Preparation method for 2400MPa class low-cost nano bainitic steel

A bainitic steel, low-cost technology, applied in the field of preparation of 2400MPa grade low-cost nano-bainite steel, can solve the problems of long preparation time, high preparation cost, high price of alloy elements, etc., and achieves good elongation, improved High efficiency and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

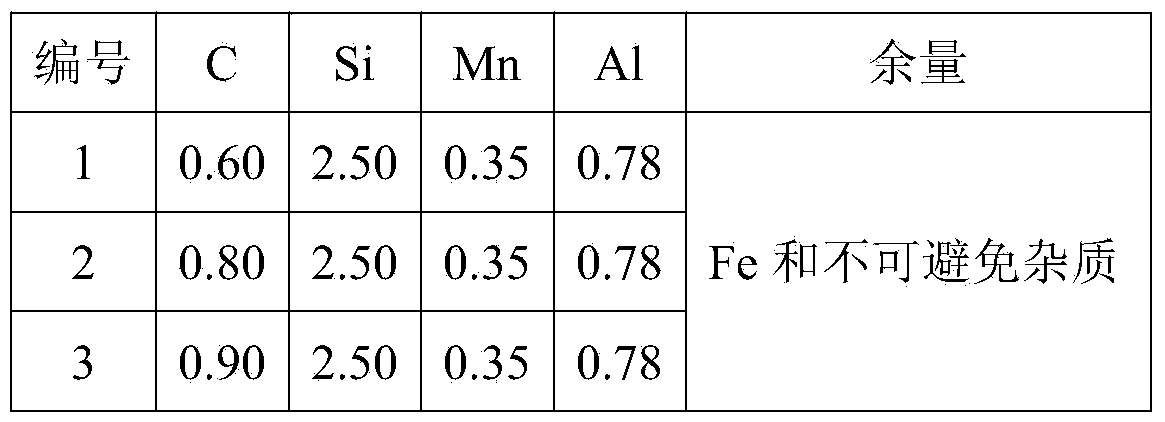

[0030] According to the chemical composition given in Table 1, the cast billet was forged into a forged billet by vacuum melting in an electromagnetic induction furnace for subsequent processes.

[0031] Table 1 is the mass percent of each composition

[0032] Table 1

[0033]

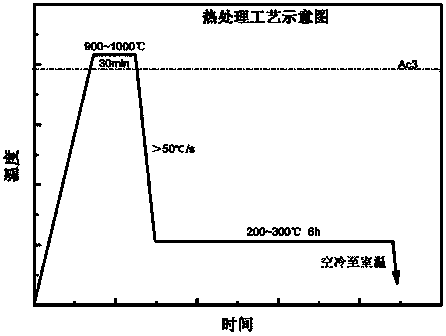

[0034]Heat the forged billets to 950°C for austenitization for 30 minutes, then take out the samples and put them directly into the salt bath quenching furnace for isothermal heat treatment. The holding temperature is 200-300°C, and the holding time is 6 hours. .

[0035] The present invention adopts different heat preservation temperatures for different samples, No. 1 is heat-preserved at 200°C and 300°C, No. 2 is heat-preserved at 230°C and 300°C, No. 3 is heat-preserved at 230°C and 300°C, and the heat preservation time is the same. The performance corresponding to different process parameters is shown in Table 2:

[0036] Table 2 shows the mechanical properties corresponding to the main proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com