Device and method for chemical hydride catalytic-hydrolysis hydrogen production suitable for onboard hydrogen source

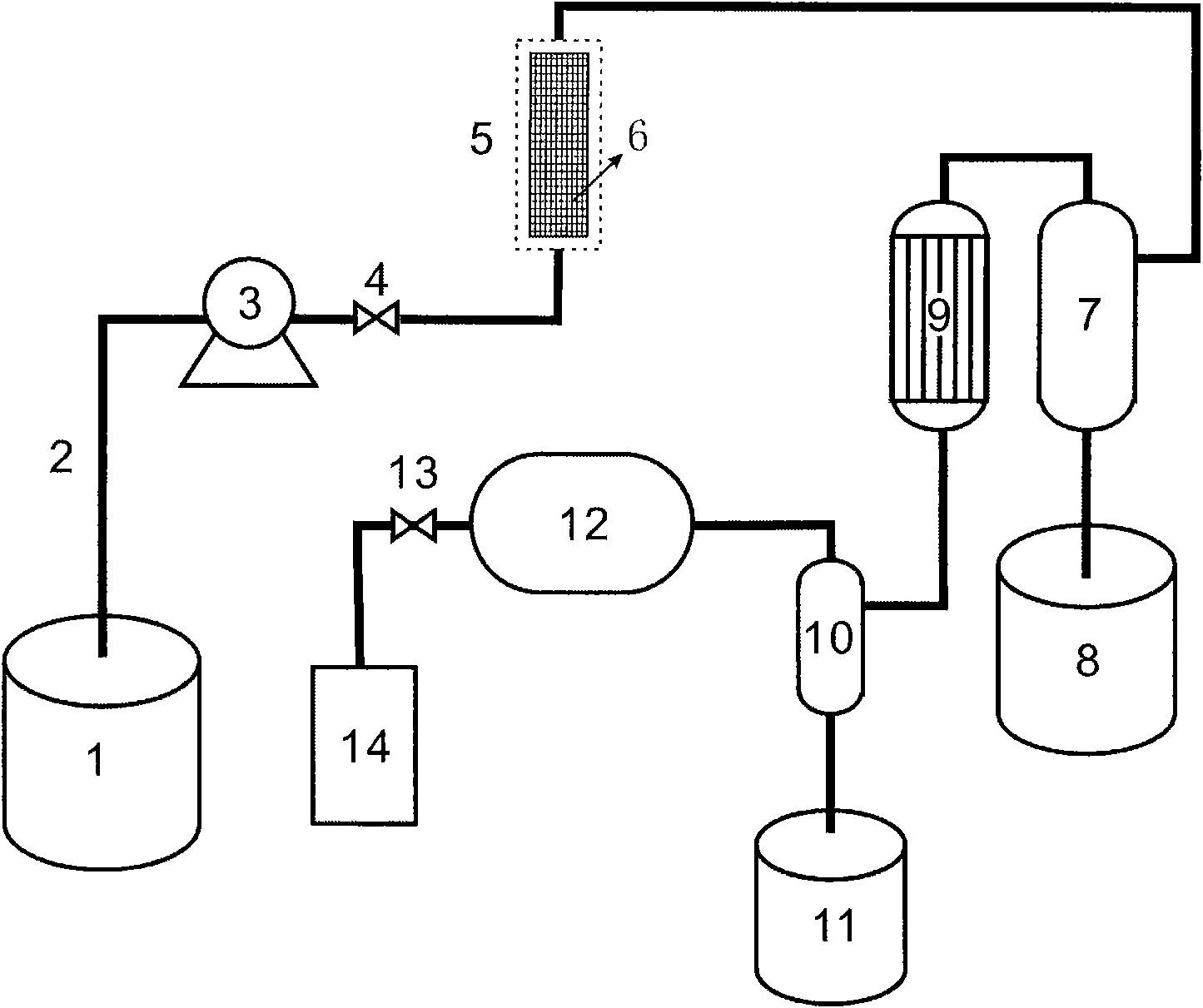

A hydrogen production device and a technology for catalytic hydrolysis, applied in the field of hydrogen storage and hydrogen production, can solve the problems of rapid response, reduced hydrogen storage density, and large fluctuation of hydrogen pressure, so as to improve the hydrogen production rate, reduce the volume, and increase the fuel. The effect of fluid velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Comparison of hydrogen production performance of devices using different types of catalytic reaction chambers.

[0050] Device and operating conditions:

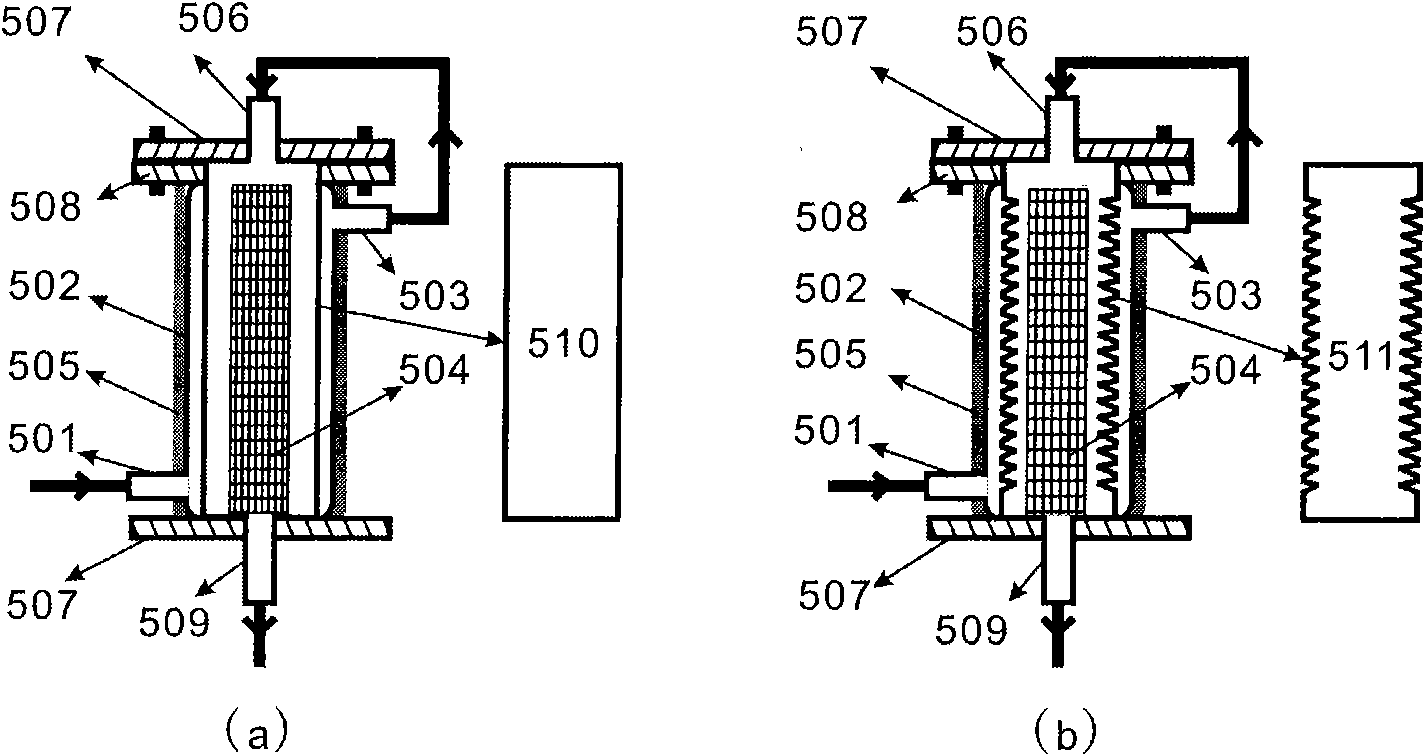

[0051] Three kinds of catalytic reaction chambers were compared and studied: the traditional straight-tube catalytic reaction chamber, and the straight-tube catalytic reaction chamber with a jacketed heat exchanger (such as figure 2 (a)) and a bellows-type catalytic reaction chamber with a jacketed heat exchanger (such as figure 2As shown in (b), the dimensions of the three catalytic reaction chambers are Φ20mm (inner diameter) × 1.5mm (wall thickness) × 300mm (length), and the material of the catalytic reaction chamber is stainless steel. Using Co-W-B / foam nickel catalyst (Co-W-B alloy loading capacity is 43wt.%), foam nickel carrier purity is 99.99wt.%, thickness is 1.88mm, surface density is 575g / m 2 , the average pore size is 0.2-0.5mm, and the catalyst mass is 33g. The composition of the fuel liquid used is:...

Embodiment 2

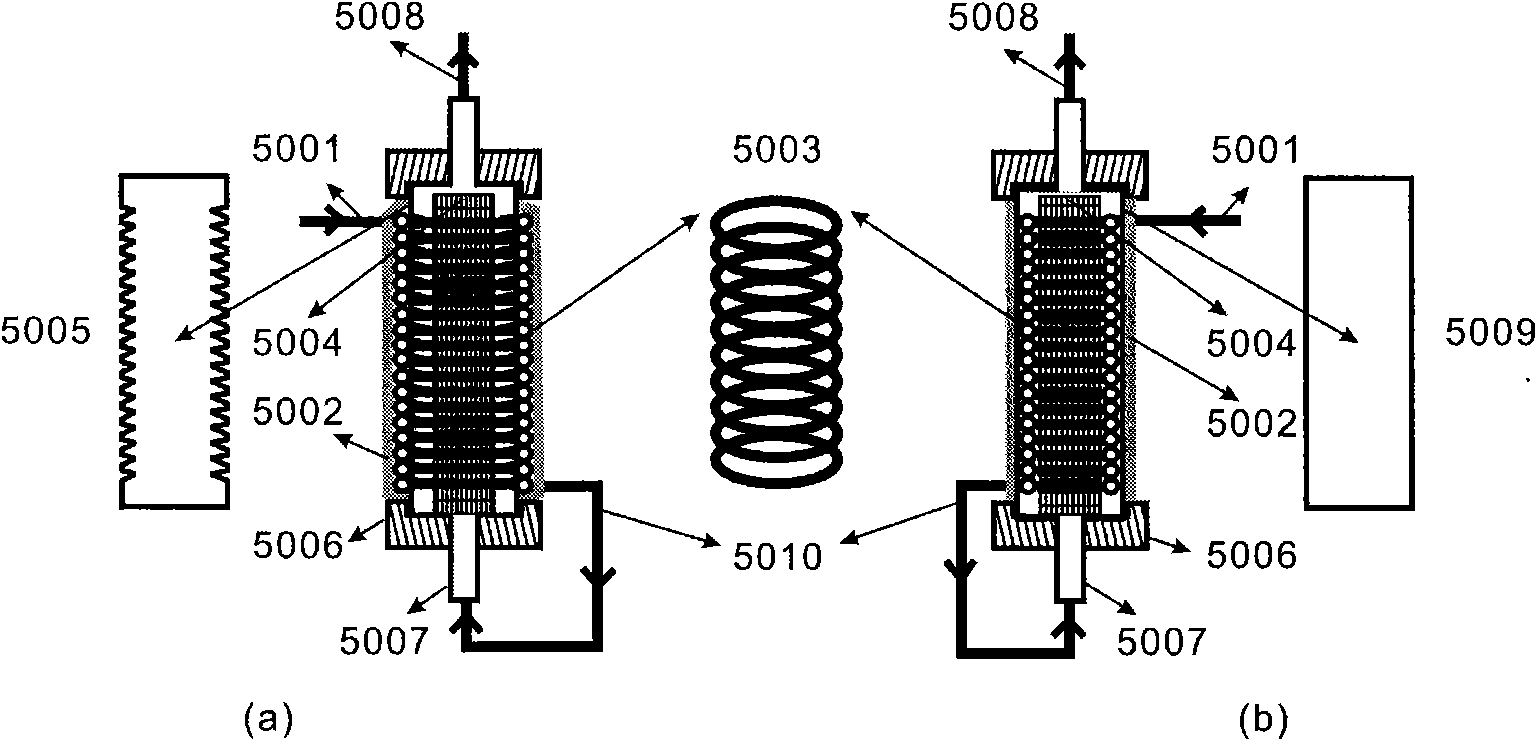

[0056] The hydrogen production performance of the traditional straight-tube catalytic reaction chamber, the bellows catalytic reaction chamber with external spiral heat exchanger and the straight-tube catalytic reaction chamber with built-in spiral heat exchanger were compared and studied.

[0057] Device and operating conditions:

[0058] Bellows catalytic reaction chamber with external spiral heat exchanger (such as image 3 (a) shown) and the device structure of the straight tube catalytic reaction chamber with built-in spiral heat exchanger (such as image 3 As shown in (b), the dimensions of the three catalytic reaction chambers are Φ20mm (inner diameter)×1.5mm (wall thickness)×300mm (length), and the material of the catalytic reaction chambers is titanium. Using Co-Ru / TiO 2 Catalyst (Co-Ru alloy loading is 14wt.%), TiO 2 The purity is 99.9wt.%, the average particle size is about 100 mesh, and the specific surface area is about 80m 2 / g, the catalyst mass is 55g, and ...

Embodiment 3

[0061] The effect of adding an automatic control unit on the response time of the hydrolysis hydrogen production unit was studied.

[0062] Device and operating conditions:

[0063] A bellows type catalytic reaction chamber with an external jacketed heat exchanger is constructed as follows: figure 2 As shown in (b), the reaction chamber size, material and device hydrogen production rate measurement method are the same as in Example 1. Using Ni-Pt / graphite catalyst (Ni-Pt load is 10wt.%), the purity of graphite support is 99.9wt.%, the average particle size is 50 mesh, and the specific surface area is 30m 2 / g, the catalyst quality is 65g, and the catalyst is coated with 100 mesh stainless steel mesh. The fuel used is 20wt.% NaBH 4 +3wt.% NaOH+77wt.%H 2 O, the operating conditions are 24°C and the pressure is 0.45MPa. After the hydrogen produced was dehydrated by a silica gel drier, the hydrogen production rate was measured by a gas mass flow meter.

[0064] Figure 7 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com