Multipoint laser

A laser and multi-point technology, applied in the direction of instruments, simulators, computer control, etc., can solve the problems of extended design cycle, high difficulty, complex optical system, etc., achieve the effect of reducing development and production costs and speeding up the design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

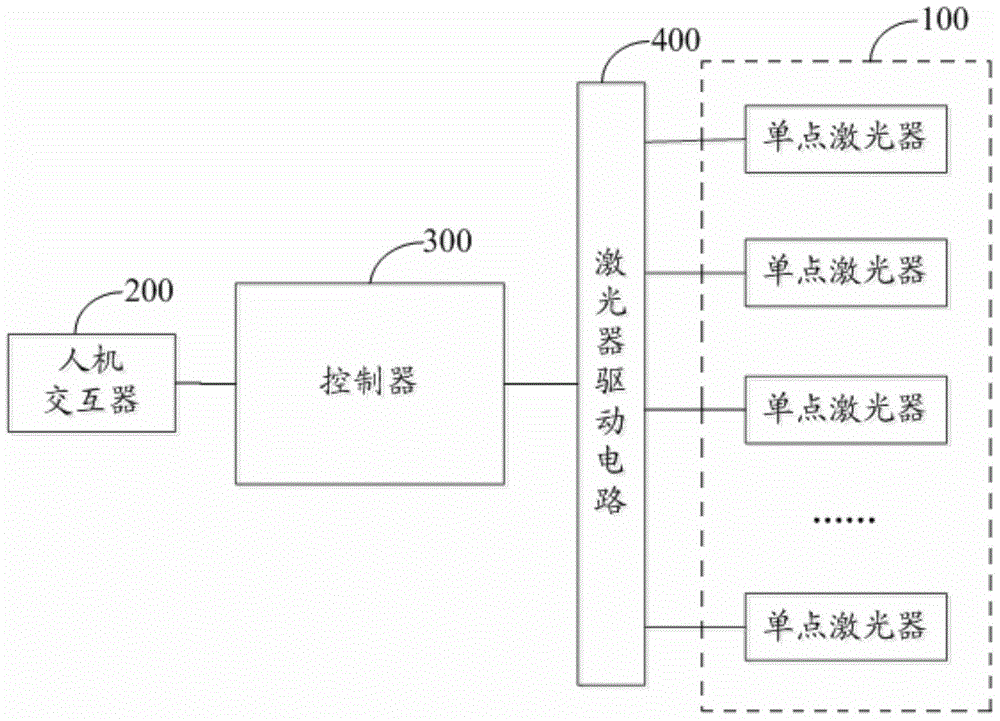

[0024] Embodiment 1 of the present invention discloses a multi-point laser, please refer to figure 1 , the multi-point laser includes N single-point lasers 100 , a human-computer interface 200 , a controller 300 and a laser driving circuit 400 .

[0025] N single-point lasers 100 are used as N light-emitting points, where N is a natural number greater than 1.

[0026] Specifically, the value of N can be determined according to actual application requirements. For example, when four-point lasers are required, N takes a value of 4, and when five-point lasers are required, N takes a specific value of 5. In this embodiment, a five-point laser is taken as an example The present invention will be described in detail.

[0027] The human-computer interaction device 200 is connected with the controller 300 for realizing human-computer interaction.

[0028] Wherein, the human-computer interaction device 200 specifically implements human-computer interaction in the form of buttons.

...

Embodiment 2

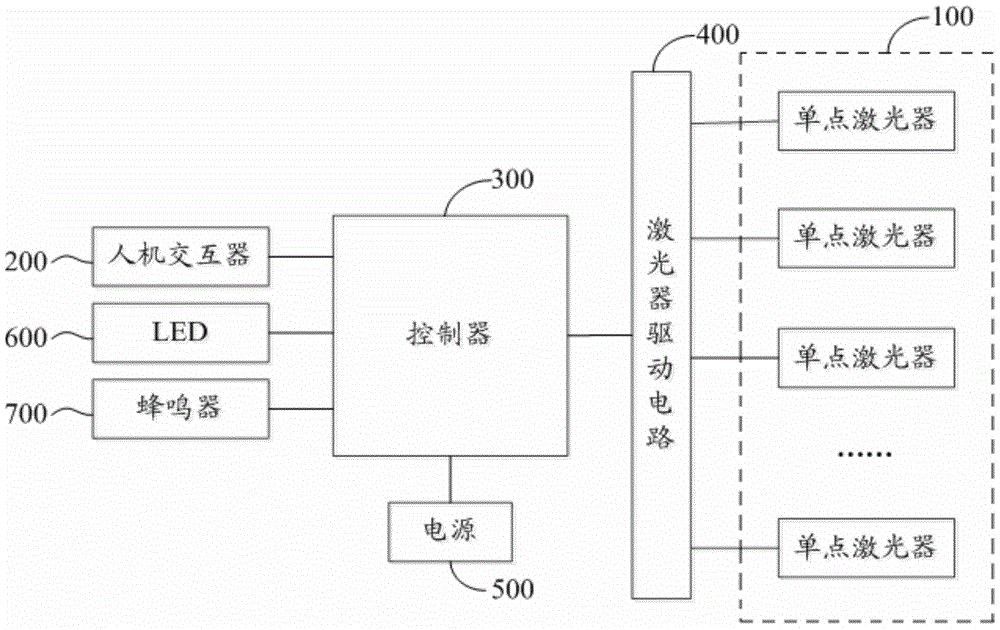

[0041] Embodiment 2 of the present invention perfects and supplements the multi-point laser in Embodiment 1, and discloses another structure of the multi-point laser, such as figure 2 As shown, it includes N single-point lasers 100 , a human-computer interface 200 , a controller 300 and a laser driving circuit 400 , and also includes a power supply 500 , an LED (Light Emitting Diode, light emitting diode) 600 and a buzzer 700 .

[0042] At the same time, the function of the controller 300 has been expanded: the controller 300 is also used to monitor the power of the power battery and the tilt angle of the multi-point laser, and when it is detected that the power of the power battery is not within the preset normal power range, or When the tilt angle of the multi-point laser is not within the preset normal angle range, an alarm signal is generated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com