Four-axis blade measurement system and method

A measurement system and blade technology, applied in the direction of measurement devices, instruments, optical devices, etc., can solve the problems of high cost, low efficiency, bad working environment, etc., and achieve the effect of reducing labor costs, improving work efficiency, and increasing company benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically and completely described below in conjunction with specific embodiments. The specific technical solutions are only used to illustrate the present invention, not to limit it, and those skilled in the art should understand that all other technical solutions obtained without creative work belong to the protection scope of the present invention.

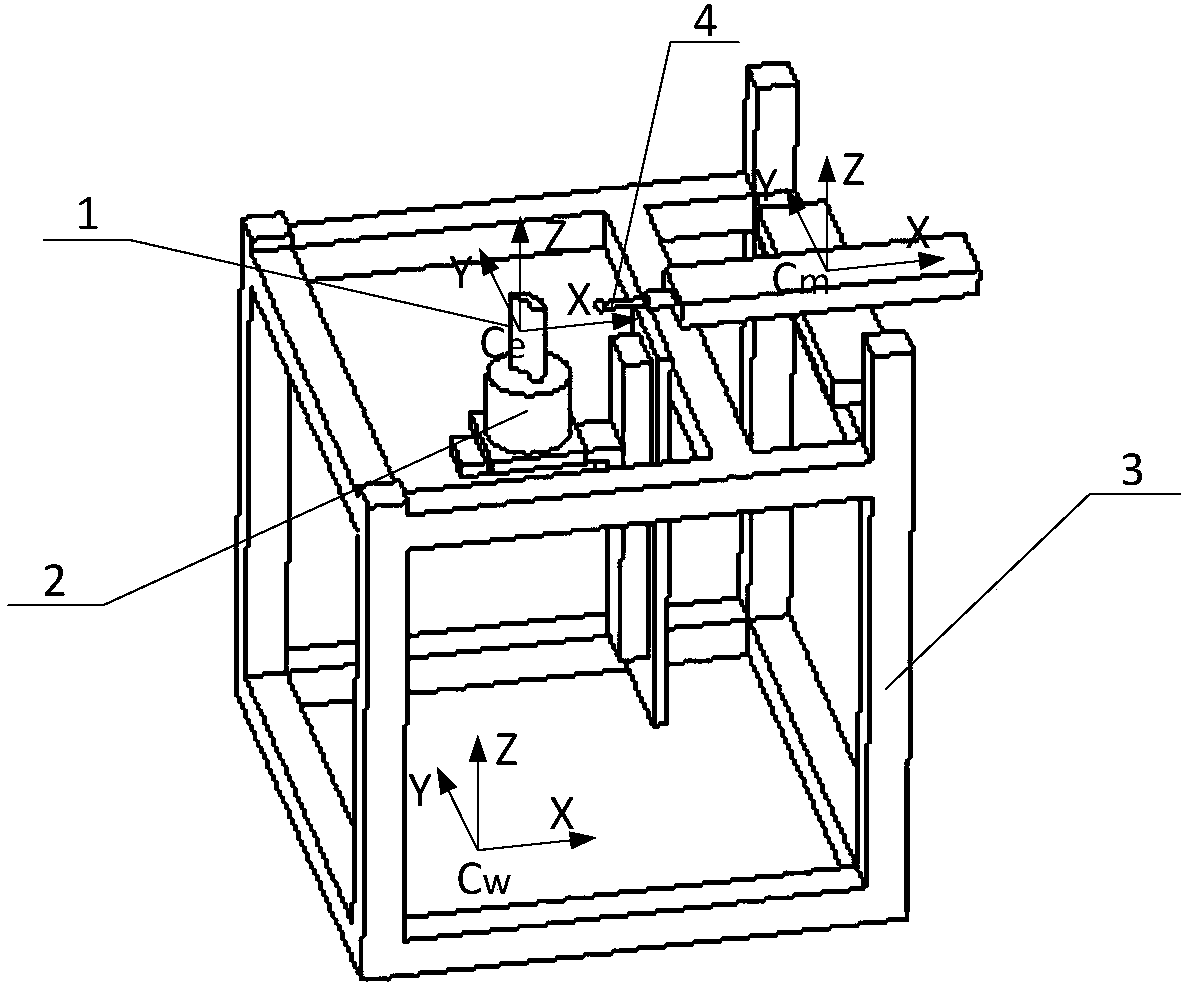

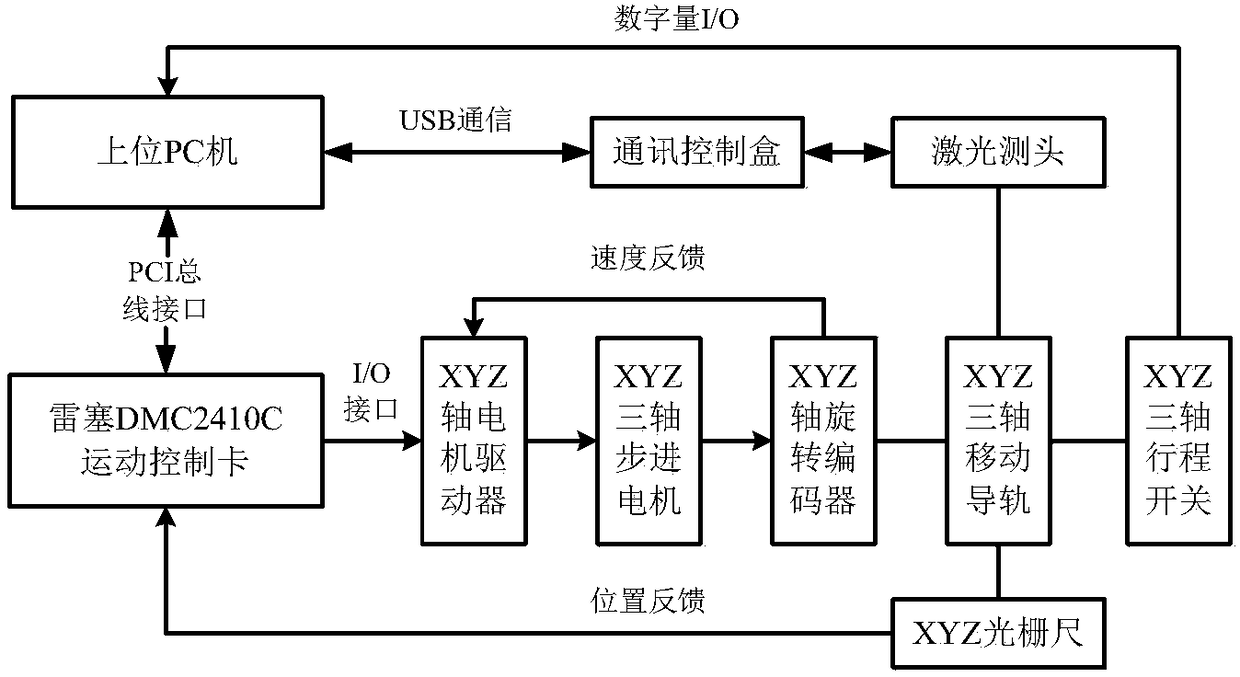

[0038] see Figure 1-4 , the length of the blank airfoil of the blade is 155mm, the width is 80mm, the minimum thickness is 4mm at the front and rear edges, and the airfoil is a complex curved surface. The specific steps of a blade measurement system and method of the present invention are as follows:

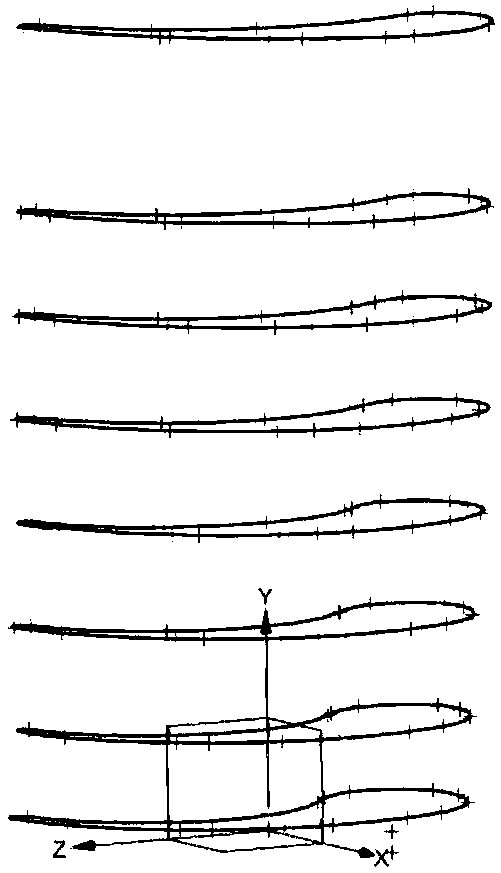

[0039] Step 1: Use the "3-2-1" method to establish the blade coordinate system, measure three points on the bottom plane of the blade root to construct the direction, measure two points on the side of the back d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com