Determining device and method of water permeability coefficient of concrete

A technology of water permeability coefficient and measuring device, which is applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve the problems of complex measuring device, measurement result error, unstable performance, etc., and achieve high measurement accuracy , the liquid level is fast and stable, and the effect of continuous data recording

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

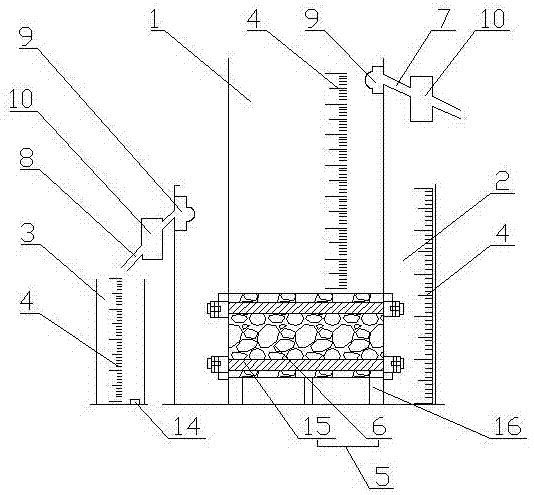

[0043] like figure 1 and 2 As shown, it includes a transparent cylinder 1, an overflow tank 2 and a measuring cylinder 3. The outer walls of the transparent cylinder 1, overflow tank 2 and measuring cylinder 3 are all engraved with a scale 4, and the transparent cylinder 1 is vertically arranged in the overflow tank 2, the upper and lower ends of the transparent cylinder 1 are open, wherein the lower opening of the transparent cylinder 1 is provided with a concrete sealing and fixing device 5; the outer wall of the upper part of the transparent cylinder 1 is provided with a cylinder overflow port 7, and the overflow The outer wall of the tank 2 is provided with an overflow tank overflow port 8, wherein the measuring cylinder 3 is arranged below the overflow tank overflow port 8, and the cylinder overflow port 7 and the overflow tank overflow port 8 are sequentially installed with Rotameter 9 and liquid flow automatic controller 10; Liquid flow automatic controller 10 is made ...

Embodiment 2

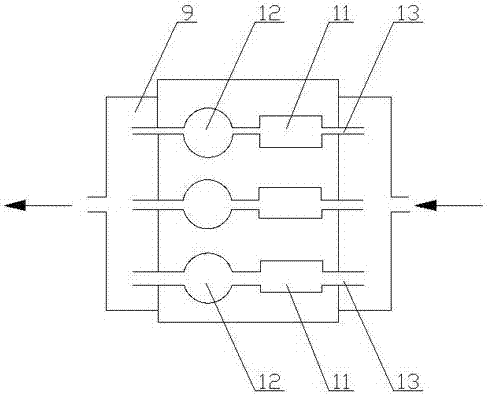

[0046] like figure 2 As shown, compared with Embodiment 1, this embodiment optimizes the liquid flow automatic controller 10, the time relay 11, the solenoid valve 12 and the pipeline 13 form a flow control path, and the liquid flow automatic controller 10 is provided with two parallel connections. The flow control path above.

[0047] In this embodiment, the connection of the pipeline 13 can be controlled by the time relay 11 and the solenoid valve 12, thereby controlling whether the cylinder overflow port 7 or the overflow tank overflow port 8 is conducting.

Embodiment 3

[0049] like figure 2As shown, compared with Embodiment 2, the present embodiment optimizes the liquid flow automatic controller 10, and three flow control passages are arranged in parallel, and the diameters of the pipes 13 of the three flow control passages arranged in parallel are respectively 15 mm, 20 mm and 25mm.

[0050] In this embodiment, the flow rate can be adjusted through three different flow control channels, so that the liquid level can be quickly stabilized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com