Vortex tube with axial cold and heat switching mechanism and heat exchange system with same

A technology of cooling and heating switching and vortex tubes, which is applied in the direction of refrigerators, machine operation modes, compressors, etc., can solve the problems of increasing the complexity of operations, increasing the overall cost of equipment, and unfavorable operations for ordinary users, achieving strong practicability, Save manpower and improve adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

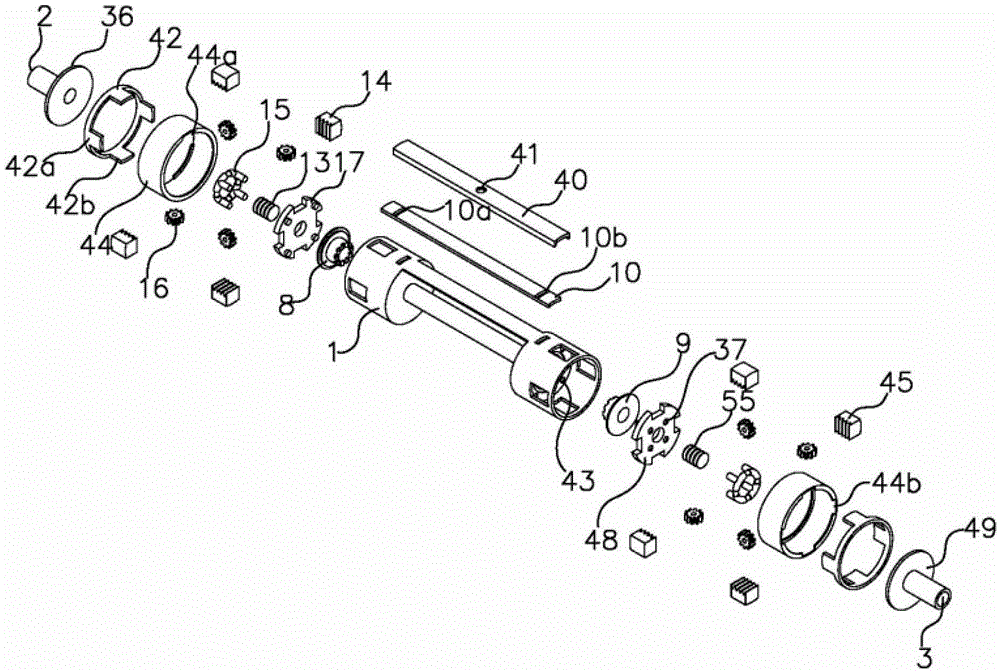

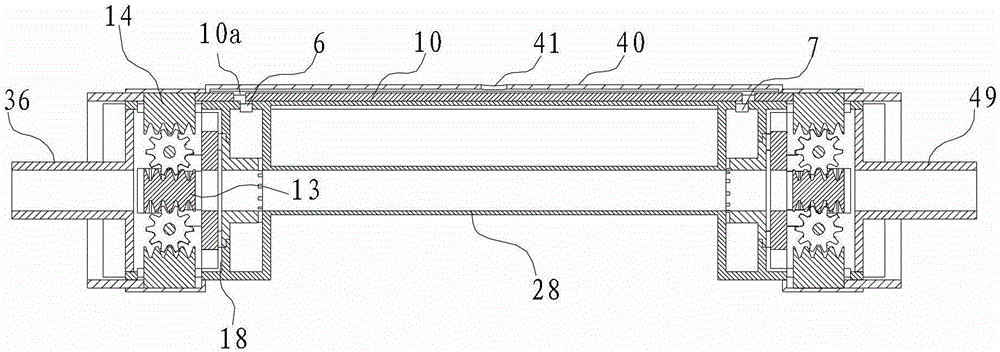

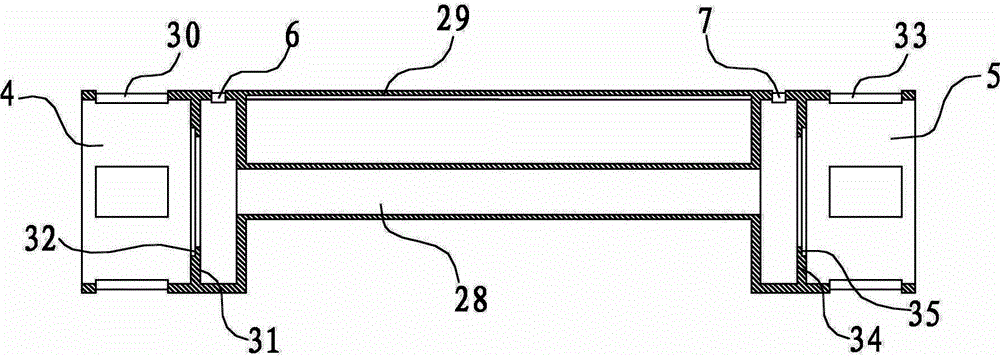

[0038] Such as figure 1 , figure 2 , image 3 , Figure 5 Shown: a vortex tube with an axial cooling and heating switching mechanism, including a vortex chamber 1, the two sides of the vortex chamber 1 are respectively equipped with a first air outlet 2 and a second air outlet 3, and the vortex chamber 1 has interconnected The first working chamber 4 and the second working chamber 5 are respectively provided with a first air inlet 6 and a second air inlet 7 on the walls of the first working chamber 4 and the second working chamber 5, and the first working chamber 4 and the second working chamber 5 are respectively provided with a first vortex separator 8 and a second vortex separator 9 corresponding to their respective air inlets; each vortex separator has a fluid channel 11 and is arranged on the fluid channel 11 side wall swirl injection channel 12; swirl chamber 1 is provided with a seal 10 for selectively opening the first air inlet 6 or second air inlet 7 along the ax...

Embodiment 2

[0053] Such as Figure 9 As shown, the difference with embodiment 1 is:

[0054] (1) The first working chamber 4 and the second working chamber 5 are separately provided with an adjusting plate 22 and an adjusting plate 50 for adjusting the flow rate of the internal hot air. The rocker arm 24 and the rocker arm 51 of the cavity side wall. Four positioning protrusions are respectively fixed on the opposite sides of the adjusting plate 22 and the adjusting plate 50;

[0055] (2) cut-off plate 57 replaces cut-off plate 17, cut-off plate 58 replaces cut-off plate 48, and the side opposite to cut-off plate 57 and cut-off plate 58 is respectively provided with the positioning groove that engages with support 59 and support 60 mutually, and another There is no longer a snap-fit relationship between the side and the corresponding working chamber.

[0056] (3) The bottom of the first working chamber 4 and the second working chamber 5 respectively offers a small hole 61 for the roc...

Embodiment 3

[0061] A heat exchange system with a vortex tube, comprising a vortex tube and a heat exchanger connected by pipelines, the vortex tube is the vortex tube with an axial cooling and heating switching mechanism described in Embodiment 1. The connections between the vortex tube and the heat exchanger are all prior art, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com