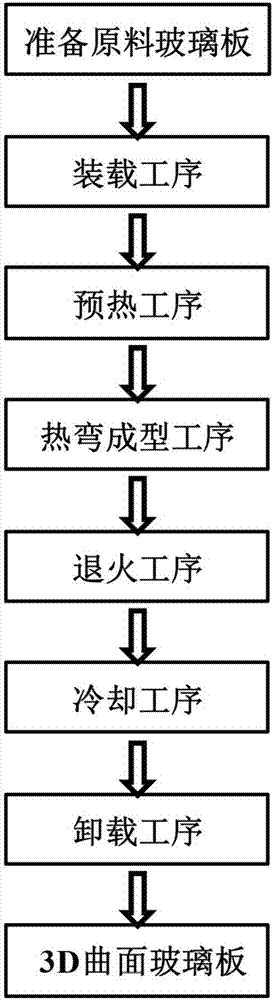

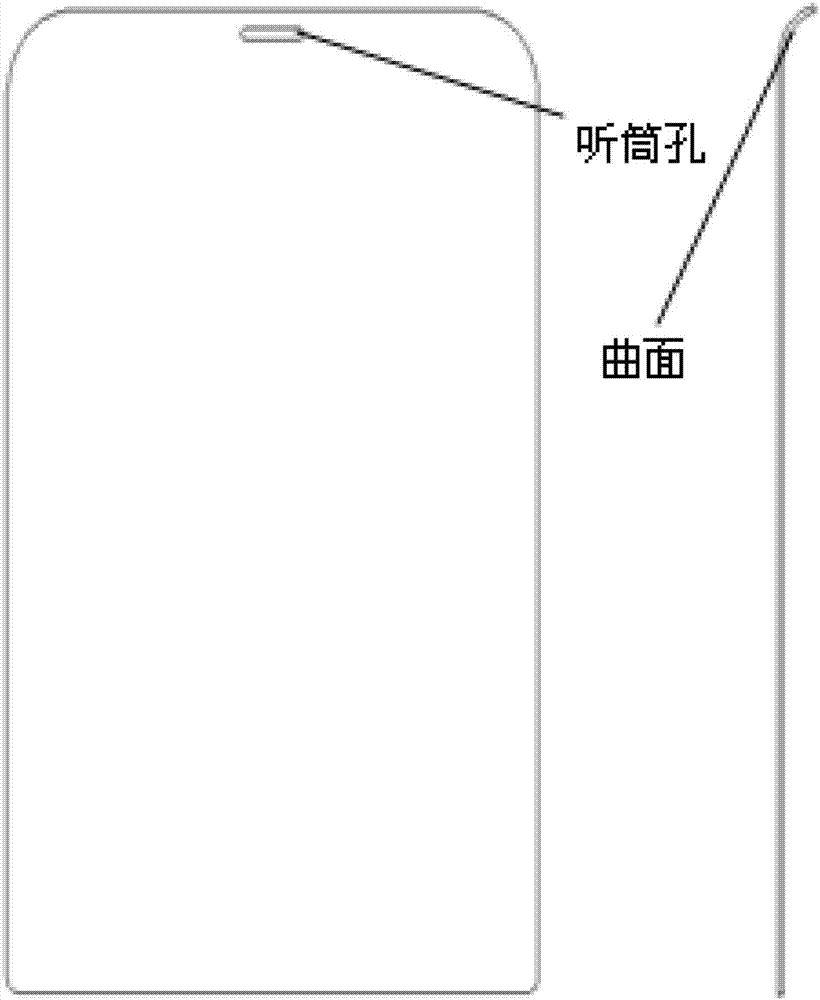

3D curved glass panel forming method and 3D curved glass panel obtained through forming method

A molding method and glass plate technology, applied in glass molding, glass reshaping, glass manufacturing equipment, etc., can solve the problems of rapid oxidation of molding molds, high molding costs, and inability to realize material/mold reuse, etc. To achieve the effects of inhibiting oxidation, realizing reuse, saving energy and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] The raw glass plate made according to the above-mentioned preparation method and proportion usually has the following characteristics:

[0082] ①Strain point: 550℃±20℃.

[0083] ②Annealing point: 605℃±20℃.

[0084] ③Deformation point: 685℃±20℃.

[0085] ④ Softening temperature: 830℃±20℃.

[0086] ⑤Thermal expansion coefficient: 98.0±2×10 -7 / °C.

[0087] (loading process)

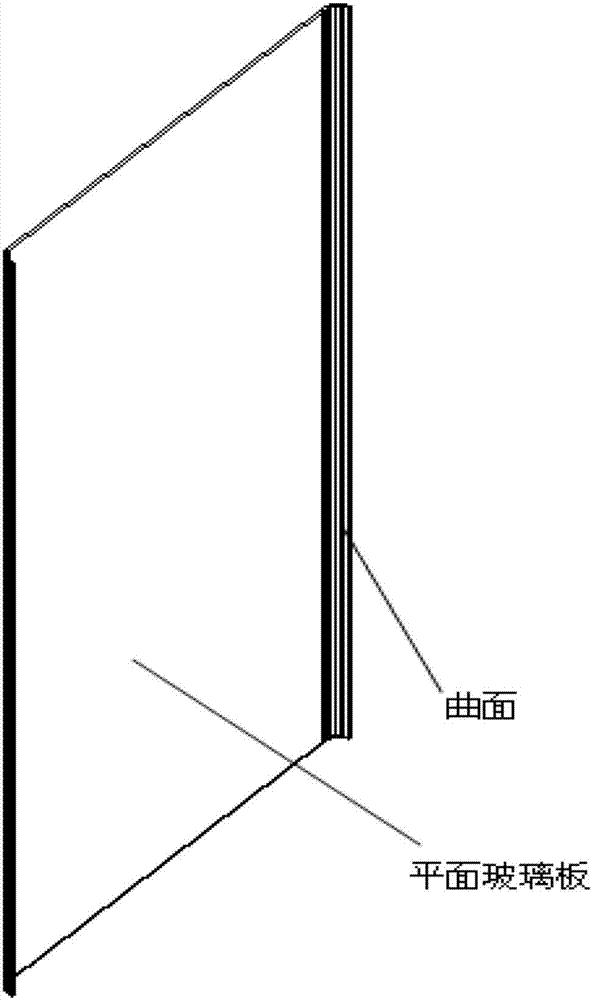

[0088] The loading step is a step of loading the forming mold and the raw glass plate. Specifically, the raw glass plate is put into the forming mold manually or mechanically, positioned and fixed, and then transported to the preheating zone. Specifically, the raw glass plate and the mold are transported to the hot bending equipment for preheating through the entrance of the hot bending equipment. heating zone. The material of the molding die is preferably ceramic or graphite, more preferably graphite. The size of the forming mold is determined according to the characteristics of the glass sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com