Fuel containment and recycling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

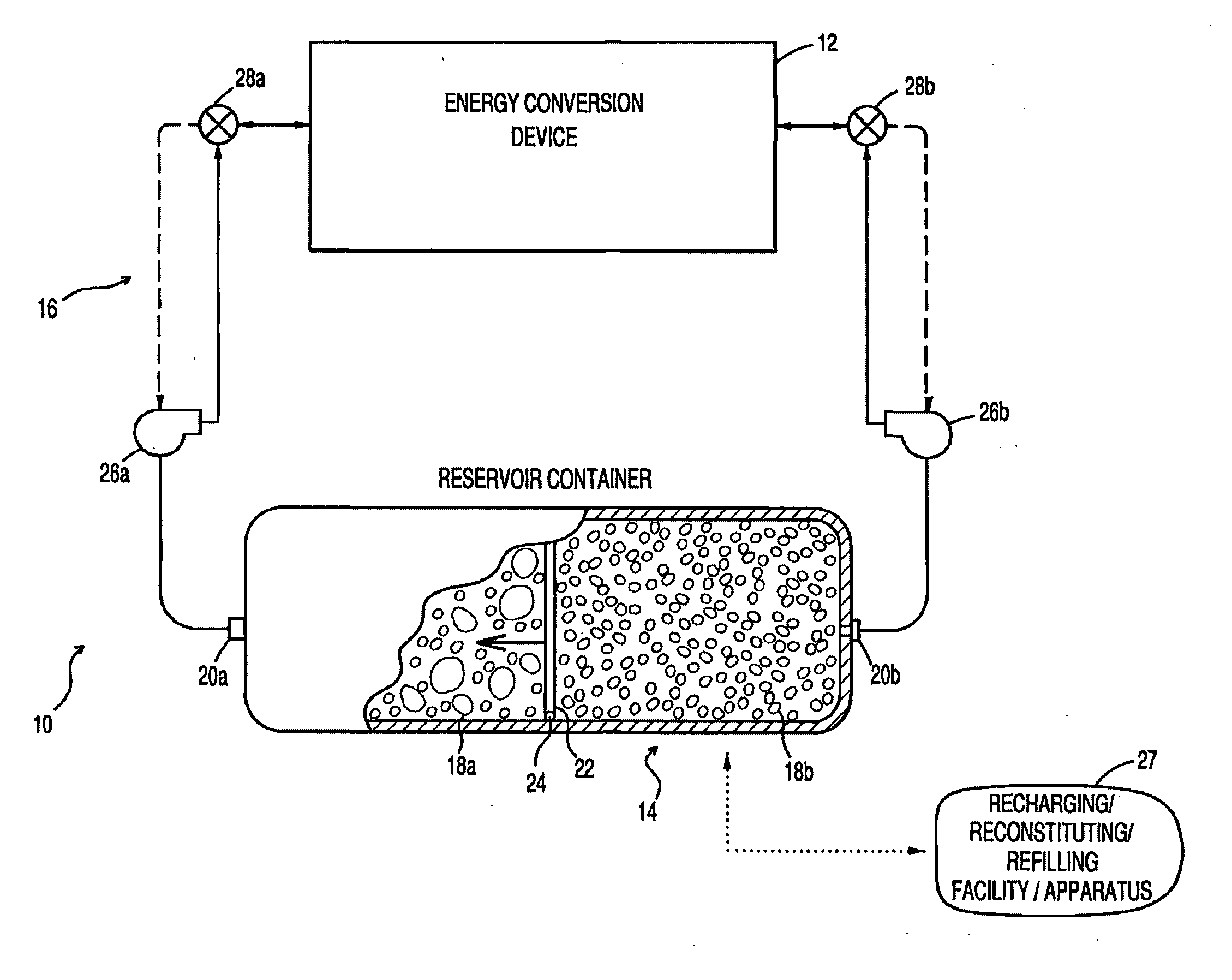

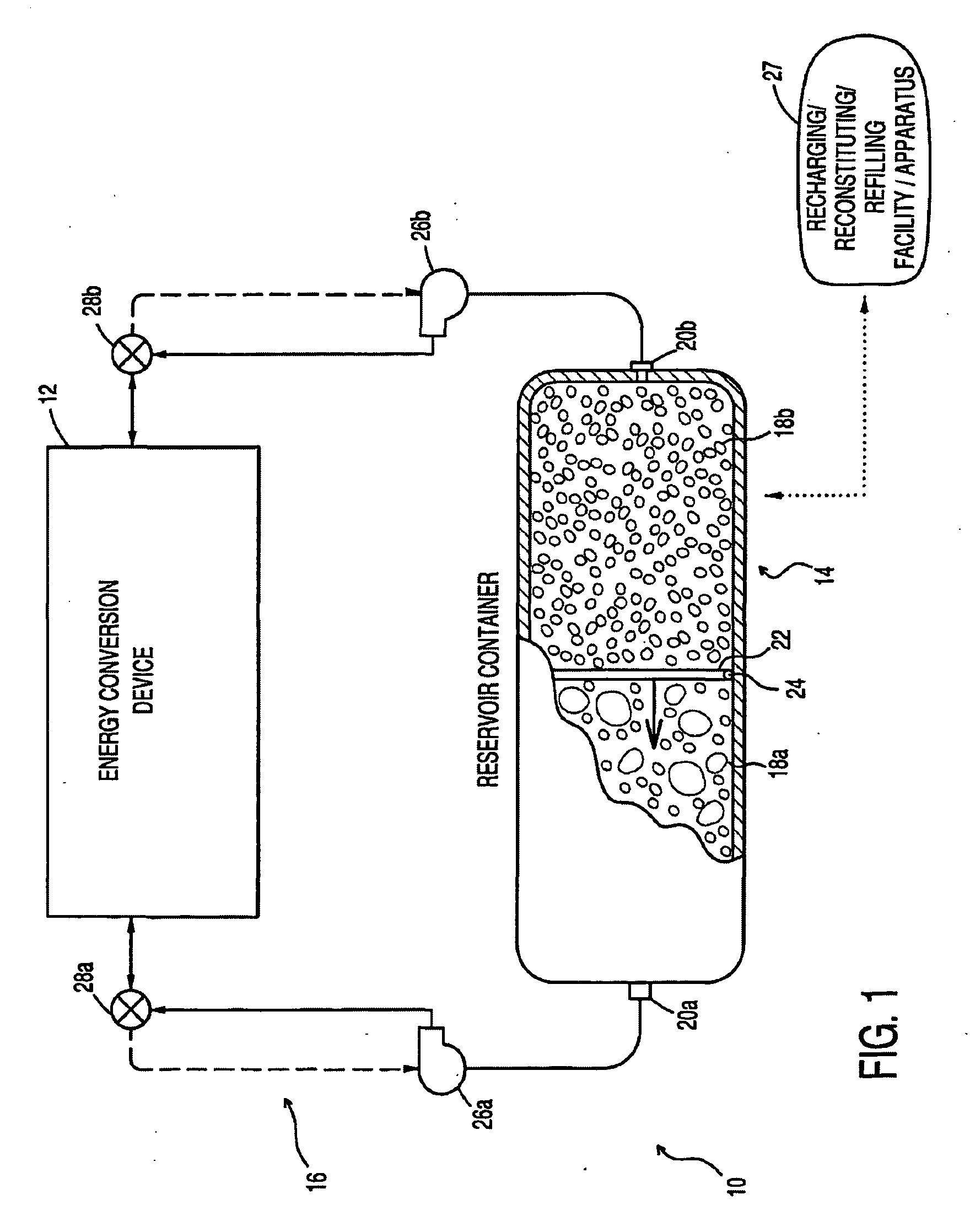

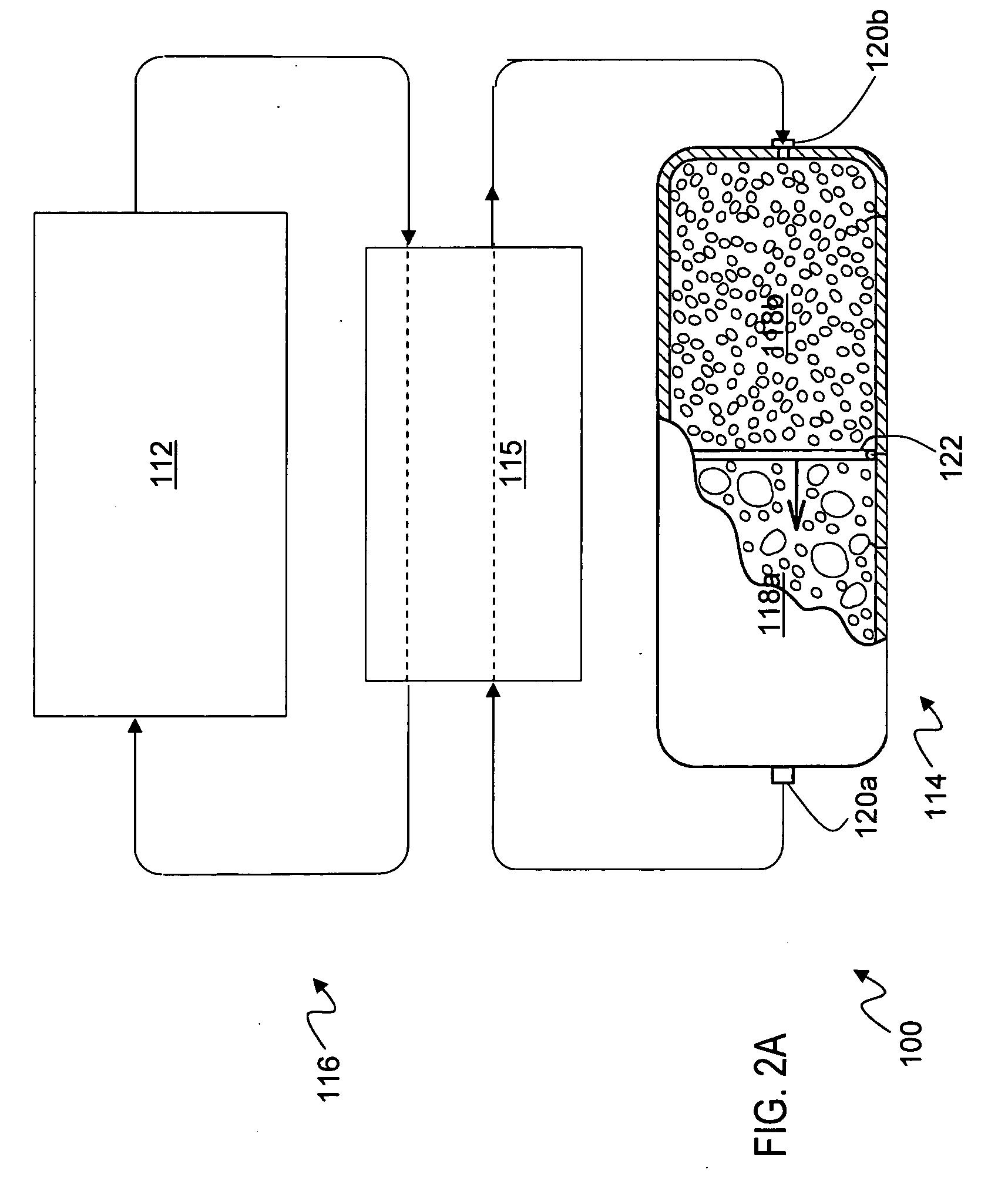

[0062] Referring now to FIG. 2A, there is shown a schematic of a representative fuel cell power system 100 in a first embodiment including an auxiliary tank. System 100 comprises an energy conversion device 112, a reservoir container 114, an auuxuliary tank 115, and a fluid circuit generally denoted by the reference numeral 116. The energy conversion device 112 converts fuel into energy and exhaust, and can be any one of a variety of devices as discussed above with respect to FIG. 1. The reservoir container 114 is partitioned into at least two chambers 118a, 118b, for respectively holding varying quantities of fuel and exhaust. In this regard, the chambers 118a, 118b are adapted to vary inversely in volume such that as fuel is first dispensed from chamber 118a, an amount of exhaust is collected in chamber 118b. After the entire quantity of fuel from chamber 118a has been supplied to the energy conversion device 112 and chamber 118b has filled with exhaust, the reservoir container ca...

second embodiment

[0064] Referring now to FIG. 3, there is shown a schematic of a representative fuel cell power system 30 in a The power system 30 generally includes a reservoir container 32, power stack 34, flow circuit 36 and valve / insulating system (ISS) 38. The reservoir container includes a pair of chambers 40a, 40b of inversely variable volume as described above with respect to the general embodiment illustrated in FIG. 1. As shown in FIG. 3, fluid anode material is initially contained in chamber 40a. The flow circuit 36 contains a pump 42 (a single pump is depicted, but more than one may be installed, with the additional pump(s) located proximal to chamber 40a) to drive the fluid through the system. The fuel is initially dispensed from chamber 40a to the ISS 38. The ISS 38 includes a fuel feed conduit 44 having respective branch lines 46a-d to communicate the anode paste (or reaction products upon reversal of the cycle) from the reservoir container 32 to a plurality of corresponding cell ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com