Hybrid material of polypyridine zinc complex modified MIL-101, preparation method and application in catalyzing degradation of organic phosphorus

A polypyridine zinc and hybrid material technology, which is applied in the field of organic hybrid materials, can solve the problems of unstable existence of active species LM-OH, low catalytic hydrolysis rate and efficiency, and achieve good catalytic cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of each buffer solution involved in the present invention is as follows:

[0044] 50mM N-ethylmorpholine buffer solution with pH 7.0: Weigh 288mg of N-ethylmorpholine into a beaker filled with 45ml of distilled water, adjust with 1mol / L hydrochloric acid or 1mol / L sodium hydroxide The pH of the solution was close to 7.0, transferred to a 50 ml volumetric flask, a small amount of water for rinsing the flask was also added to the volumetric flask, and the volume was adjusted to 50 ml. Then use a small amount of 1mol / L hydrochloric acid or 1mol / L sodium hydroxide to adjust the pH of the solution to 7.0.

[0045] 50mM N-ethylmorpholine buffer solution with pH 8.0: Weigh 288mg of N-ethylmorpholine into a beaker containing 45ml of distilled water, adjust with 1mol / L hydrochloric acid or 1mol / L sodium hydroxide The pH of the solution was close to 8.0, transferred to a 50 ml volumetric flask, a small amount of water for rinsing the flask was also added t...

Embodiment 1

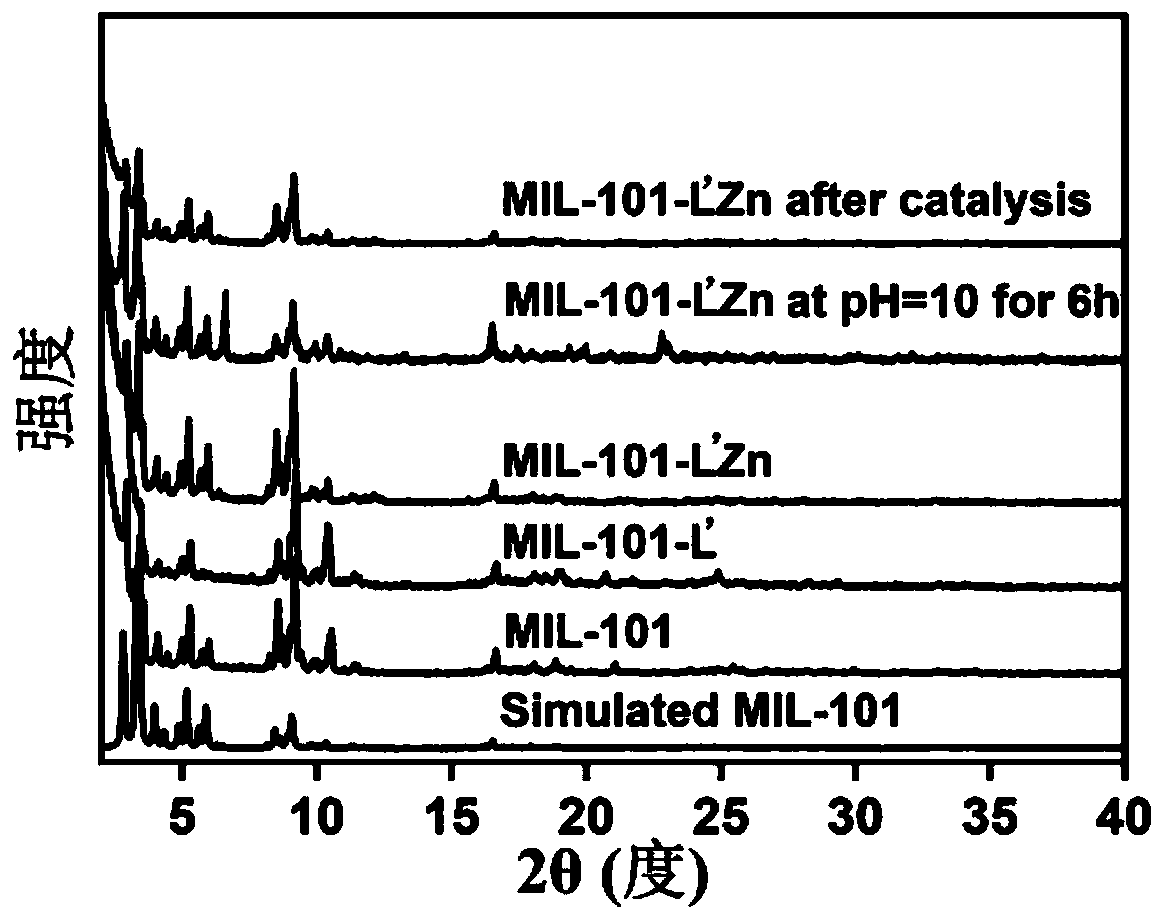

[0049] A kind of preparation method of the hybrid material of polypyridine zinc complex modification MIL-101, comprises the following steps:

[0050] (1) Preparation of MIL-101 activated by decoordination water: Weigh 4.33g (10.82mmol) chromium nitrate nonahydrate and 1.80g (10.83mmol) terephthalic acid and ultrasonically disperse them in 52mL of deionized water, and ultrasonically disperse evenly , and 0.3 mL (1.5 mmol) of 42% HF aqueous solution was added dropwise. The above prepared solution was added into a polytetrafluoroethylene-lined autoclave, and heated in a 473K oven for 8 hours. In order to remove impurities in the pores of MIL-101, reflux with 450 ml of deionized water for 24 hours, filter while hot, and then use 450 ml of ethanol to reflux the MIL-101 twice, each time for 24 hours, use hot ethanol Washing and filtering, the obtained crystals are reused containing NH 4 The aqueous solution of F was refluxed for 24 hours, filtered while hot, and the obtained produ...

Embodiment 2

[0056] A kind of preparation method of the hybrid material of polypyridine zinc complex modification MIL-101, comprises the following steps:

[0057] (1) with step (1) in embodiment 1;

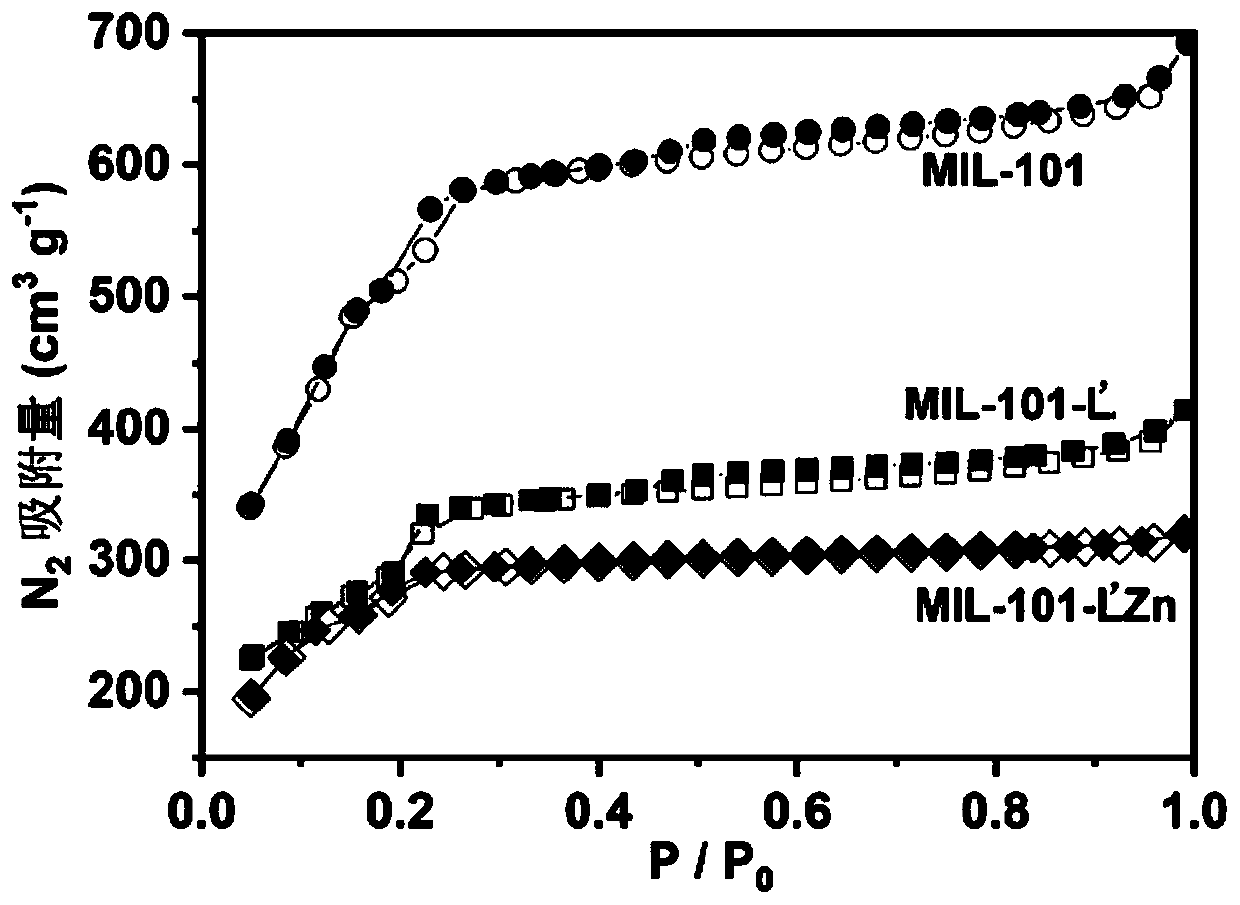

[0058] (2) Preparation of MIL-101-L': Dissolve 37.2 mg of ligand L, namely 4'-(4-pyridyl)-2,2':6',2"-terpyridine in 13 ml of anhydrous toluene Add 55.8 mg of MIL-101 activated by the above steps, ultrasonically disperse for 5 minutes, then reflux at 378K for 16 hours, centrifuge, wash with toluene and ethanol three times respectively, put it in a vacuum oven at 353K after centrifugation, and dry 12 hours.

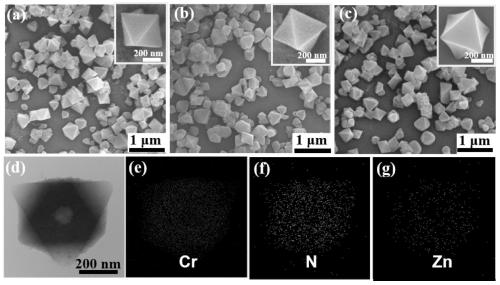

[0059] (3) Preparation of MIL-101-L'Zn: 32.8mg Zn(CH 3 COOH) 2· 2H 2 O was dissolved in 15 mL of methanol and water (v / v=1:1.1) mixed solvent, under vigorous stirring conditions, 65.5 mg of MIL-101-L' was added, heated at reflux at 343 K for 5 hours, centrifuged and washed three times with methanol , put into a 353K vacuum oven after centrifugation, and dry for 12 hours to obtain a gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com