Spacial three-dimensional special-shaped bridge pier rebar construction method based on BIM modelling technology

A construction method and steel bar technology, applied in buildings, bridges, bridge parts, etc., can solve the problems of low precision, materials, labor and long time, and achieve the effects of improving precision, improving work efficiency, saving construction period and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

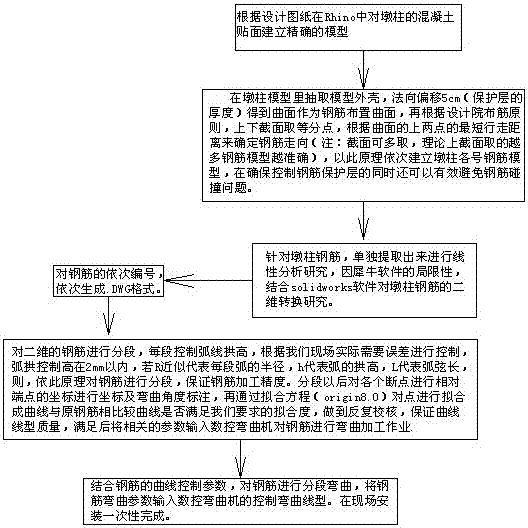

[0019] The invention relates to a method for constructing steel bars of three-dimensional special-shaped bridge piers based on BIM modeling technology, comprising the following steps:

[0020] (1) Establish the pier column model: according to the design drawings, establish an accurate model for the concrete veneer of the pier column in Rhino;

[0021] (2) Determining the direction of reinforcement: extract the model shell from the pier column model, offset the normal direction by 5cm (thickness of the protective layer) to obtain a curved surface as the reinforcement layout surface, and then take equal points for the upper and lower sections according to the principle of the design institute’s reinforcement layout, according to The shortest walking distance of the upper two points on the curved surface is used to determine the direction of the steel bar (multiple cross-sections can be taken, in theory, the more steel bar models are taken, the more accurate the steel bar model wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com