure bearing plate 4 and the counterweight 3 are cylinders.

[0045] Preferably, the weight of the vibrating hammer 2 is 40-60 kg.

[0046] Preferably, the edge of the vibrating hammer 2 is 100-150 mm away from the edge of the pressure bearing plate 4 .

[0047] Preferably, the detector 1 is a velocity detector.

[0048] Preferably, 15-25mm of fine sand is provided between the bearing plate 4 and the rockfill body 7 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com