Multi- sensor system fault self-diagnosis method

A multi-sensor, system failure technology, applied in the direction of instruments, measuring devices, measuring electricity, etc., can solve problems such as unreliability, increase system complexity and system construction cost, and achieve the effect of increasing reliability and simplifying system structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

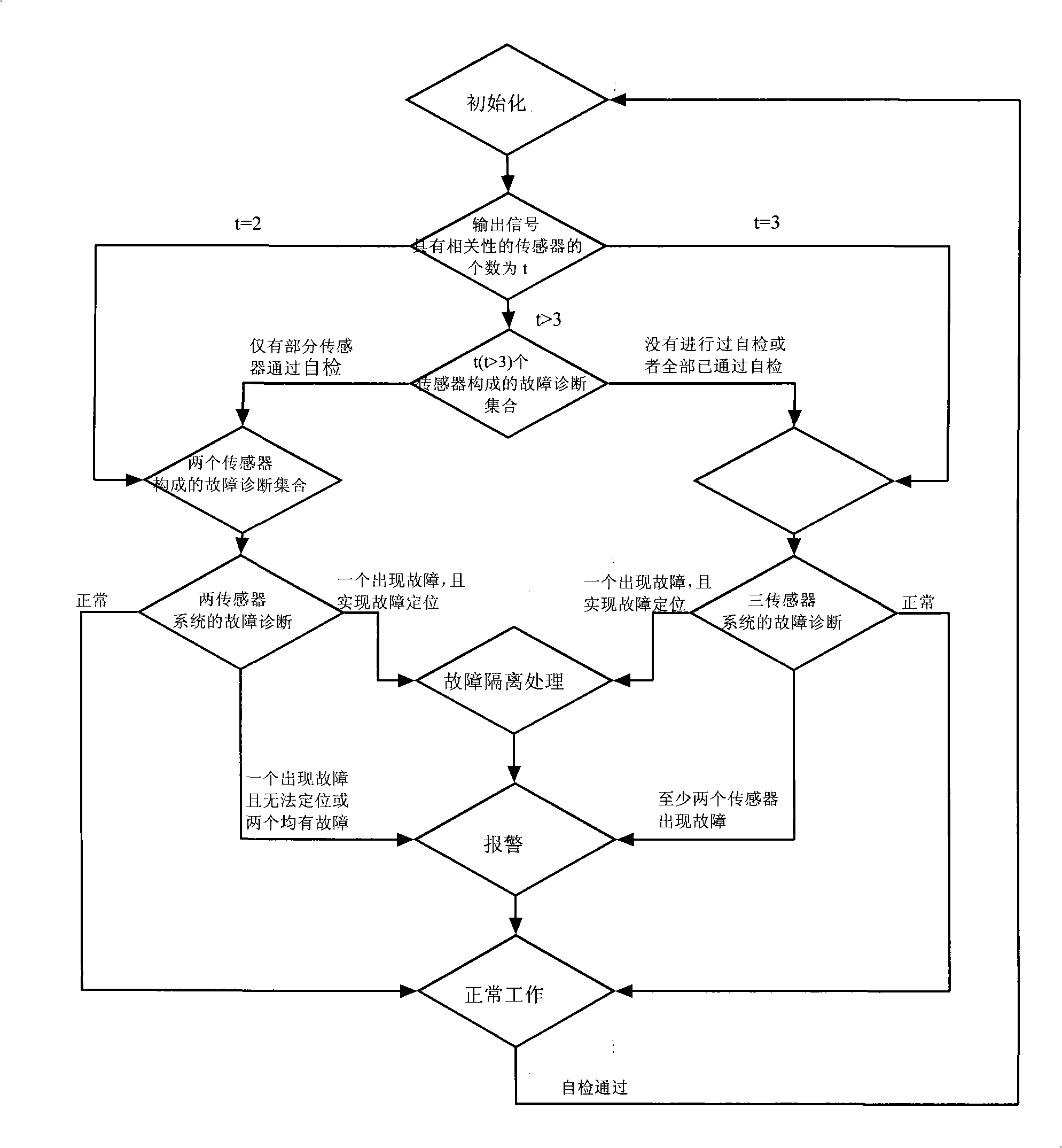

[0023] Such as figure 1 Shown, a kind of multi-sensor system fault self-diagnosis method of the present invention comprises the following steps:

[0024] Step 1, initialization, to determine the self-test status and number of sensors whose output signals are correlated in the known multi-sensor system, for a multi-sensor system including t sensors with correlated outputs, that is, the output signals are correlated The number of sensors is t. When t is greater than 3, go to step two; when t=3, go to step three; if t=2, go to step four.

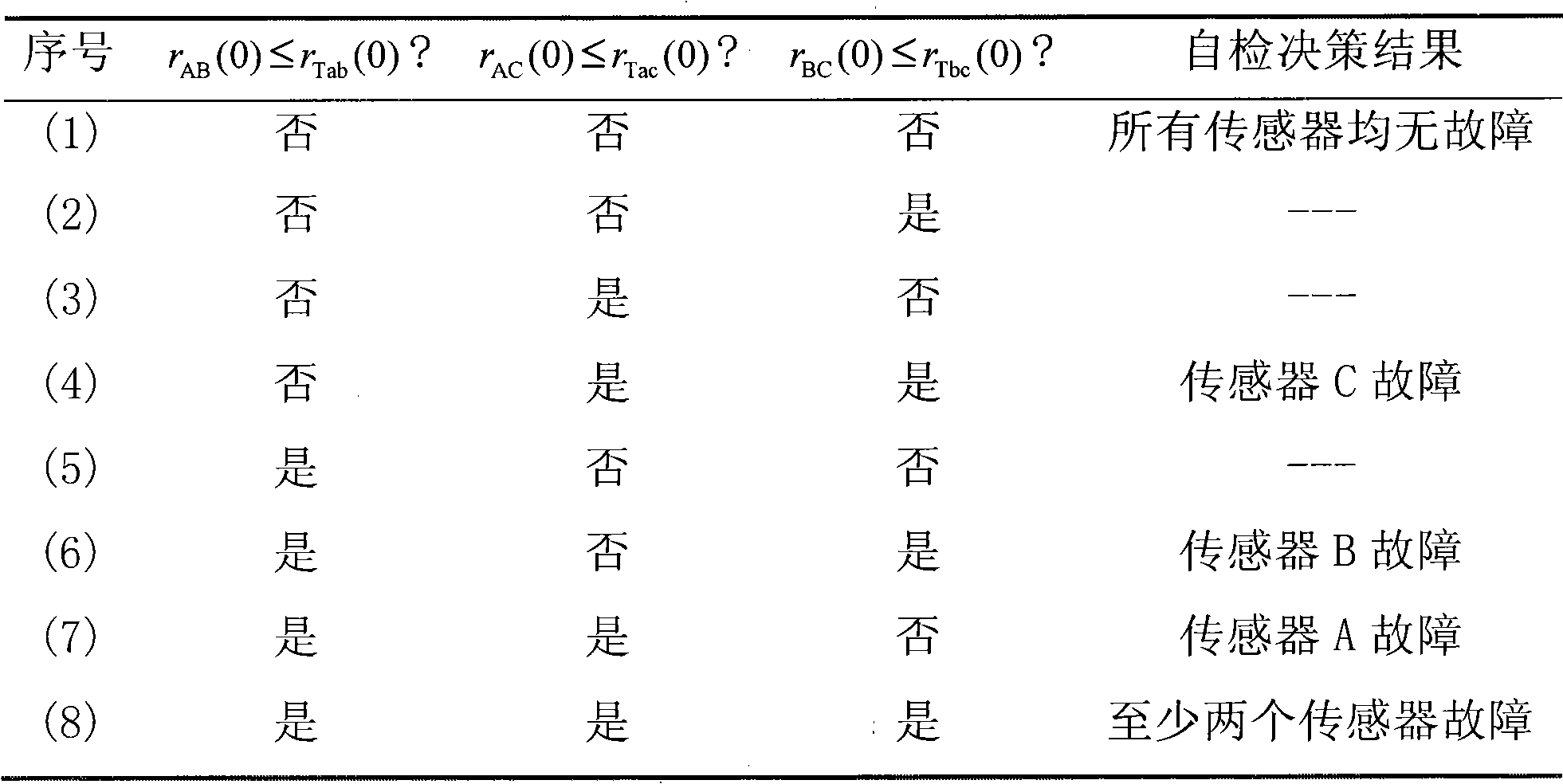

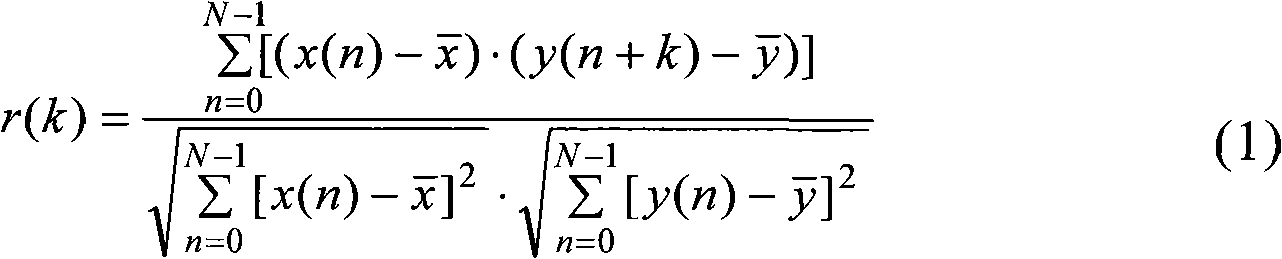

[0025] Step 2, when the number of sensors used in the sensor system is t and t>3, first judge whether m sensors have undergone self-inspection, and 0

[0026] If there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com