Silicon hydrogel material having high oxygen permeability, corneal contact lens, and preparation method thereof

A corneal contact lens, silicon hydrogel technology, applied in glasses/goggles, instruments, optics, etc., can solve problems such as being unsuitable for industrialized large-scale production, complex monomer synthesis, low elastic modulus, etc., and achieve good penetration. Oxygen and hydrophilicity, simple process, good elongation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

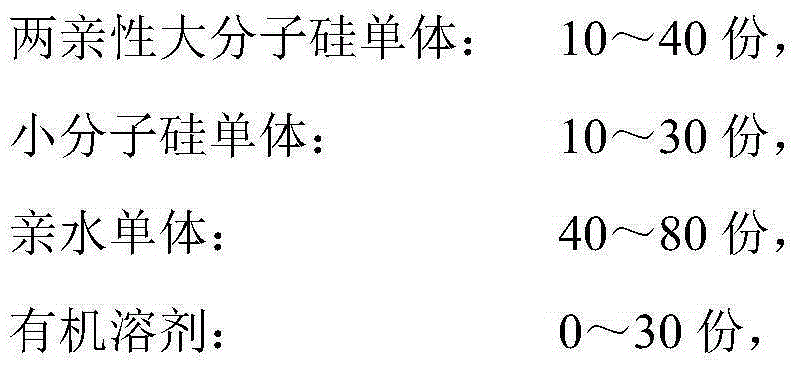

[0044] A silicone hydrogel material with high oxygen permeability provided in this embodiment is formed by polymerization reaction of the following components in parts by mass:

[0045]

[0046] Initiators and crosslinkers;

[0047] Among them, the sum of the mass parts of amphiphilic macromolecular silicon monomer, small molecular silicon monomer, hydrophilic monomer and organic solvent is 100 parts; 0.1% to 3% of the sum of the weight of amphiphilic macromolecular silicon monomers, small molecular silicon monomers, hydrophilic monomers and organic solvents; 0.1-3%.

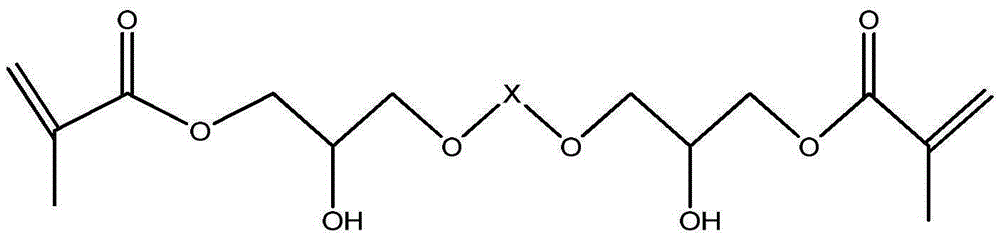

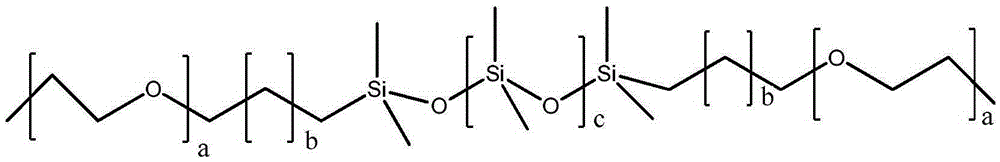

[0048] In above-mentioned embodiment 1, macromolecular silicon monomer has the molecular formula of following structure:

[0049]

[0050] or

[0051]

[0052] Wherein, the structural formula of X is as follows:

[0053]

[0054] Wherein, the value range of a is an integer ranging from 1 to 14, the value range of b is an integer ranging from 1 to 6, and the value range of c is an integer ranging ...

example 1

[0066] Take 13g diol (the structural formula is shown in the following formula W1), 20mL chloroform, 0.1g catalyst dibutyltin dilaurate, 3.1g isocyanoethyl methacrylate (IEM), mix well, and heat to reflux at 50°C for 10h. After the reaction, wash with petroleum ether, let stand to separate layers, take the lower layer liquid and distill under reduced pressure to obtain transparent amphiphilic macromolecular silicon monomer, which is marked as M1-W1.

[0067]

example 2

[0069] Take 13g of diol (the structural formula is as shown in the above formula W1), 30mL of tetrahydrofuran, 2.8g of glycidyl methacrylate (GMA), 0.5g of trifluoromethanesulfonic acid, magnetic stirring, reflux at 60°C for 30min, and depressurize after the reaction Distillation to obtain a transparent amphiphilic macromolecular silicon monomer, denoted as M2-W1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com