Simulation evaluation method of compressor piping vibration of constant frequency air conditioner

A simulation evaluation and compressor technology, applied in design optimization/simulation, instruments, special data processing applications, etc., can solve problems such as accurate judgment of piping natural frequency points, piping modal analysis cannot be quantified, etc., to improve the success of trial production The effect of reducing the rate, reducing the experiment cost and reducing the design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

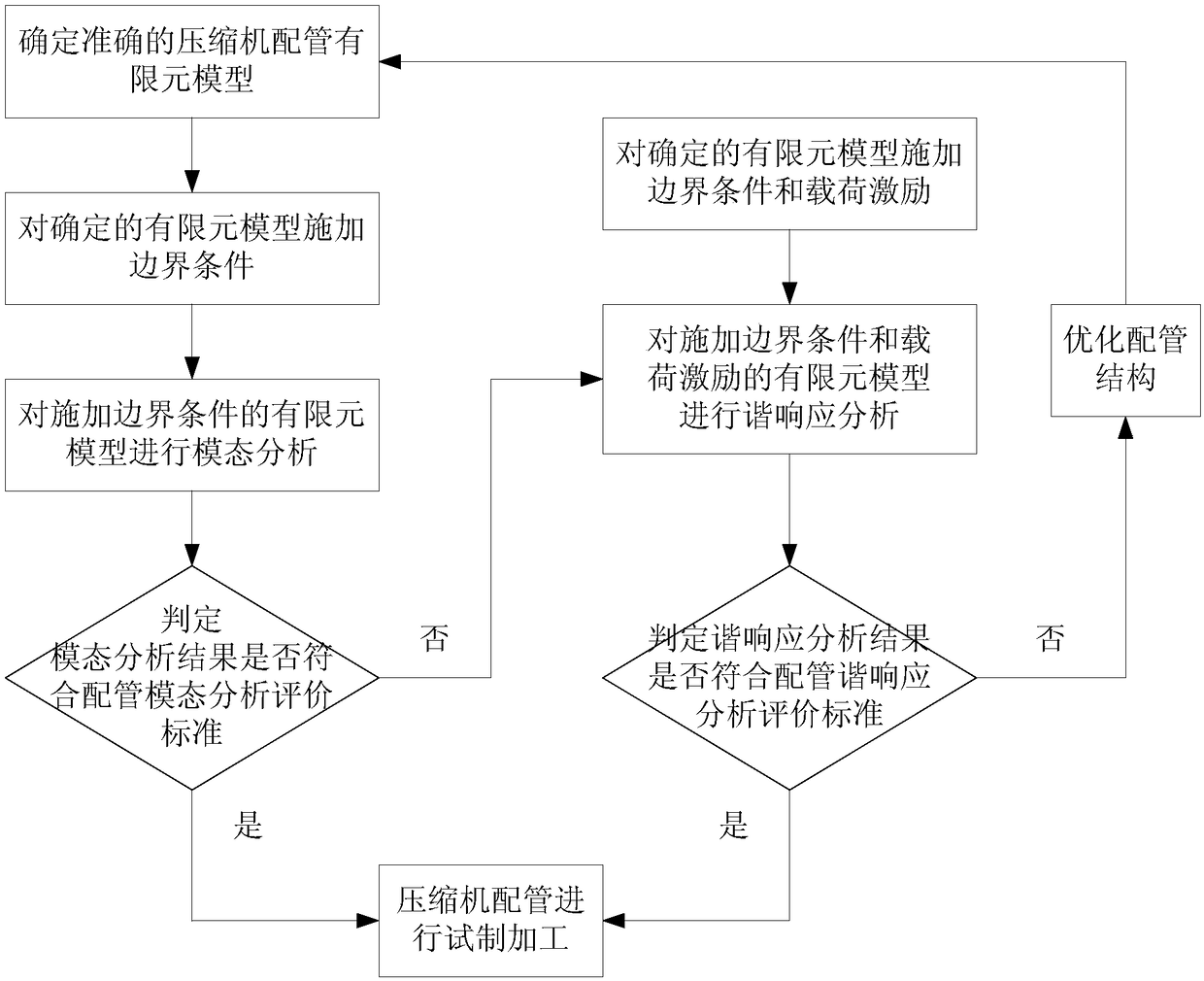

[0037] The flow chart of the simulation evaluation method for the vibration of the compressor piping of the fixed-frequency air conditioner in this example can be found in figure 1 , wherein, the embodiment of the present invention fixed-frequency air conditioner compressor piping simulation evaluation method for vibration, comprising the following steps:

[0038] a. Determine the accurate finite element model of compressor piping;

[0039] b. Apply boundary conditions to the determined finite element model and perform modal analysis on it;

[0040] c. Determine whether the modal analysis results in step b meet the piping modal analysis evaluation criteria, if so, proceed to step f, otherwise proceed to step d;

[0041] d. Apply boundary conditions and load excitation to the determined finite element model and perform harmonic response analysis on it;

[0042] e. Determine whether the harmonic response analysis result in step d meets the piping harmonic response analysis eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com