Catalytic conversion method of hydrocarbon oil

A catalytic conversion method and catalytic cracking technology, applied in the field of catalytic conversion, can solve the problems of high hydrogen consumption, affecting conversion, etc., and achieve the effects of optimizing operating conditions, reducing hydrogen consumption, and high octane number.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

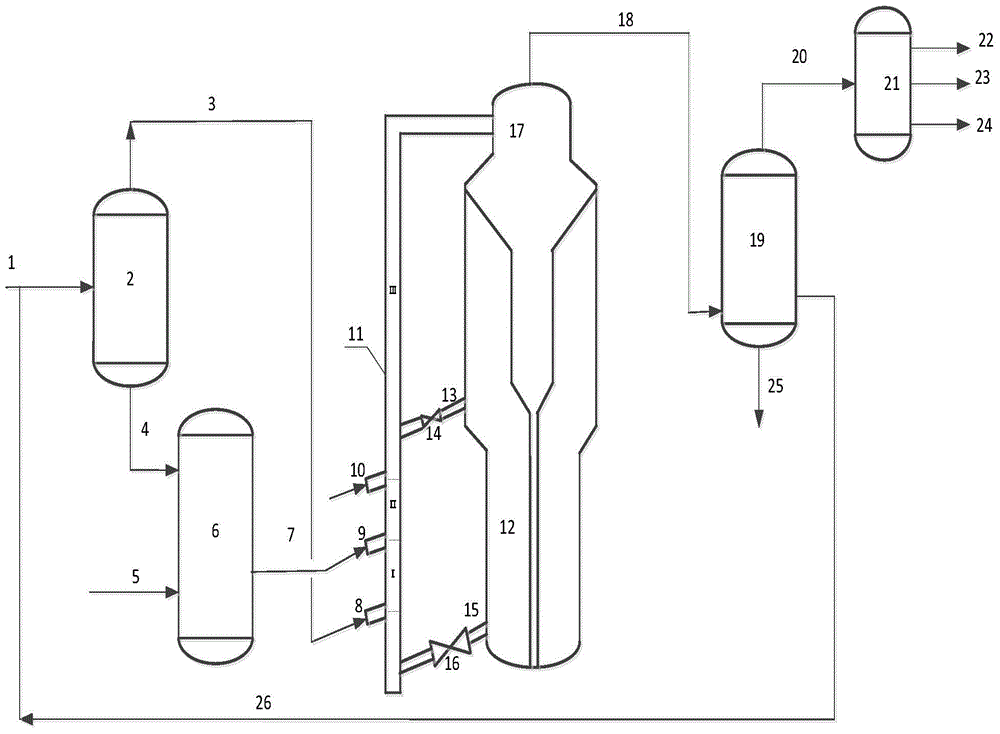

[0045] This embodiment illustrates adopting the present invention figure 1 method provided in . The distillation range cut-off temperature of the light cycle oil fractionation tower is 250°C.

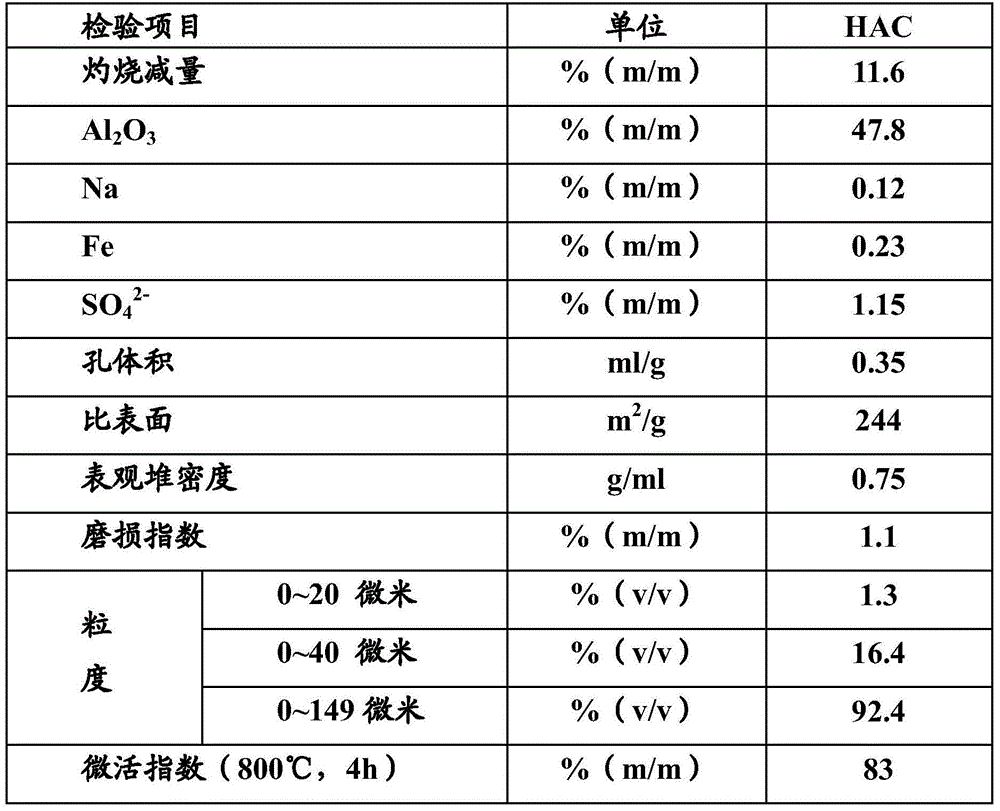

[0046] The heavy fraction of light cycle oil enters the medium-sized hydrotreating unit, and the test conditions of hydrotreating are: hydrogen partial pressure 8.0MPa; average bed reaction temperature 360°C, volume space velocity 0.5 hours -1 , hydrogen oil volume ratio 1100Nm 3 / m 3 . The dicyclic aromatics content in the hydrogenated heavy fraction was 8.0% by weight.

[0047] The main operating parameters of the catalytic cracking unit are shown in Table 3. The residence time of the reaction oil and gas is 0.2 seconds within the distance between the positions where the light fraction and the hydrogenated heavy fraction enter the riser. The residence time of the reaction oil gas is 0.2 seconds within the distance between the positions where the hydrogenated heavy distillate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com