MXene(Ti3C2)-loaded palladium catalyst and preparation method and application thereof

A palladium catalyst and loading capacity technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and the preparation of organic compounds, can solve pollution and other problems, and achieve the effects of simple operation, simple process flow, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

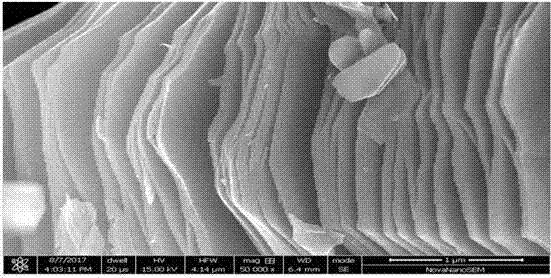

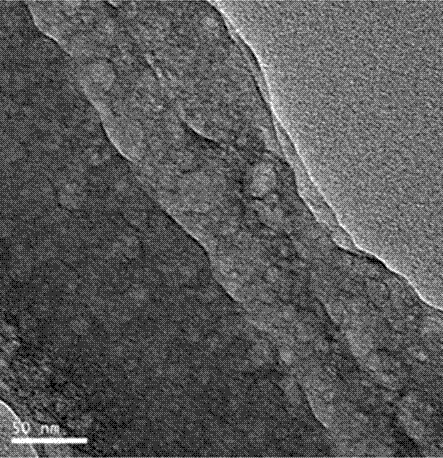

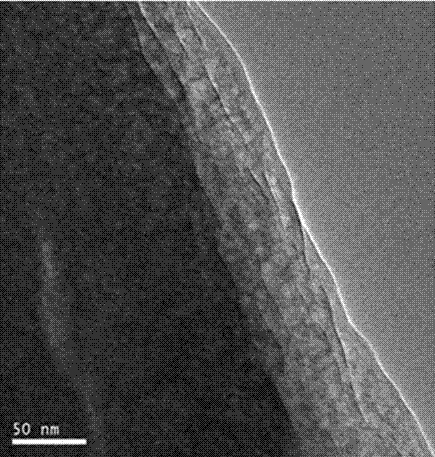

[0028] Embodiment 1: loading is 5% MXene (Ti 3 C 2 ) The preparation method of supported palladium catalyst is as follows:

[0029] Weigh 3.0g of Ti 3 AlC 2 As the raw material, put it in a 50 mL polytetrafluoroethylene cannula, then add 30 mL of 40wt.% HF solution dropwise into the cannula under stirring, and etch at room temperature for 24 hours; the etched powder Rinse with a large amount of deionized water until neutral, then put it into a freeze dryer, set the temperature of the cold well at -40°C, and freeze-dry for 20 hours to obtain MXene (Ti 3 C 2 ), weigh the dried MXene (Ti 3 C 2 ) powder 2.0g and 0.213g of palladium acetate were placed in a 100mL round-bottomed flask, and an excess amount of deionized water was added under low-speed stirring, stirred at a low speed in an oil bath at 60°C, and immersed for 12 hours. Evaporate to dryness under reduced pressure at 55°C, then dry in vacuum at 60°C overnight, roast in a muffle furnace at 250°C for 3 hours to remo...

Embodiment 2

[0030] Embodiment 2: loading is 2% MXene (Ti 3 C 2 ) The preparation method of supported palladium catalyst is as follows:

[0031] Weigh 3.0g of Ti 3 AlC 2 As the raw material, put it in a 50 mL polytetrafluoroethylene cannula, then add 30 mL of 40wt.% HF solution dropwise into the cannula under stirring, and etch at room temperature for 24 hours; the etched powder Rinse with a large amount of deionized water until neutral, then put it into a freeze dryer, set the temperature of the cold well at -40°C, and freeze-dry for 20 hours to obtain MXene (Ti 3 C 2 ). Weigh the dried MXene (Ti 3 C 2 ) powder 2.0g and 0.085g of palladium acetate were placed in a 100mL round-bottomed flask, and an excess amount of deionized water was added under low-speed stirring, stirred at a low speed in an oil bath at 60°C, and immersed for 12 hours. Evaporate to dryness under reduced pressure at 55°C, then dry in vacuum at 60°C overnight, roast in a muffle furnace at 250°C for 3 hours to rem...

Embodiment 3

[0033] Get the MXene (Ti) prepared in Example 1 3 C 2 ) 0.0425g of palladium catalyst with a loading capacity of 5%, 67 mL of water, and 0.3g of vanillin were added to the reactor, and the air in the reactor was replaced by hydrogen for 5 times, then the temperature was set at 100°C, the pressure was 0.3 MPa, and the reactor was sealed. , stirring speed 900 rpm, reacted for 0.5h, cooled to room temperature with cold water, took out the reaction solution, filtered, the filter cake was used as a catalyst, and could be recycled and applied mechanically. Add 15 mL of ethyl acetate to the filtrate, fully extract and separate, and take the organic phase Atmospheric pressure distillation, take 200 ~ 220 ℃ distillate, get 4-methyl guaiacol. The results of gas chromatography-mass spectrometry analysis showed that the conversion rate of vanillin was 100%, and the selectivity of 4-methylguaiacol was 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com