Method for establishing CAE linear analysis sub-assembly connection relation

A connection relationship and sub-assembly technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficult to determine the connection position, inaccurate simulation calculation results, and many assemblies required for analysis of working conditions, etc. , to achieve the effect of fast update, time saving and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

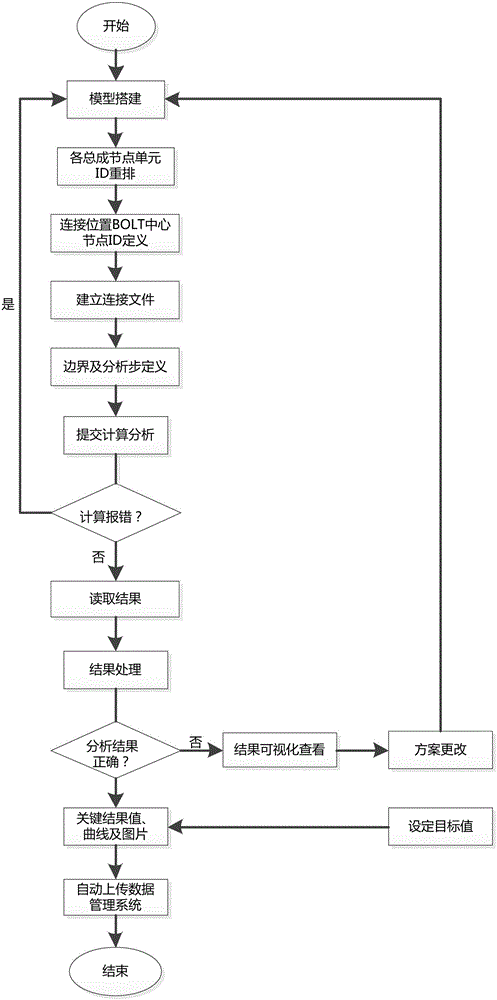

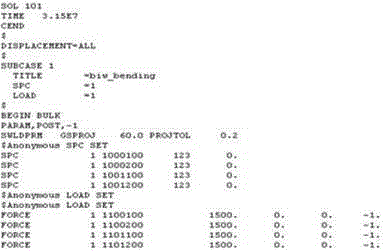

[0011] Combine the following figure 1 , the content of the present invention will be described in detail through specific embodiments. Based on the established finite element mesh model, the connection files between the assemblies are established, and the method for establishing the connection relationship between the sub-assemblies for CAE linear analysis includes the following steps:

[0012] 1) Divide the assembly: In the CAE linear analysis, in order to facilitate and unify the management of the linear analysis model, the linear analysis model is divided into nine parts according to the vehicle design process (①white body; ②hatch cover; ③left and right front door; ④left and right rear door (or sliding door); ⑤ sub-frame; ⑥ trunk lid (or tailgate); ⑦ front-end module; CAE analysis), each of which is independent.

[0013] ) to define the unit number segment of the assembly node: According to the assembly divided in step 1), use ANSA pre-processing software to define th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com