Preparation method of sectional chemical milling sample plate

A chemical milling template and segmented technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of large curvature changes, chemical milling templates and molds do not fit, affect the processing progress of chemical milling parts, etc. problem, to achieve the effect of improving the design cycle and facilitating the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0032] A segmented chemical milling template preparation method, the specific steps are as follows:

[0033] Step 1) Design the chemical milling process model

[0034] The process model is a digital model formed after adding process elements to the product model, and is one of the data sources for digital manufacturing and mold design;

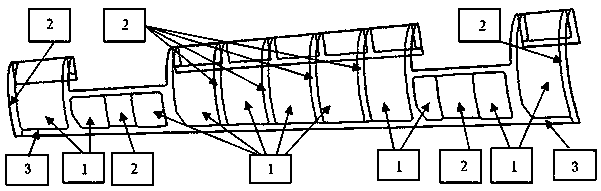

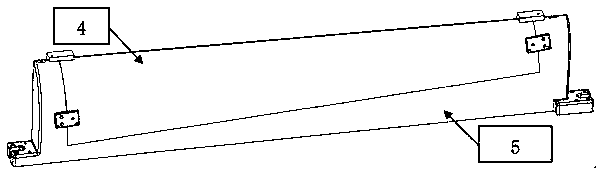

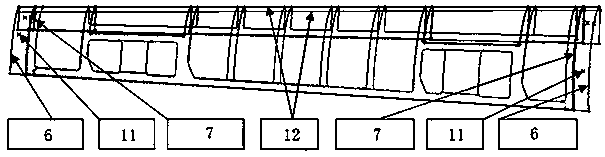

[0035] The chemical milling process model is a special process model established for the manufacture of three-dimensional chemical milling templates for curved surface parts. It is the original basis for manufacturing chemical milling samples. And chemical milling allowance line and other information, linked to form the part forming mold model, which is a three-dimensional solid model established according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com